6 Interface Between CNC And PLC

6 - 17

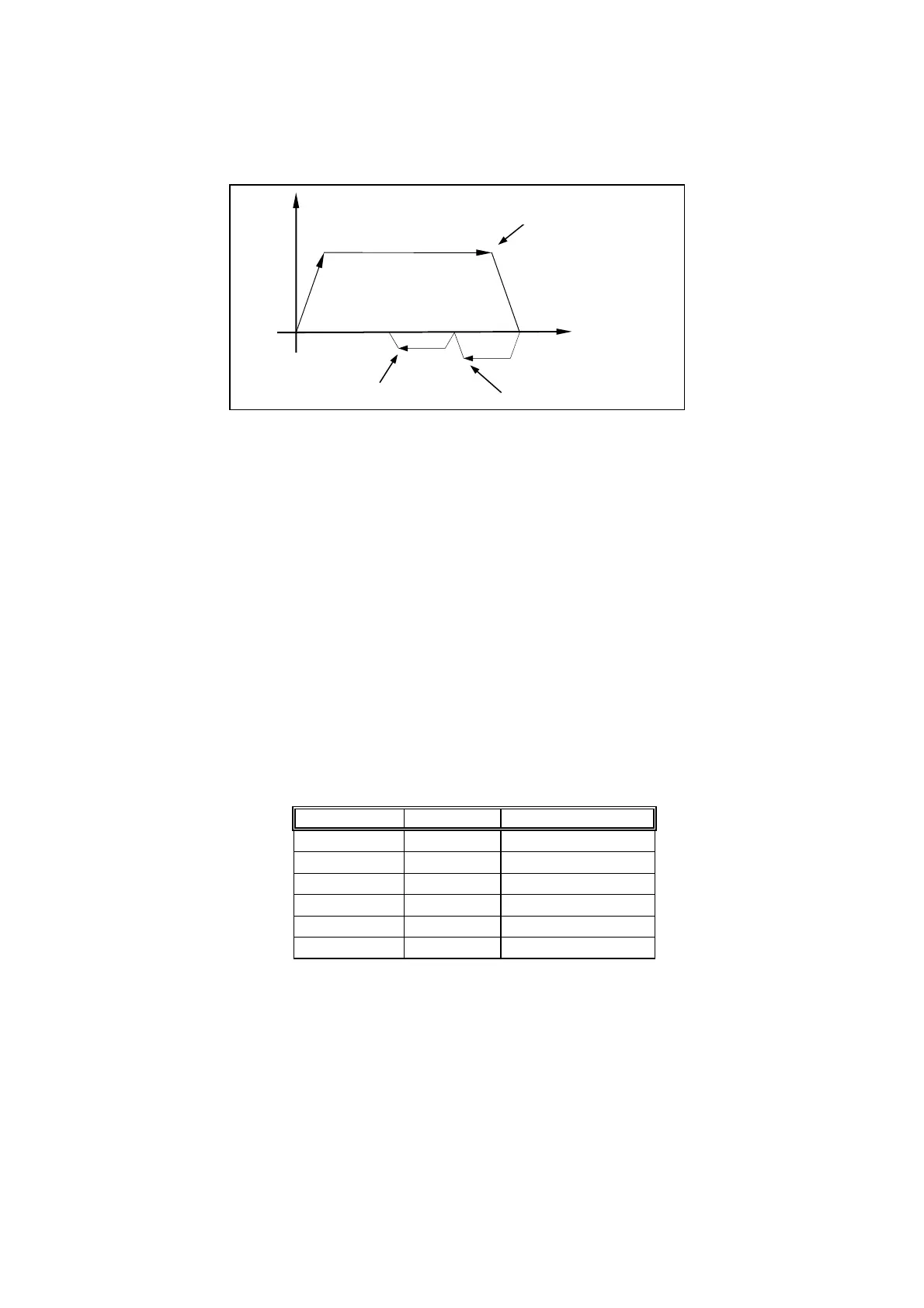

To find HOME position for Y-axis, the same procedures described above apply. Fig

6-7 is a typical time chart for HOME execution.

Fig 6-7 Time Chart for HOME Execution

• Specify Work Coordinate Group as Working Coordinate (C123)

Set the Current Program Position as Working Coordinate (C080~C081)

C123 = 1~0 (falling edge), use the data in MCM parameters as the current work

coordinate.

C080 = 1~0 (falling edge), use the current program position for X-axis as the work

coordinate origin.

C081 = 1~0 (falling edge), use the current program position for Y-axis as the work

coordinate origin.

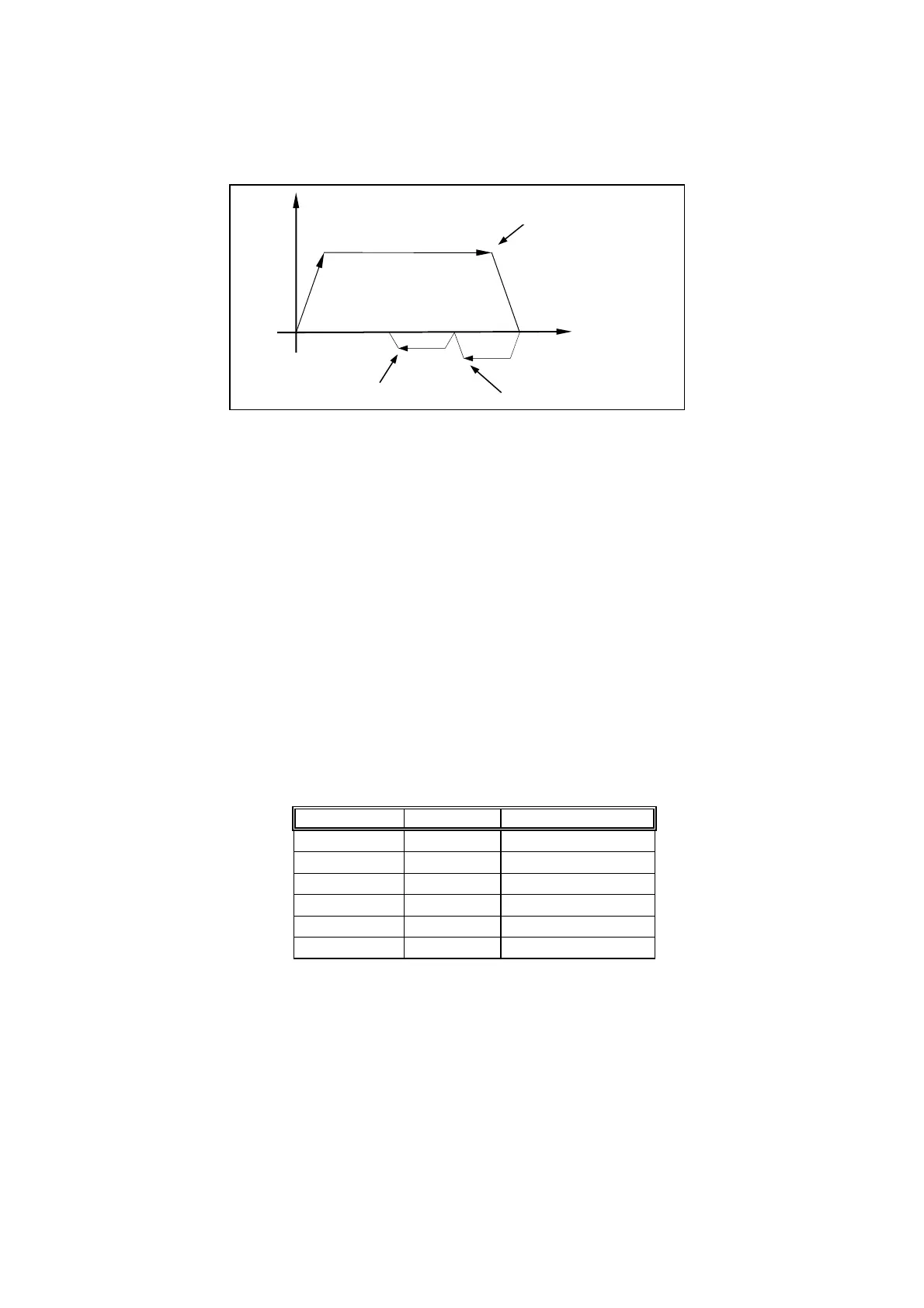

HUST H2N controller provides 6 groups of work coordinate (G54~G59) with their

location (with respect to HOME) data stored in MCM #1~#12 as shown in Table

below. Also shown is the group designation that is stored in register R228. (See

Table 6-4 for Registers) The default setting of work coordinate system is G54. To

change work coordinate, please follow one of the methods described below.

Work Coord. MCM No. Group No. by R228

G54

1

∼

2

0

G55

3

∼

4

1

G56

5

∼

6

2

G57

7

∼

8

3

G58

9

∼

10

4

G59

11

∼

12

5

Table 6-3 Work Coordinate

1. When in MDI or AUTO mode, execute one of G54~G59 function in the

program. Press “RESET” will restore the work coordinate back to default G54

system. For example, the program below is in G54 system when power-on. It

starts executing under AUTO mode and it changes to G55 system at block N10.

Once it finishes execution, press RESET will restore to G54 work coordinate

system.

Step1

Step3 Step2

Tool position

Tool

Speed

Leaving Home Limit Switch Found Encoder Index

Touching Home Limit Switch

Loading...

Loading...