HUST H2N Connection Manual

6 - 20

• Signal for Over-travel (OT) Limit Switch (C160~C163)

C160 =1, OT limit switch in the X+ side is touched.

C161 =1, OT limit switch in the X- side is touched.

C162 =1, OT limit switch in the Y+ side is touched.

C163 =1, OT limit switch in the Y- side is touched.

When the machine tool or the work table touches one of the hardware OT limit

switch, the corresponding C-bit sends a high (1) signal to CNC which produce a

CNC error signal to reset and stop the machine. When this happens, you have to

manually move (MDI mode) the tool away from the limit switch then RESET.

• Clear Error-count (C192~C193)

C192 =1, Clear error-count in X-axis.

C193 =1, Clear error-count in Y-axis.

• Positioning Execution in PLC Program (C208~C213)

(See Table 6-4 for Registers R160~R161, R180~R181)

C208 = 0 → 1, tool on X-axis moves to the position R180*10 with a speed of R160.

The S-bit S208=1 during command execution and S208=0 when execution

finished. This is done in PLC program.

C209 = 0 → 1, tool on Y-axis moves to the position R181*10 with a speed of R161.

The S-bit S209 = 1 during command execution and S209 = 0 when execution

finished. This is done in PLC program.

• Special C-bit for G28, G29 and G30 (C224~C225)

In addition to the normal application in the part program, G28, G29 and G30

functions can also be executed through C224~C225 (1 pulse signal) in PLC as

follows:

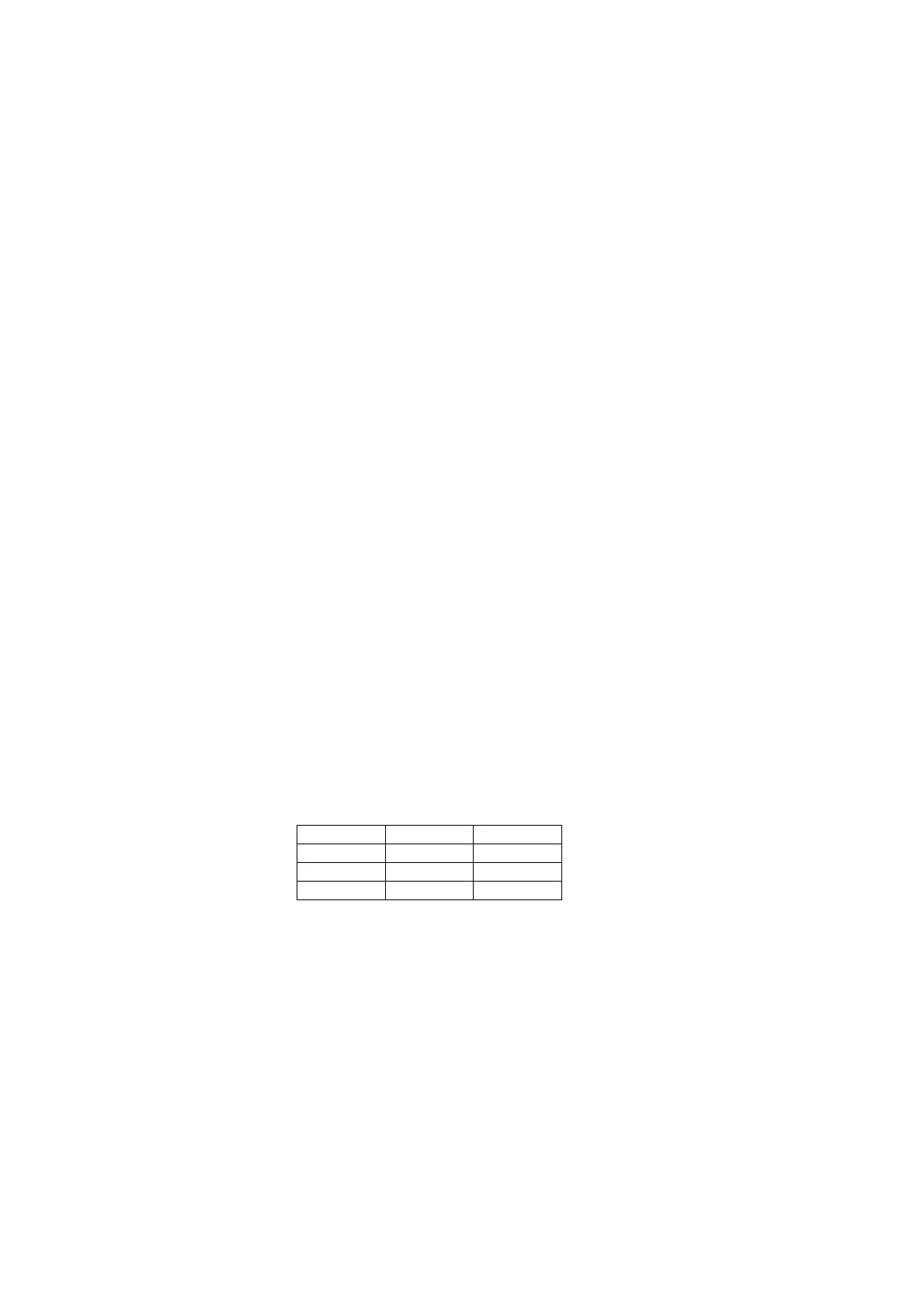

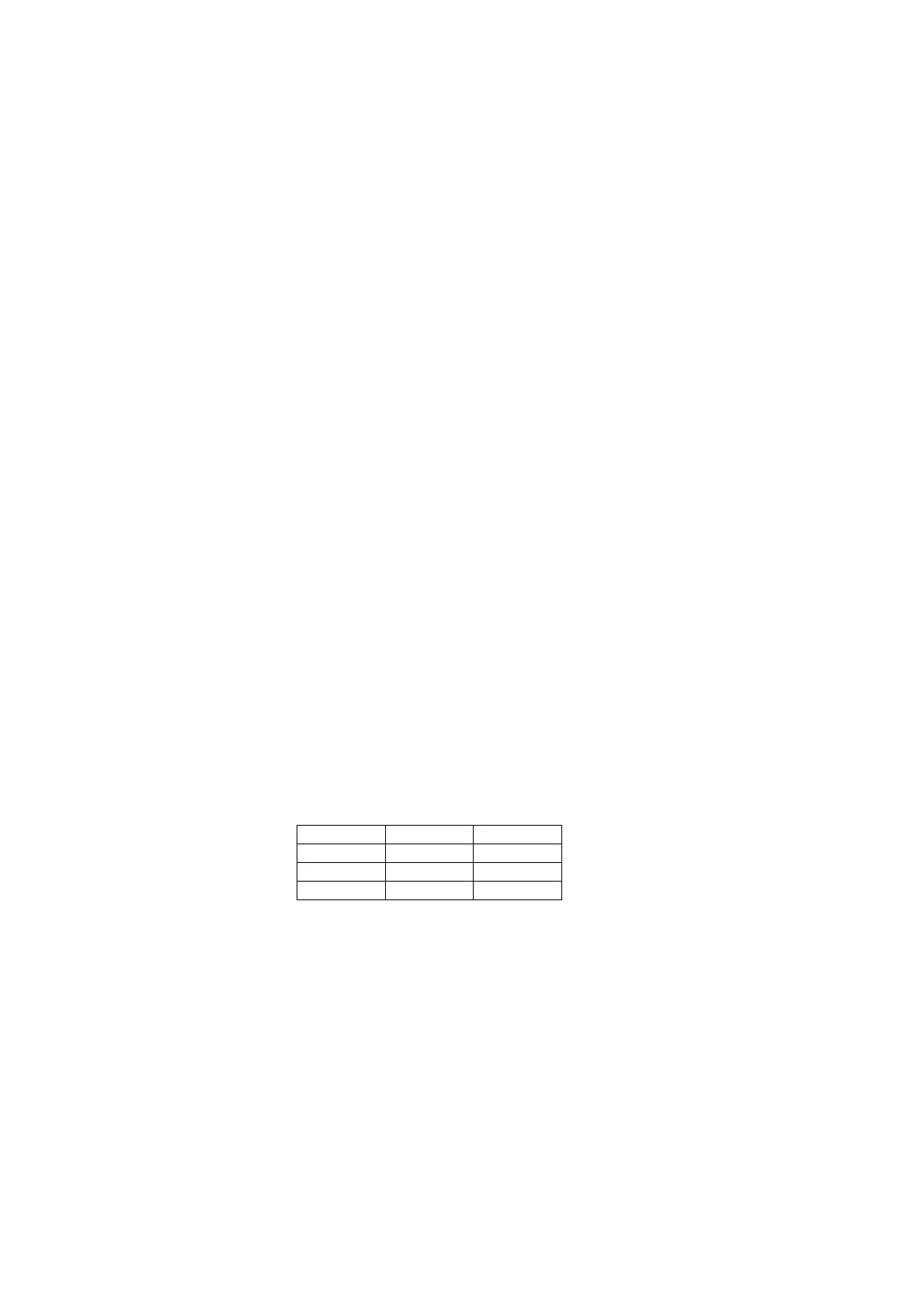

C225 C224

G28 0 1

G29 1 0

G30 1 1

When using C224 and C225, remember to specify the axis for G28~G30 in R232.

For example when C224=1 and R232=3 (see Table 6-4), G28 will be executed in X-

and Y-axis.

• Axial Motion Command in JOG Mode (C228)

When C228 =1 and R233≠0 (or R234≠0) in JOG mode, the designated axis will

move

(JOG feed) right away. The designated axis is determined by the binary bit being

stored in R233 or R234. Multiple axes can be put in motion simultaneously. For

Loading...

Loading...