HUST H2N Connection Manual

6 - 34

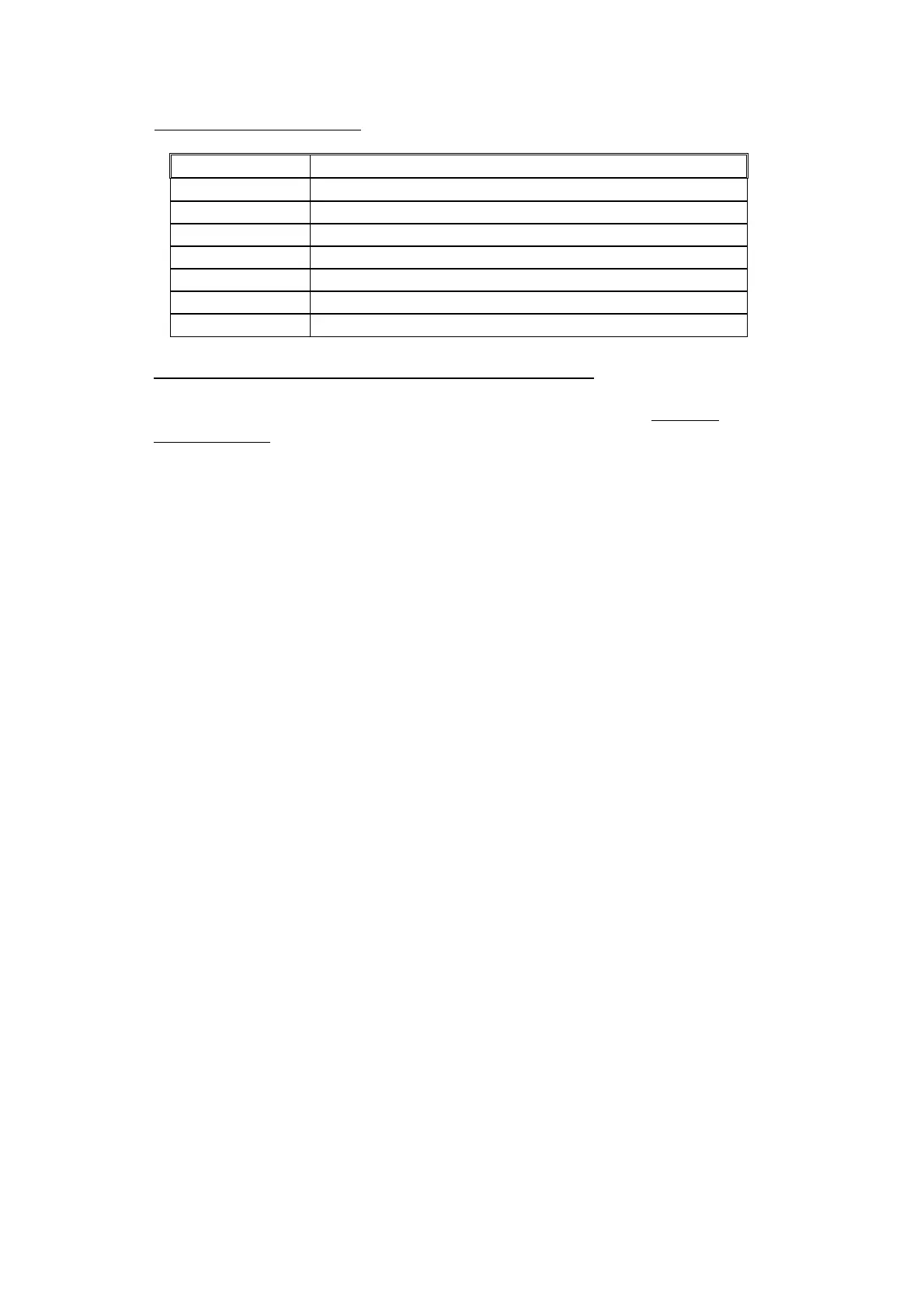

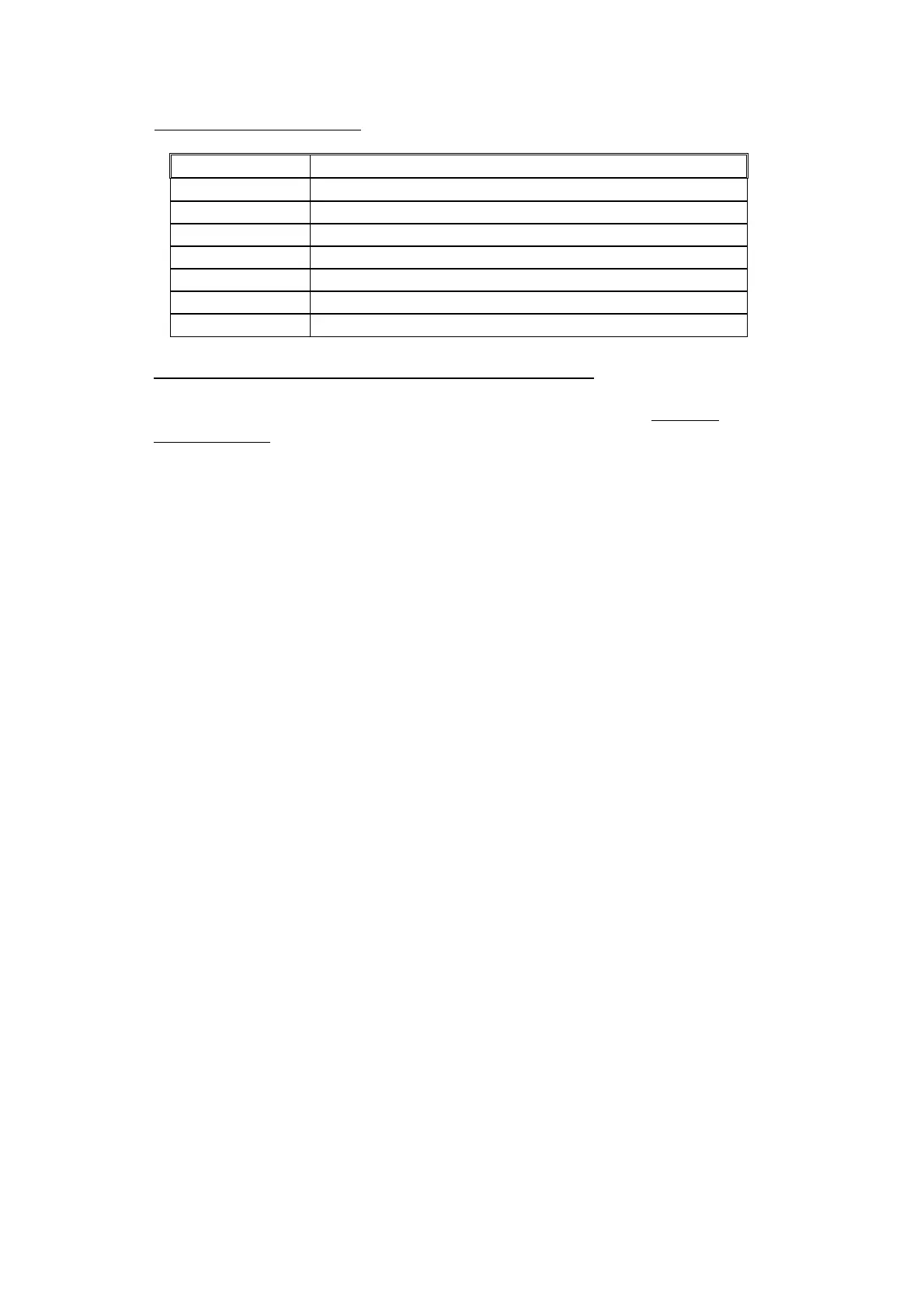

3. Variables #12001 ~ #13500

Variable Number Variable Data

12001 ~ 12002 Machine Coordinate (Current tool position) *

12021 ~ 12022 Program Coordinate (Current tool position) *

12201 ~ 12202 Machine Coordinate (Planned position) *

12221 ~ 12222 Program Coordinate (Planned position) *

12121 ~ 12122 Following Error

12141 ~ 12142 Unit for Machine Coordinate Resolution (Pulse)

12161 ~ 12162 Unit for Relative Machine Coordinate Resolution (Pulse)

* Viewing Machine Coordinate and Program Coordinate

When executing a program in AUTO mode, HUST controller will pre-fetch

program blocks (maximum 600 blocks) into buffer and do calculation. However,

some command codes, such as G31 and “G65 L50” ~ “G65 L56” will prevent the

controller from pre-fetching process. Due to this reason, the machine coordinate

and the program coordinate obtained from the variables will be different.

Following examples are attempted to explain this difference.

Ex 1:

Viewing the current tool position while executing the program below.

Machine coordinate – V#12001 ~ V#12002

Program coordinate – V#12021 ~ V#12022

N001 G01 X300.

N002 G11 P01

N003 X480.

N004 G65 L01 P#1 A#12021 – (Current program coordinate on X-axis)

N005 G01 X0.

N006 M02

When you start execution, the tool starts moving while the controller begins

pre-fetching process. At block N004, the controller execute “V#1 = V#12021”

(current tool position on X-axis) and the tool position at this moment may be at

1.052. If you try to view V#1 at this moment, it’ll read V#1=1052.

Ex 2:

Viewing the planned tool position while executing the program below.

Machine coordinate – V#12201 ~ V#12202

Program coordinate – V#12221 ~ V#12222

N001 G01 X300.

N002 G11 P01

N003 X480.

N004 G65 L01 P#1 A#12221 – (Planned program coordinate on X-axis)

N005 G01 X0.

N006 M02

Loading...

Loading...