Maintenance and RepaiR

powermax

45

Operator Manual 5-5

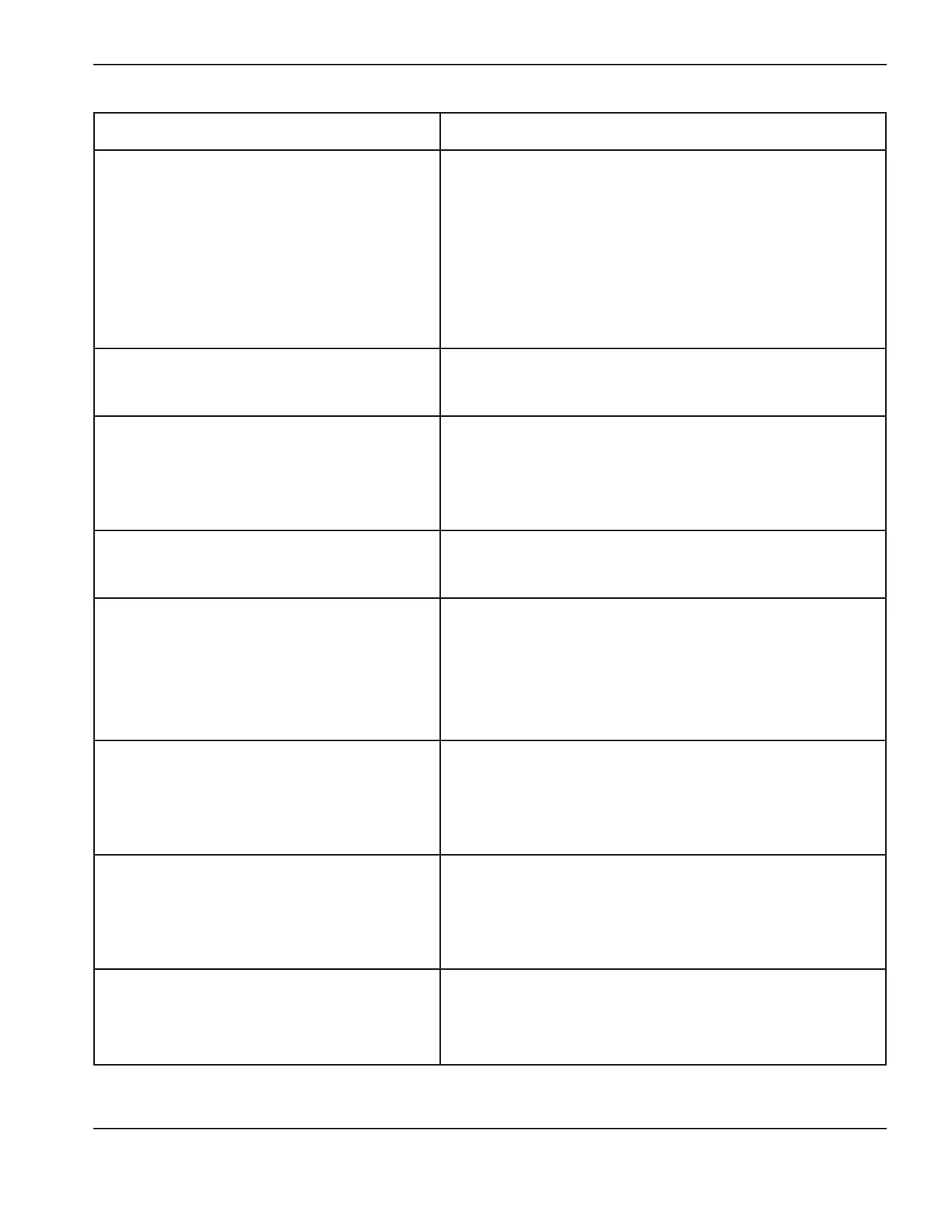

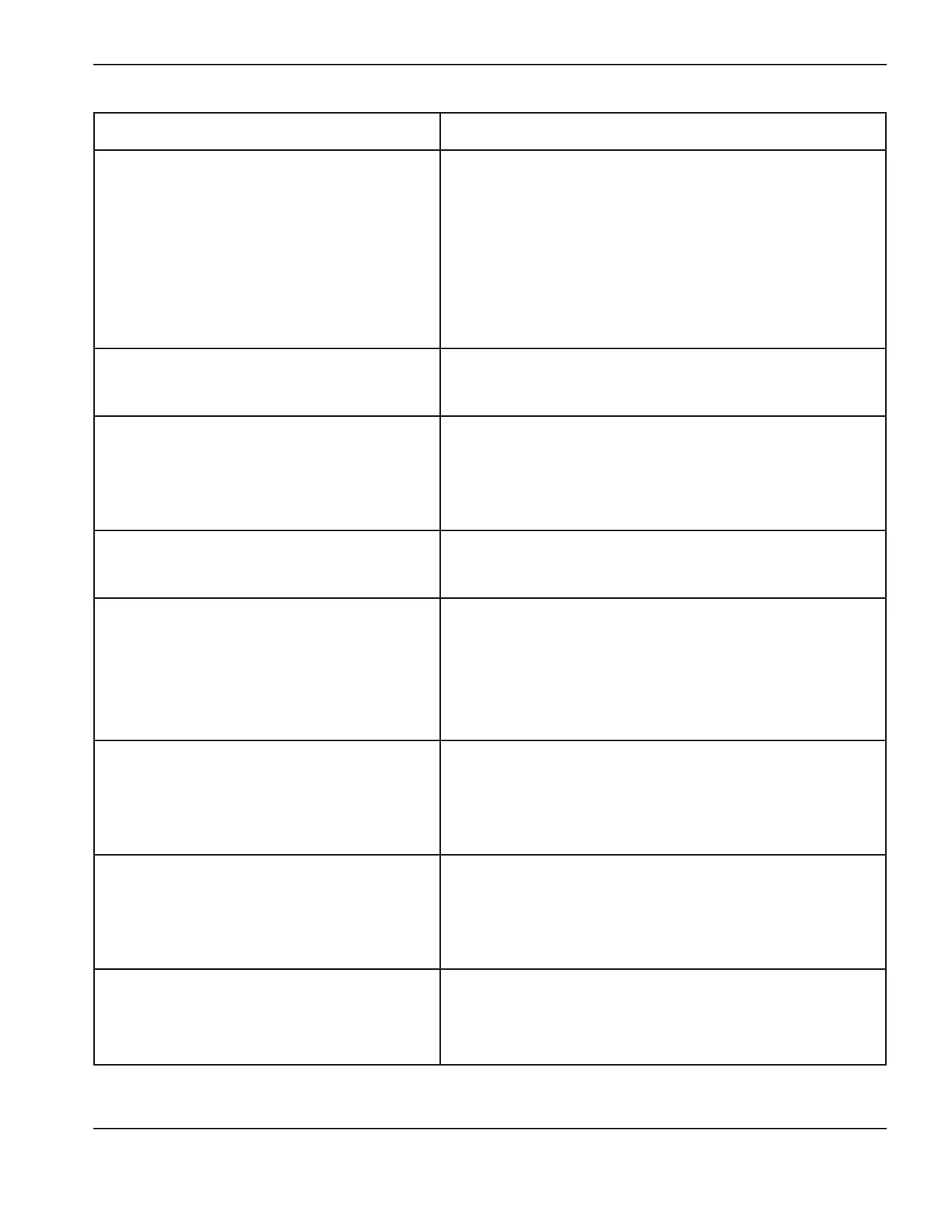

Problem Solutions

The power ON LED is illuminated and the torch

cap LED blinks.

This indicates either a “torch stuck open” or a “torch stuck

closed” situation.

• If the consumables became loose or were removed while the

power supply is ON, turn OFF the power supply, correct the

problem and then turn ON the power supply to clear this fault.

See Install the consumables in the Torch Setup section.

• If the consumables appear to be installed correctly, the torch

may be damaged. Contact your Hypertherm distributor or

authorized repair facility.

The fault LED blinks. • A blinking fault LED indicates a major fault with the system. A

qualified service technician must service the system. Contact

your distributor or authorized repair facility.

The gas pressure bar’s LED and the temperature

LED alternately blink when the system is turned

on.

This situation indicates that the power supply is receiving a start

signal. It is sometimes referred to as a “stuck start.”

• If the power supply is turned on while the torch trigger is

pressed, the system will be disabled. Release the trigger and

restart the power supply.

The gas pressure bar’s LED illuminates yellow at

the bottom of the gauge, and blinks.

• Inlet gas supply pressure is lower than the minimum

acceptable level. The LED continues to blink for 10 seconds

after the gas pressure is restored to the acceptable range.

The arc does not transfer to the workpiece. • Clean the area where the work clamp contacts the workpiece,

to ensure a good metal-to-metal connection.

• Inspect the work clamp for damage, and repair itif necessary.

• The torch-to-work distance may be too large. Move the torch

closer to the workpiece and fire the torch again. See the

Operation section.

The arc blows out, but re-ignites when the torch

trigger is pressed again.

• Inspect the consumable parts and replace them if they are

worn or damaged. See Inspect the consumables on page

5-3.

• Replace the gas lter element if it is contaminated. See

Replace the gas filter element on page 5-8.

The arc sputters and hisses. • The gas lter element is contaminated. Replace the element.

See Replace the gas filter element on page 5-8.

• Inspect the gas line for moisture. If necessary, install or repair

the gas filtration to the power supply. See Prepare the gas

supply in the Power Supply Setup section.

The cut quality is poor. • Verify that the torch is being used correctly. See the Operation

section.

• Inspect the consumables for wear and replace as necessary.

See Inspect the consumables on page 5-3.

Loading...

Loading...