12 © 2012 Installation and Reference Manual D0125 Rev. H

Section 2 — Installation

6. Electrical Power Connection

This operator is intended for permanent installation.

All electrical conduits must be properly connected to

the control box. The entry for the primary power is a

½ - ¾-inch knockout on the left side of the control box

next to the power switch. The operator is built to run

on a specific voltage and phase. Make sure you have

compared the available line voltage and phase with

the voltage and phase listed on the nameplate on the

machine. They must match! Be certain that the

branch circuit wire size versus the distance of the run

from the main panel is large enough to avoid excess

voltage drop. At a minimum, a 20A circuit (protected

with a 20A Inverse Time Breaker) should be provided.

Also be sure the operator is electrically grounded per

NEC Article 250 and local codes. See page 59 for

correct wire sizes and detailed electrical wiring

information.

7. Primary Tap of Control Transformer

Check to make sure that the primary tap on the control

transformer matches the line voltage you have

connected to the operator. Measure the line voltage

carefully to distinguish between 208V and 230V

branch circuits or between 390V and 460V branch

circuits. A label on top of the transformer identifies the

various voltage taps. This connection must match the

voltage on the operator nameplate.

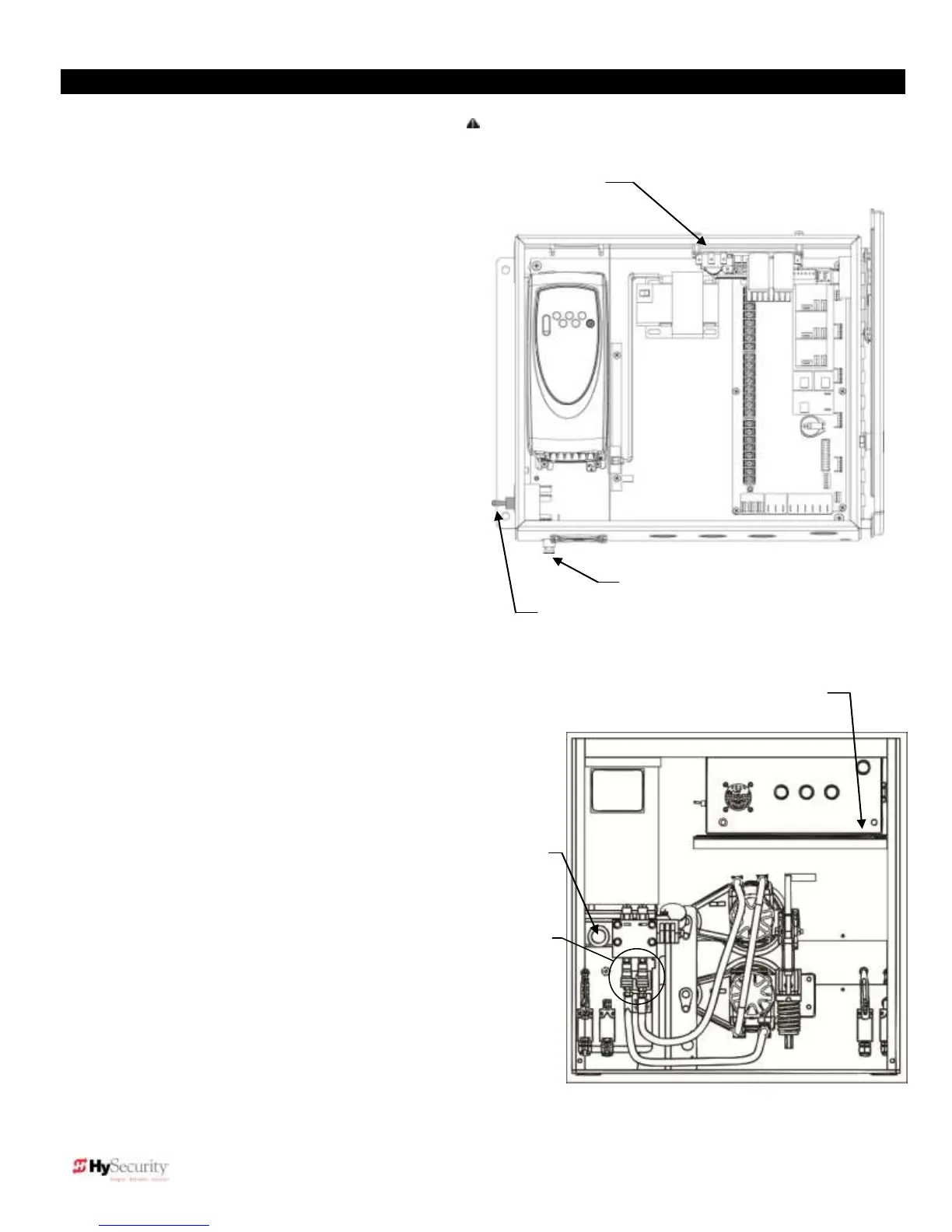

8. Check the operator “Hand”

All slide operators must have their “handing” set

before they can function. The “handing” must be

set both by the proper hydraulic hose connection

and by programming the Smart Touch Controller.

The proper handing hose connection is described

on a label near the hose connection point. Also,

see the instructions to set handing on page 19.

Operators are shipped configured for right hand

operation. Handing is viewed by standing on the

secure side looking out. A gate which opens to the

right is a right-handed gate.

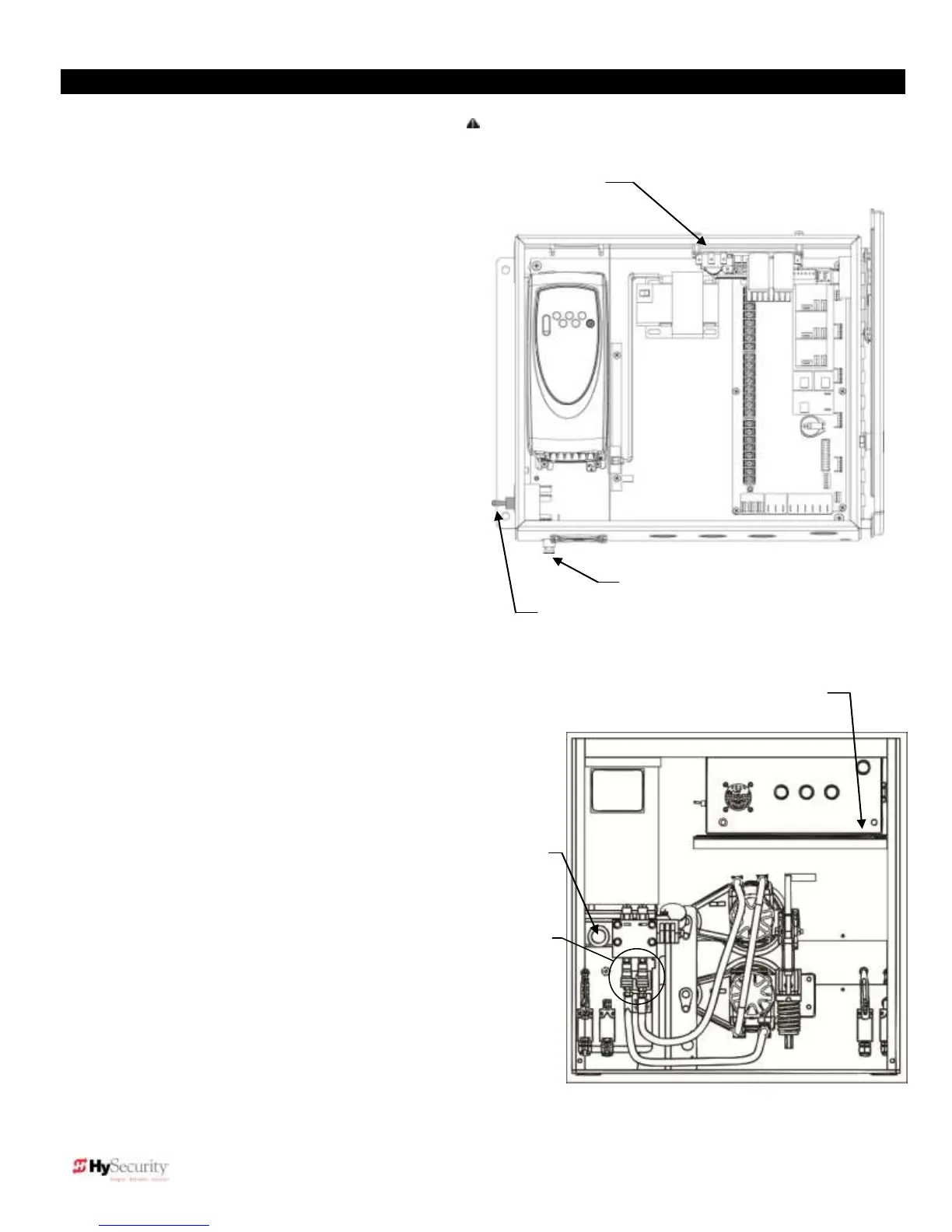

9. Replace the Shipping Plug!

Replace the ½″ steel or red plastic shipping plug

on the front side of the pump with the black

breather cap.

10. Setup the Smart Touch Controller

The operator controls will not allow the gate to function

until the Smart Touch Controller has been configured.

Wait to connect external controls until you have

reviewed Smart Touch Controller instructions and tested

operator basic functions.

CAUTION:

Variable frequency (VF) operators:

Make sure the connecting wires match the voltage

found on the operator’s nameplate. NEVER connect to

the white – 120V wire.

“Right Hand” shown

Remove red plastic

shipping plug and

replace with black

breather cap.

To change handing

connect hoses

according to label on

tank.

Loading...

Loading...