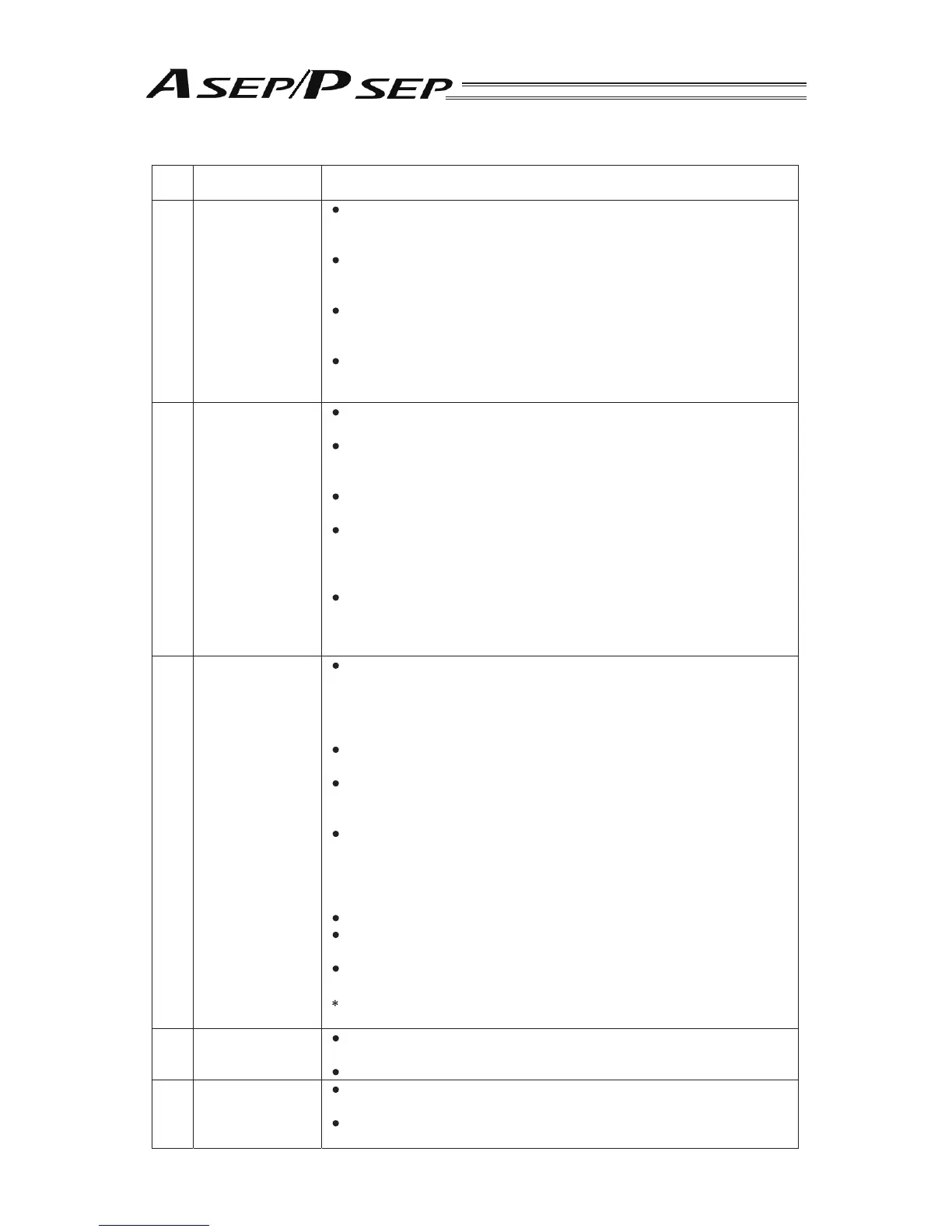

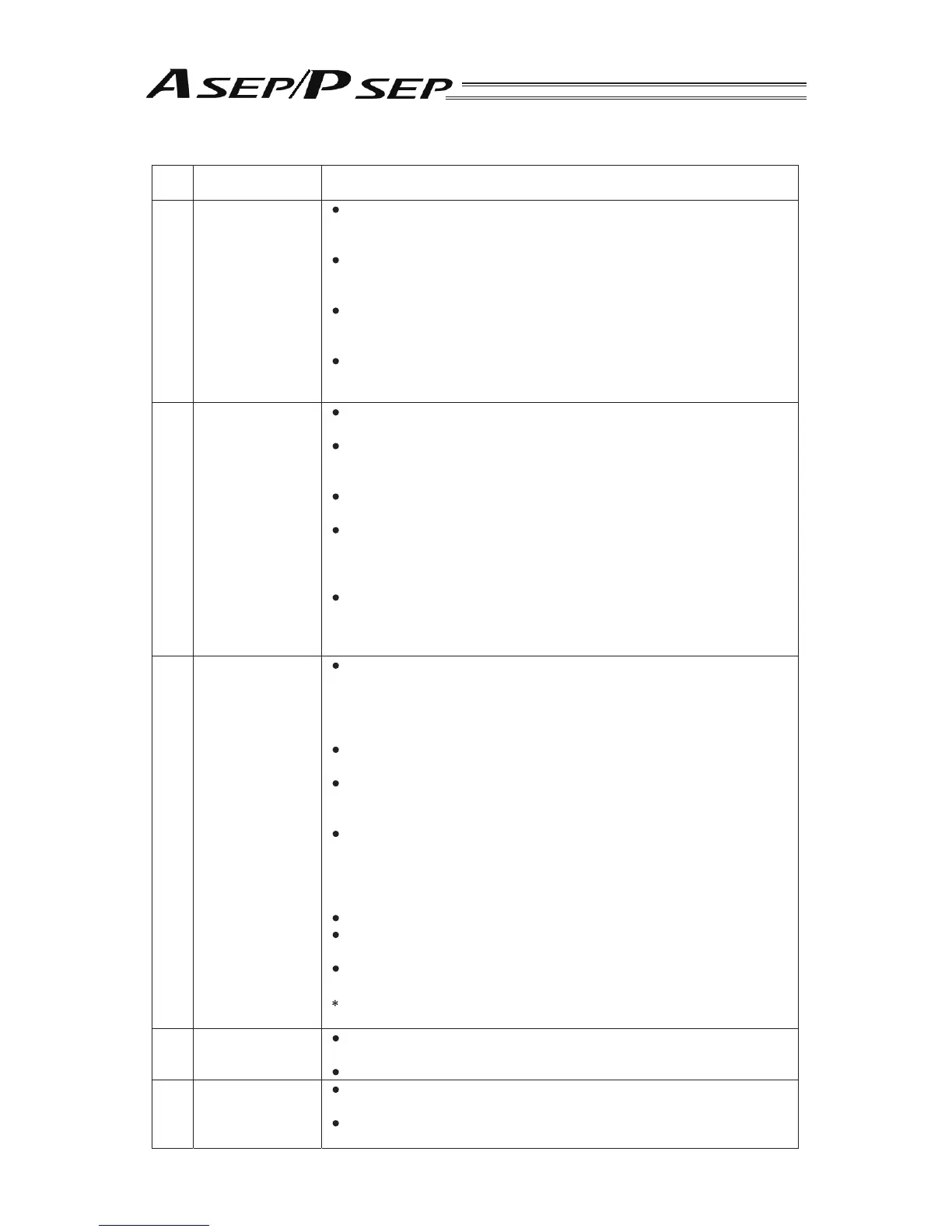

7

No.

Operation

Description

Precautions

6 Check Operation After the teaching or programming operation, perform the check

operation one step by one step and then shift to the automatic

operation.

When the check operation is to be performed inside the safety

protective fence, perform the check operation using the previously

specified work procedure like the teaching operation.

Make sure to perform the programmed operation check at the safety

speed. Failure to do so may result in an accident due to unexpected

motion caused by a program error, etc.

Do not touch the terminal block or any of the various setting switches

in the power ON mode. Failure to do so may result in an electric

shock or malfunction.

7 Automatic

Operation

Before the automatic operation is started up, make sure that there is

nobody inside the safety protective fence.

Before the automatic operation is started up, make sure that all the

related peripheral machines are ready for the automatic operation

and there is no error indication.

Make sure to perform the startup operation for the automatic

operation, out of the safety protective fence.

In the case that there is any abnormal heating, smoke, offensive

smell, or abnormal noise in the product, immediately stop the

machine and turn OFF the power switch. Failure to do so may result

in a fire or damage to the product.

When a power failure occurs, turn OFF the power switch. Failure to

do so may cause an injury or damage to the product, due to a sudden

motion of the product in the recovery operation from the power

failure.

8 Maintenance/

Inspection

Perform the work out of the safety protective fence, if possible. In the

case that the operation is to be performed unavoidably inside the

safety protective fence, prepare the “Stipulations for the Operation”

and make sure that all the workers acknowledge and understand

them well.

When the work is to be performed inside the safety protective fence,

basically turn OFF the power switch.

When the operation is to be performed inside the safety protective

fence, the worker should have an emergency stop switch at hand

with him so that the unit can be stopped any time in an emergency.

When the operation is to be performed inside the safety protective

fence, in addition to the workers, arrange a watchman so that the

machine can be stopped any time in an emergency. Also, keep watch

on the operation so that any third person can not operate the

switches carelessly.

Place a sign “Under Operation” at the position easy to see.

For the grease for the guide or ball screw, use appropriate grease

according to the Instruction Manual for each model.

Do not perform the dielectric strength test. Failure to do so may result

in a damage to the product.

Safety Protective Fence : In the case that there is no safety protective

fence, the movable range should be indicated.

9 Modification

Do not modify, disassemble, assemble or use of maintenance parts

not specified based at your own discretion.

In such case, the warranty is not applied.

10 Disposal

When the product becomes no longer usable or necessary, dispose

of it properly as an industrial waste.

Do not put the product in a fire when disposing of it.

The product may burst or generate toxic gases.

Loading...

Loading...