MECHANICAL

AND

ELECTRICAL

PRINCIPLES

THE

REAR cover assembly and the covers on the right

and left ends of the machine are each held in place

by

means of concealed latches. These latches may

be

released

by

pressing on the latch cover plate.

The cover over the switch plate

is

hinged at the

bottom and held in place

by

a holding screw at the

upper right hand corner. The right end cover must

be removed before this holding screw

is

accessible.

Four adjustable levelers are furnished with each

machine for the purpose of leveling the machine and

to eliminate excessive vibration caused

by

an uneven

floor surface.

Chute Blades

and

Sort

Magnet

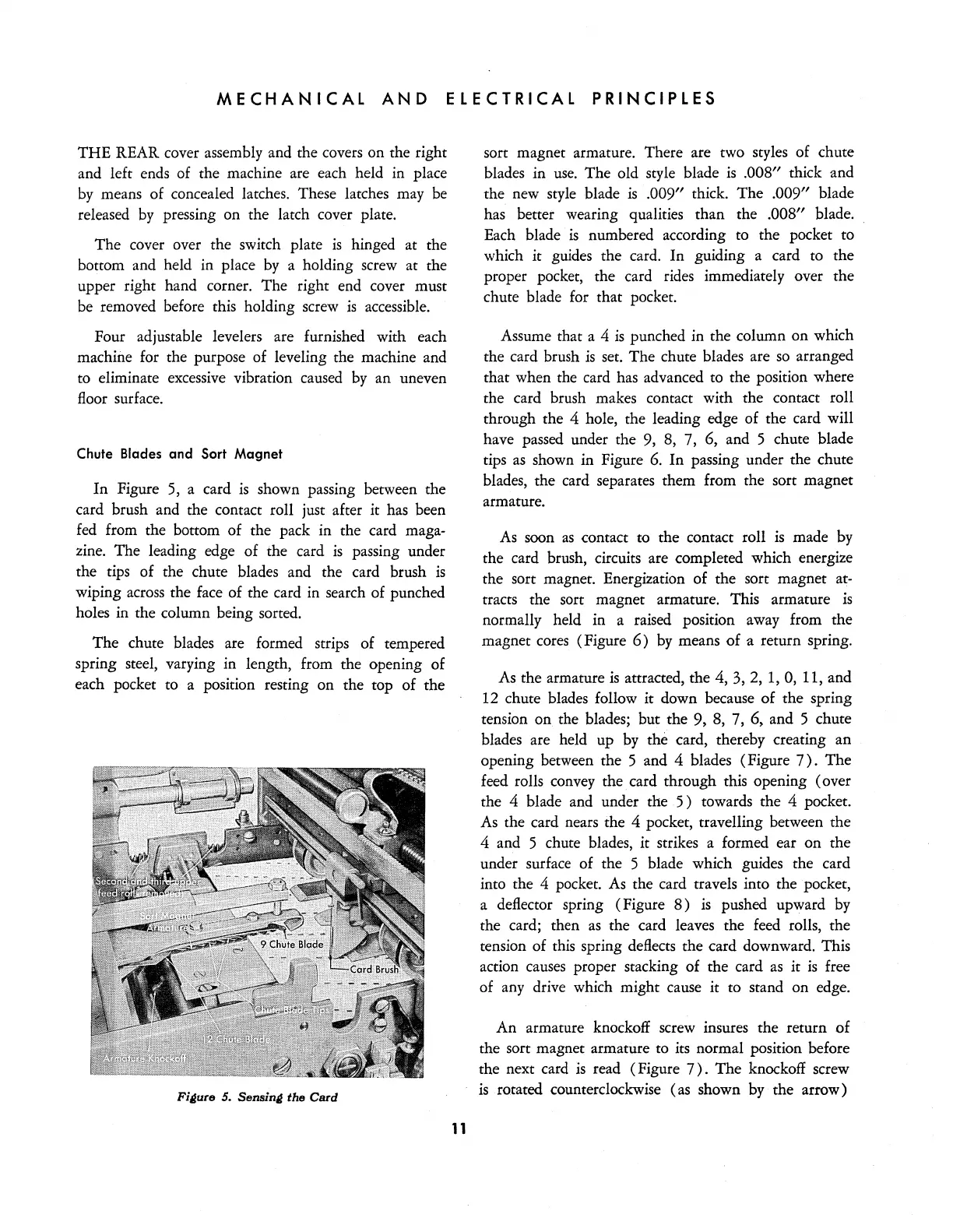

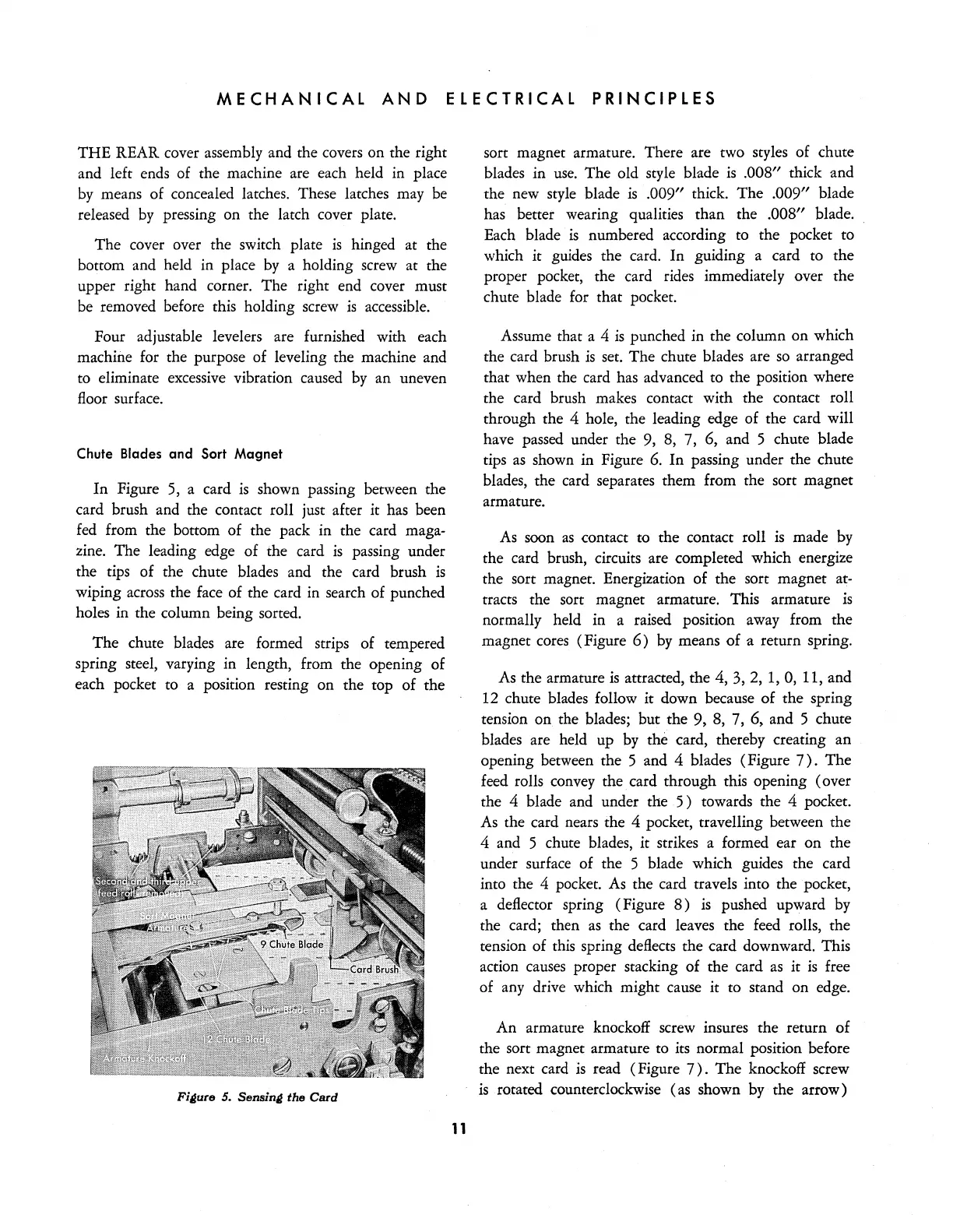

In

Figure 5, a card

is

shown passing between the

card brush and the contact roll just after it has been

fed

from the bottom of the pack in the card maga-

zine. The leading edge of the card

is

passing under

the tips of the chute blades and the card brush

is

wiping across the face of the card in search of punched

holes in the column being sorted.

The

chute blades are formed strips of tempered

spring steel, varying in length, from the opening of

each pocket to a position resting on the top of the

Fi~ure

5.

Sensin~

the

Card

11

sort magnet armature. There are two styles of chute

blades in

use.

The old style blade

is

.008" thick and

the new style blade

is

.009" thick. The .009" blade

has better wearing qualities than the

.008" blade.

Each blade

is

numbered according to the pocket to

which it guides the card.

In

guiding a card to the

proper pocket, the card rides immediately over the

chute blade for that pocket.

Assume that a 4

is

punched in the column on which

the card brush

is

set. The chute blades are

so

arranged

that when the card has advanced to the position where

the card brush makes contact with the contact roll

through the 4 hole, the leading edge of the card will

have passed under the 9, 8, 7, 6, and 5 chute blade

tips

as

shown in Figure

6.

In

passing under the chute

blades, the card separates them from the sort magnet

armature.

As

soon

as

contact

to

the contact roll

is

made

by

the card brush, circuits are completed which energize

the sort magnet. Energization of the sort magnet at-

tracts the sort magnet armature. This armature

is

normally held in a raised position away from the

magnet cores (Figure

6)

by

means

of

a return spring.

As the armature

is

attracted, the 4,

3,2,

1,

0,

11, and

12 chute blades follow it down because of the spring

tension

on

the blades; but the 9, 8, 7, 6, and 5 chute

blades are held up by the card, thereby creating an

opening between the 5 and 4 blades (Figure

7).

The

feed rolls convey the card through this opening (over

the 4 blade and under the

5)

towards the 4 pocket.

As

the card nears the 4 pocket, travelling between the

4 and 5 chute blades, it strikes a formed ear on the

under surface of the 5 blade which guides the card

into the 4 pocket.

As

the card travels into the pocket,

a deflector spring (Figure

8)

is

pushed upward by

the card; then

as

the card leaves the feed rolls, the

tension of this spring deflects the card downward. This

action causes proper stacking of the card

as

it

is

free

of any drive which might cause it to stand on edge.

An armature knockoff screw insures the return of

the sort magnet armature to its normal position before

the next card

is

read (Figure

7).

The

knockoff screw

is

rotated counterclockwise (as shown by the arrow)

Loading...

Loading...