18

CARD

SORTING

MACHINE,

TYPE

82

reverse lock

is

in the form of a ratchet knurl cut on the

rim of the drive pulley. A locking pawl operates against

the pulley when the force of motion

is

in a clockwise

direction (viewed from the pulley

end),

thus preventing

any actual rotation of the pulley.

When

the direction of

rotation

is

counterclockwise (viewed from the pulley

end),

the locking pawl

is

held away from the knurled

edge through the action of the pawl operating arm.

The pawl operating arm

is

actuated

by

a friction contact

with the drive pulley. The knurled teeth on the rim

of

the pulley are fine enough to prevent any appre-

ciable motion when the reverse lock operates. Any older

Type

80 machines which are not equipped with the

declutching type of handwheel should have a reverse

lock mechanism.

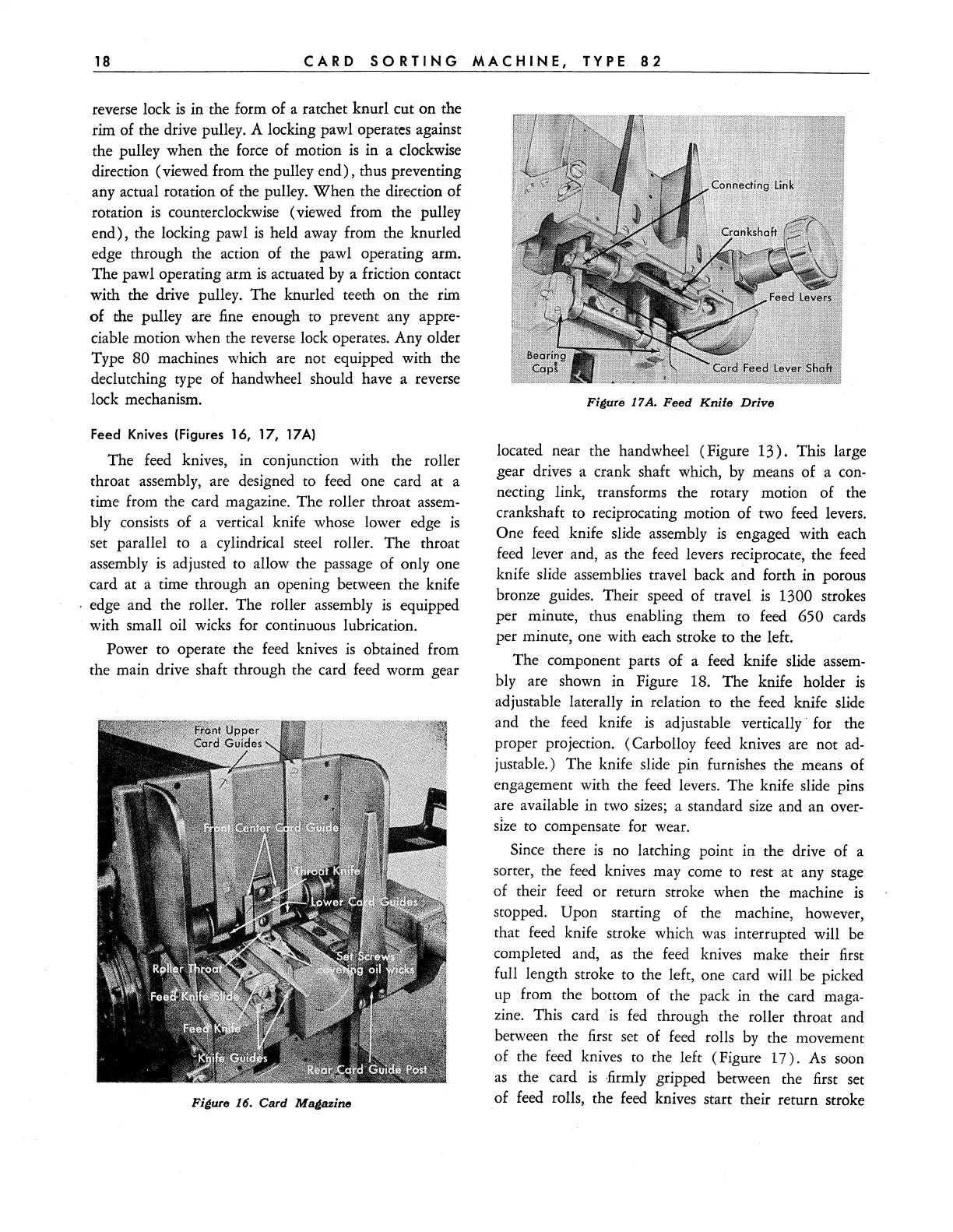

Feed

Knives

(Figures 16, 17, 17A)

The

feed

knives, in conjunction with the roller

throat assembly, are designed to feed one card at a

time from the card magazine. The roller throat

assem-

bly consists of a vertical knife whose lower edge

is

set parallel

to

a cylindrical steel roller. The throat

assembly

is

adjusted to allow the passage of only one

card at a time through an opening between the knife

. edge and the roller. The roller assembly

is

equipped

with small oil wicks for continuous lubrication.

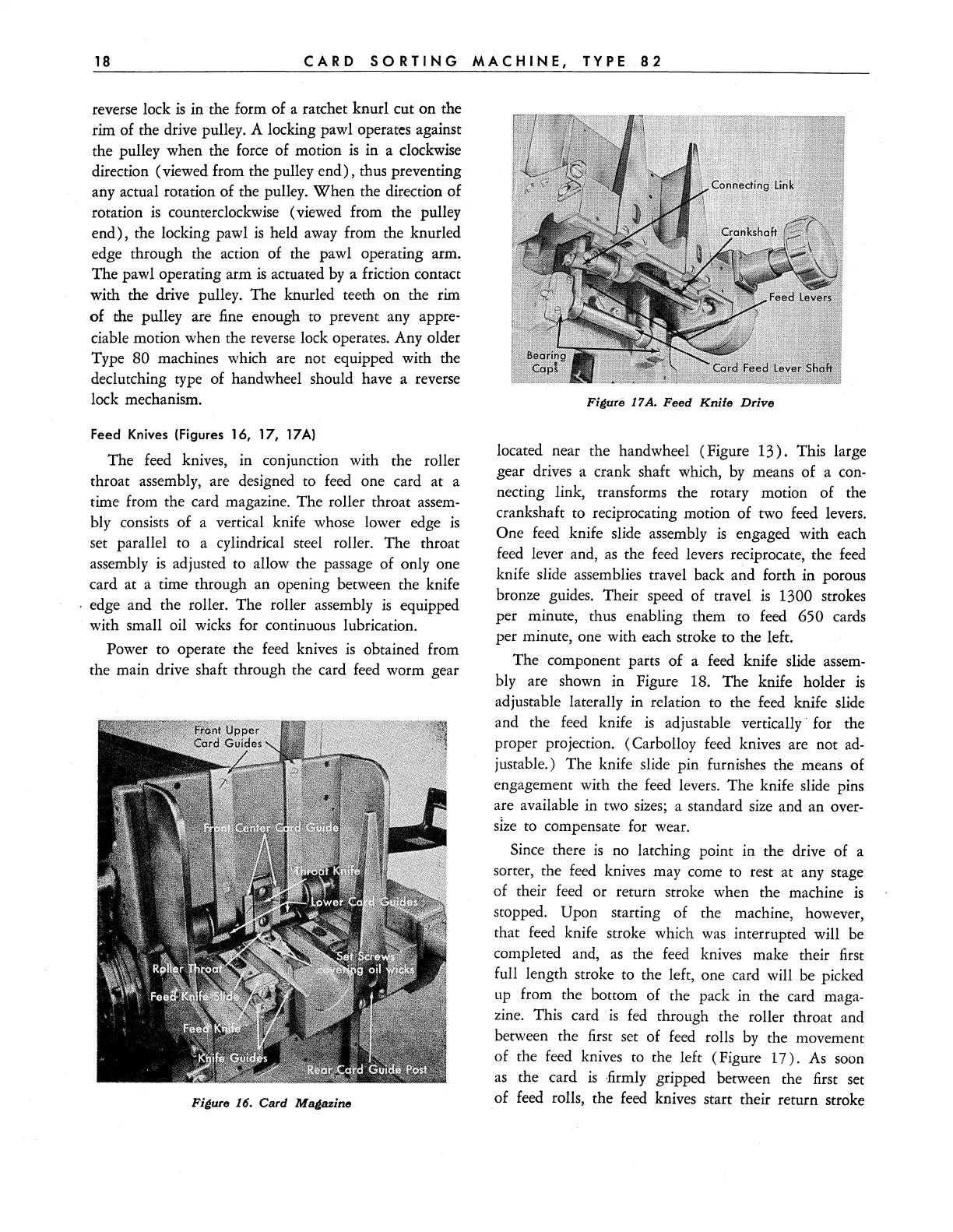

Power to operate the

feed

knives

is

obtained from

the main drive shaft through the card

feed

worm gear

Figure

16.

Card

Magazine

Figure

17A.

Feed

Knife

Drive

located near the handwheel (Figure

13).

This large

gear drives a crank shaft which,

by

means of a con-

necting link, transforms the rotary motion of the

crankshaft to reciprocating motion of two feed levers.

One feed knife slide assembly

is

engaged with each

feed

lever and,

as

the

feed

levers reciprocate, the

feed

knife slide assemblies travel back and forth in porous

bronze guides. Their speed of travel

is

1300 strokes

per minute, thus enabling them to feed

650 cards

per minute, one with each stroke to the left.

The component parts of

a feed knife slide

assem-

bly are shown in Figure 18. The knife holder

is

adjustable laterally in relation to the feed knife slide

and the

feed

knife

is

adjustable vertically' for the

proper projection. (Carbolloy

feed

knives are not

ad-

justable.) The knife slide pin furnishes the means of

engagement with the feed levers. The knife slide pins

are available in two

sizes;

a standard

size

and an over-

SIze

to

compensate for wear.

Since there

is

no latching point in the drive of a

sorter, the

feed

knives may come to rest at any stage

of their

feed

or return stroke when the machine

is

stopped. Upon starting of the machine, however,

that

feed

knife stroke which

was

interrupted will

be

completed and,

as

the

feed

knives make their first

full length stroke to the left, one card will be picked

up

from the bottom of the pack in the card maga-

zine. This card

is

fed

through the roller throat and

between the first set of

feed

rolls

by

the movement

of the feed knives to the left (Figure

17).

As

soon

as

the card

is

·firmly

gripped between the first set

of

feed

rolls, the

feed

knives start their return stroke

Loading...

Loading...