CARD

MATCHING

DEVICE

57

the advent of a detail card which again causes sorting

into the 9 pocket. Thus, it can be seen that if two

master cards occur in direct succession, the first master

card will follow its group of detail cards into the 9

pocket while the second master card will

be

rejected.

As

long

as

each master card

is

preceded

by

one or more

detail cards, both the detail cards and their master

card will sort into the 9 pocket.

If

it

is

desired

to

match a group of detail cards with

more than one master card, the master card identifica-

tion must occur only in the last master card of each

group.

If

the identifying punch or corner cut were

to

occur in all master cards, the first master card of each

group would

tollow its detail cards into the 9 pocket

but the latter master cards of the

group would be

re-

jected.

Cards which have no punching or no corner cut

which can be read

by

either the card brush or the rail

brush will

SOrt

into the same pocket

as

the preceding

card.

If

such a card

is

the first card fed into the machine,

it will reject.

Those cards having a corner cut or significant punch-

ing which

is

read

by

the card brush will reject, unless

they are preceded

by

a detail card.

The arrangement of the cards

as

well

as

the identify-

iRg

punching or corner cuts in the cards

is

a factor

that governs matching. However, it should

be

remem-

bered that matching with this device should

be

done

only with a master deck that

is

known to

be

complete.

CIRCUIT DESCRIPTION

THE

FOLLOWING

circuit description for card matching

covers the operation of a Type 82 Sorter with a card

matching device. The circuits described refer to wiring

diagram

270094. A reproduction of this wiring dia-

gram

is

shown in Figure 41.

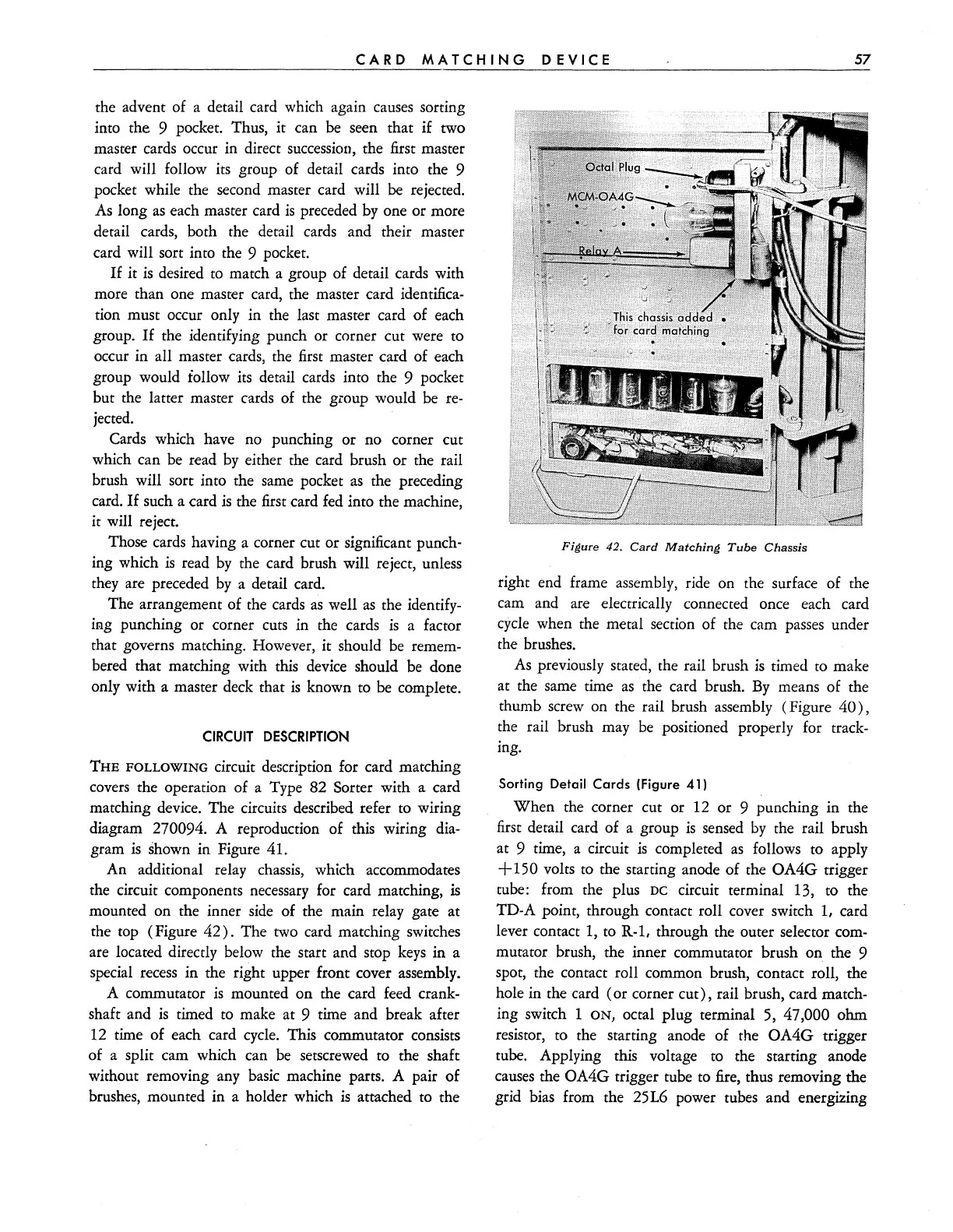

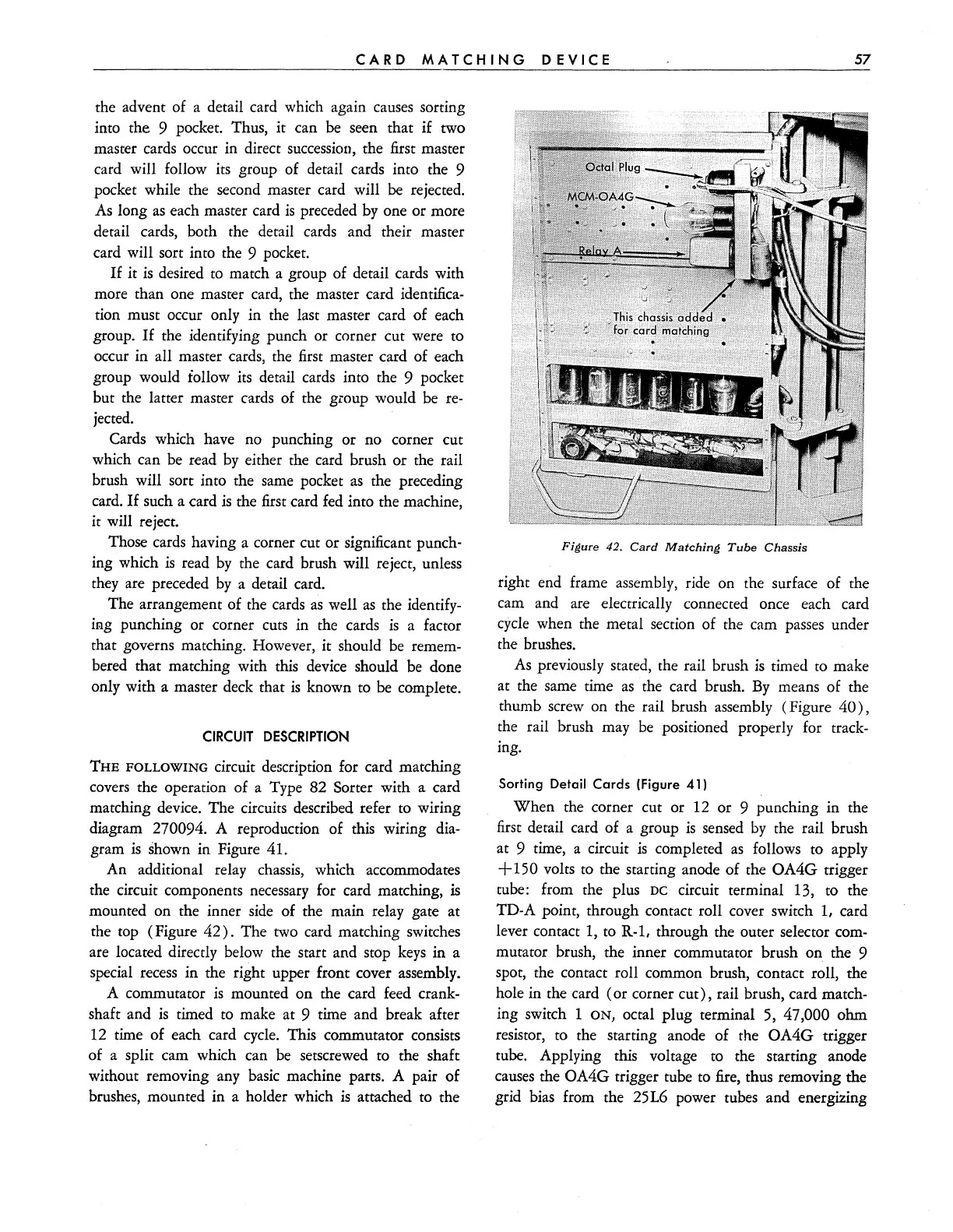

An additional relay chassis, which accommodates

the circuit components necessary for card matching,

is

mounted on the inner

side

of the main relay gate at

the top (Figure

42).

The two card matching switches

are located directly below the start and stop

keys

in a

special

recess

in the right upper front cover assembly.

A commutator

is

mounted on the card feed crank-

shaft and

is

timed

to

make at 9 time and break after

12 time of each card

cycle.

This commutator consists

of a split cam which can

be

setscrewed to the shaft

without removing any basic machine parts. A pair of

brushes, mounted in a holder which

is

attached to the

Figure

42.

Card

Matching

Tube

Chassis

right end frame assembly, ride on the surface of the

cam and are electrically connected once each card

cycle

when the metal section of the cam passes under

the brushes.

As

previously stated, the rail brush

is

timed

to

make

at the same time

as

the card brush.

By

means of the

thumb screw on the rail brush assembly (Figure

40),

the rail brush may

be

positioned properly for track-

ing.

Sorting

Detail

Cards

(Figure

41)

When the corner cut or 12 or 9 punching in the

first detail card of a group

is

sensed

by

the rail brush

at 9 time, a circuit

is

completed

as

follows to apply

+150

volts to the starting anode of the OA4G trigger

tube: from the plus

DC

circuit terminal 13, to the

TD-A point, through contact roll cover switch

1,

card

lever contact

1,

to

R-1,

through the outer selector com-

mutator brush, the inner commutator brush

on

the 9

spot, the contact roll common brush, contact roll, the

hole in the card (or corner

cut),

rail brush, card match-

ing switch

ION,

octal plug terminal

5,

47,000 ohm

resistor, to the starting anode of the

OA4G

trigger

tube. Applying

this voltage to the starting anode

causes

the OA4G trigger tube to

fire,

thus removing the

grid

bias from the 25L6 power tubes and energizing

Loading...

Loading...