M E C

HAN

I

CAL

AND

E L E C T R

IC

ALP

R

INC

I P L E S

21

in the reduction of any possible arcing

by

changing the

point of contact between the card brush and the contact

roll each card cycle.

The cutting effect of the card

is

more pronounced

at the first three feed roll stations than at any others.

For this reason, the rubber feed rolls at these stations

are equipped with metal flanges on either side of the

rubber rolls. These flanges serve to further prevent

knicking of the rubber rolls

by

deflecting the card

as

it strikes the roll. At the same time, because of

the position and diameter of the flanges, the rubber

portions of the rolls are permitted to exert pressure on

the card for feeding even though some wear has taken

place on the rubber rolls.

All feed roll gears are fastened to their

feed

roll

shafts

by

means of two setscrews through each gear

hub.

On recent machines, a hole

is

provided in the rear

magazine frame, permitting the entry of a setscrew

wrench to reach the setscrews in the first upper feed

roll gear.

Card

Levers

and Contacts (Figures 4, 19)

There are two card levers which operate

contact'S

to

govern machine circuits. Card lever 1 is located near

the

rear of the machine between the upper and lower

first

feed rolls and

is

operated

to

close

:its

contact just

as

the leading edge of the card enters the first feed rolIs.

Closing of card lever contact 1 allows the sorting

cir-

cuits

to

function if a hole

is

sensed in the card when it

passes under the card brush.

Card lever 2

is

located near the rear of the machine·

between the second and third upper feed rolls and

is

operated to close its contacts

as

the leading edge of the

card leaves the second feed roll. Closing of card lever

contact 2 governs two machine functions; one of which

is

to complete the circuits necessary for automatic

machine operation after the operator removes his finger

from the start

key.

The second function

is

to maintain

the sorting circuits during sorting of the last card in the

machine.

Once closed, the card lever contacts remain closed

during the time that cards are continuously feeding

through the machine, opening only when the machine

runs out of cards.

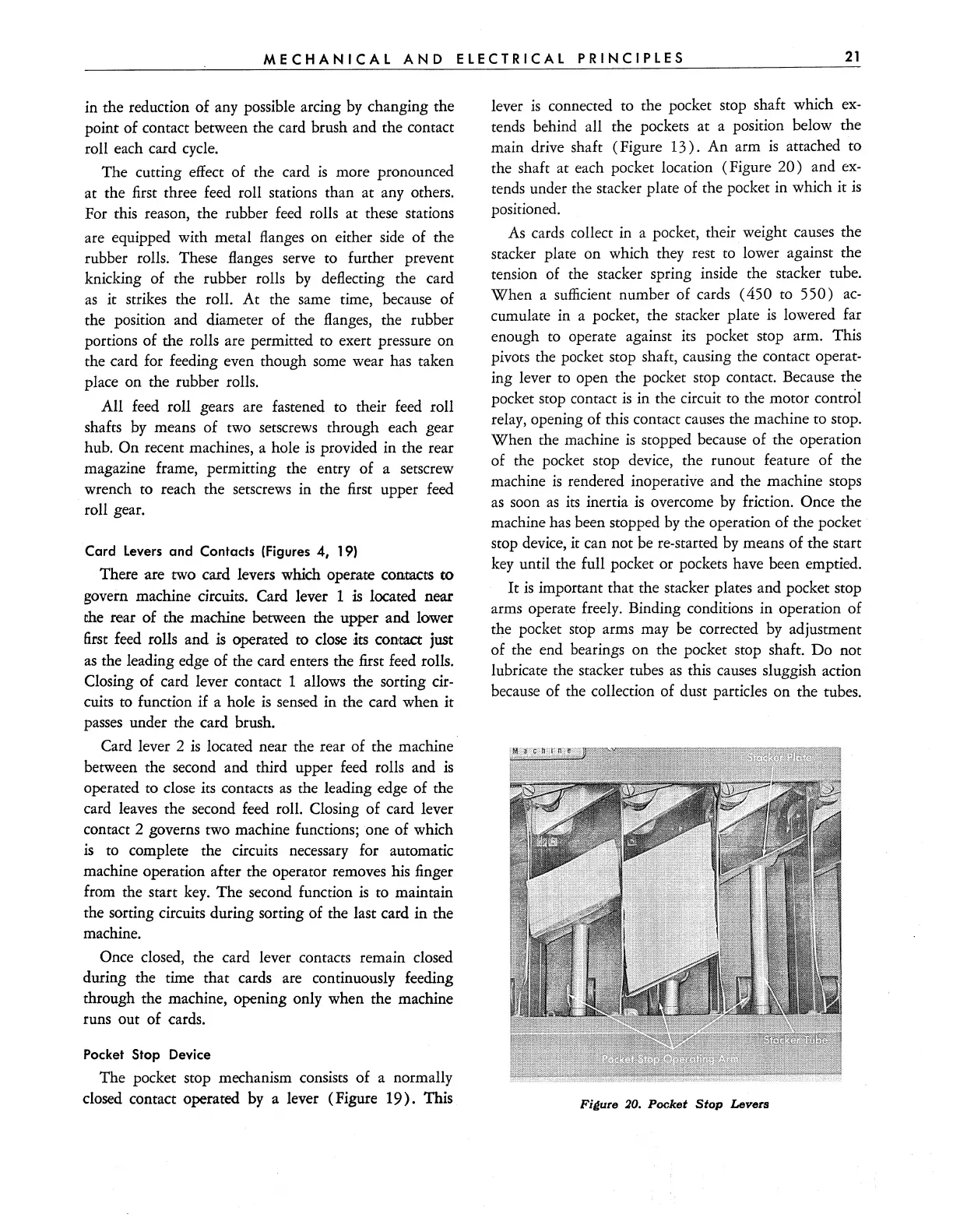

Pocket Stop Device

The pocket stop mechanism consists of a normally

closed contact operated

by

a lever (Figure

19).

This

lever

is

connected to the pocket stop shaft which

ex-

tends behind all the pockets at a position below the

main drive shaft (Figure

13).

An arm

is

attached

to

the shaft at each pocket location (Figure

20)

and

ex-

tends under the stacker plate of the pocket in which it

is

positioned.

As cards collect in a pocket, their weight causes the

stacker plate on which they rest to lower against the

tension of the stacker spring inside the stacker tube.

When

a sufficient number of cards (450 to

550)

ac-

cumulate in a pocket, the stacker plate

is

lowered far

enough to operate against its pocket stop arm. This

pivots the pocket stop shaft, causing the contact

operat-

ing lever to open the pocket stop contact. Because the

pocket stop contact

is

in the circuit to the motor control

relay, opening of this contact causes the machine to stop.

When the machine

is

stopped because of the operation

of the pocket stop device, the runout feature of the

machine

is

rendered inoperative and the machine stops

as

soon

as

its

inertia

is

overcome

by

friction. Once the

machine has been stopped

by

the operation of the pocket

stop device,

it

can not be re-started

by

means of the start

key until the full pocket or pockets have been emptied.

It

is

important that the stacker plates and pocket stop

arms operate freely. Binding conditions in operation of

the pocket stop arms may be corrected

by

adjustment

of the end bearings on the pocket stop shaft.

Do

not

lubricate the stacker tubes

as

this causes sluggish action

because of the collection of dust particles on the tubes.

Fi~ure

:10.

Pocket

Stop

Levers

Loading...

Loading...