20

CARD

SO

RTING

MACHINE,

TYPE

8-=2

_________

_

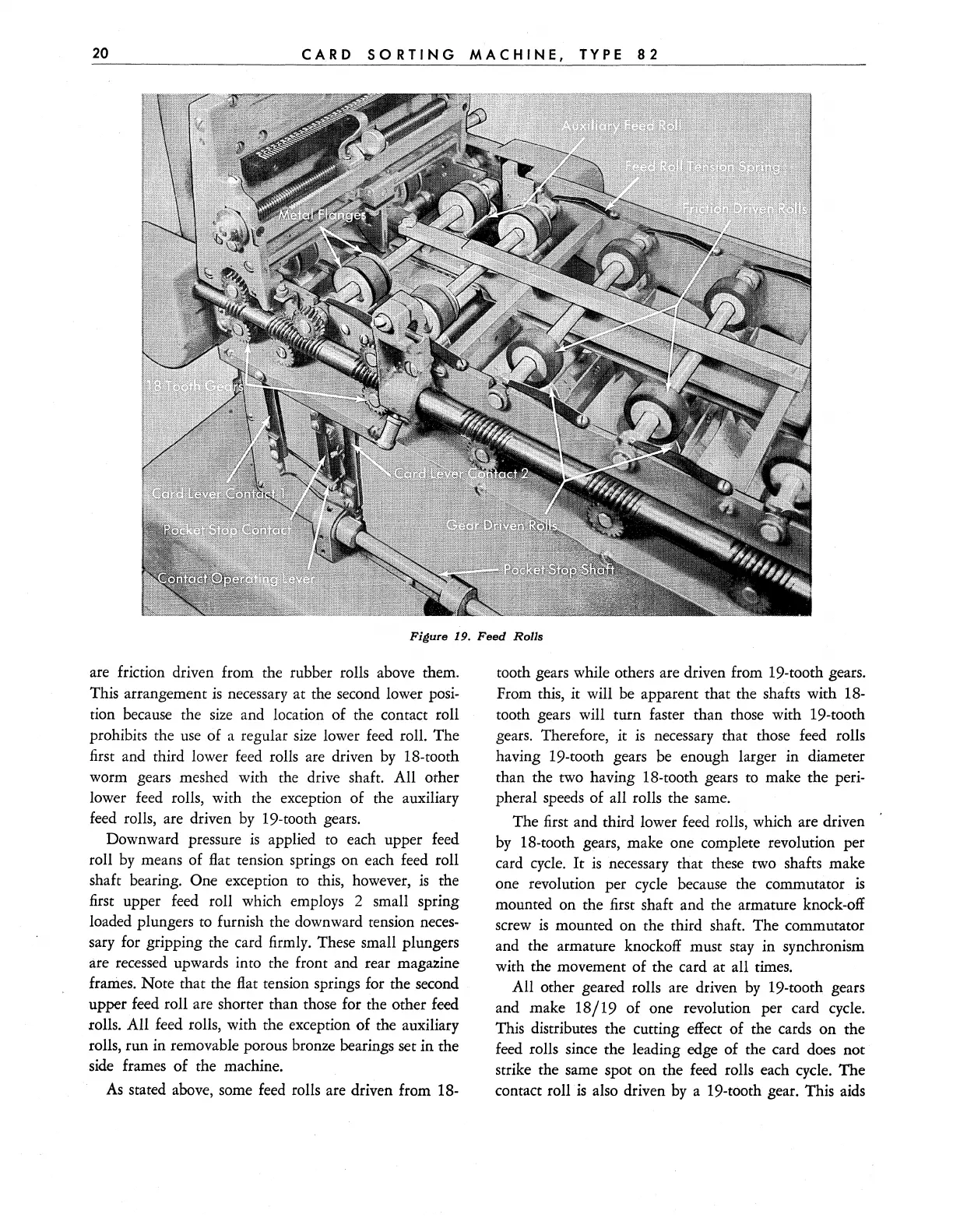

Figure

19.

Feed

RoIls

are friction driven from the rubber rolls above them.

This arrangement

is

necessary at the second lower posi-

tion because the

size

and location of the contact roll

prohibits the

use

of a regular

size

lower

feed

roll. The

first and third lower

feed

rolls are driven

by

18-tooth

worm gears meshed with the drive shaft. All other

lower feed rolls, with the exception of the auxiliary

feed

rolls, are driven

by

19-tooth gears.

Downward pressure

is

applied

to

each upper feed

roll

by

means of flat tension springs on each feed roll

shaft bearing.

One exception

to

this, however,

is

the

first upper feed roll which employs 2 small spring

loaded plungers

to

furnish the downward tension

neces-

sary for gripping the card firmly. These small plungers

are recessed upwards into the front and rear magazine

frames. Note that the flat tension springs for the second

upper feed roll are shorter than those for the other feed

rolls. All feed rolls, with the exception of the auxiliary

rolls, run in removable porous bronze bearings set in the

side frames of the machine.

As

stated above, some

feed

rolls are driven from 18-

tooth gears while others are driven from 19-tooth gears.

From this, it will be apparent that the shafts with 18-

tooth gears will turn faster than those with 19-tooth

gears. Therefore, it

is

necessary that those feed rolls

having 19-tooth gears be enough larger in diameter

than the two having 18-tooth gears to make the peri-

pheral speeds of all rolls the same.

The first and third lower feed rolls, which are driven

by

18-tooth gears, make one complete revolution per

card

cycle.

It

is

necessary that these two shafts make

one revolution per cycle because the commutator

is

mounted on the first shaft and the armature knock-off

screw

is

mounted on the third shaft. The commutator

and the armature knockoff must stay in synchronism

with the movement of the card at all times.

All other geared rolls are driven

by

19-tooth gears

and make

18/19

of one revolution per card cycle.

This distributes the cutting effect of the cards on the

feed rolls since the leading edge of the card does not

strike the same spot on the feed rolls each cycle. The

contact roll

is

also driven

by

a 19-tooth gear. This aids

Loading...

Loading...