MECHANICAL

AND

ELECTRICAL

PRINCIPLES

17

to the drive shaft

by

means of a V belt and pulleys.

Variations in machine speed are obtained

by

adjusting

the variable speed pulley on the drive motor. The

motor mounting

is

adjustable vertically and can be

pivoted in an arc for the purpose of regulating belt

tension and alignment. The complete motor and

mounting assembly

is

easily removed for repair or

renewal.

The drive shaft extends over the length of the

machine approximately on a level with the card line

(Figure

13).

Worms cut at intervals on the shaft

are used for the purpose of gearing to the

feed

roll

shafts, which run at right angles to the drive shaft.

Except for the first 3

sets

of feed rolls, only the lower

feed rolls are gear driven; the upper rolls are friction

driven from the lower rolls. Located at the right end

of the drive shaft (rear view)

is

a thrust bearing which

aids in absorbing the thrust developed in the shaft.

This bearing must be kept well lubricated.

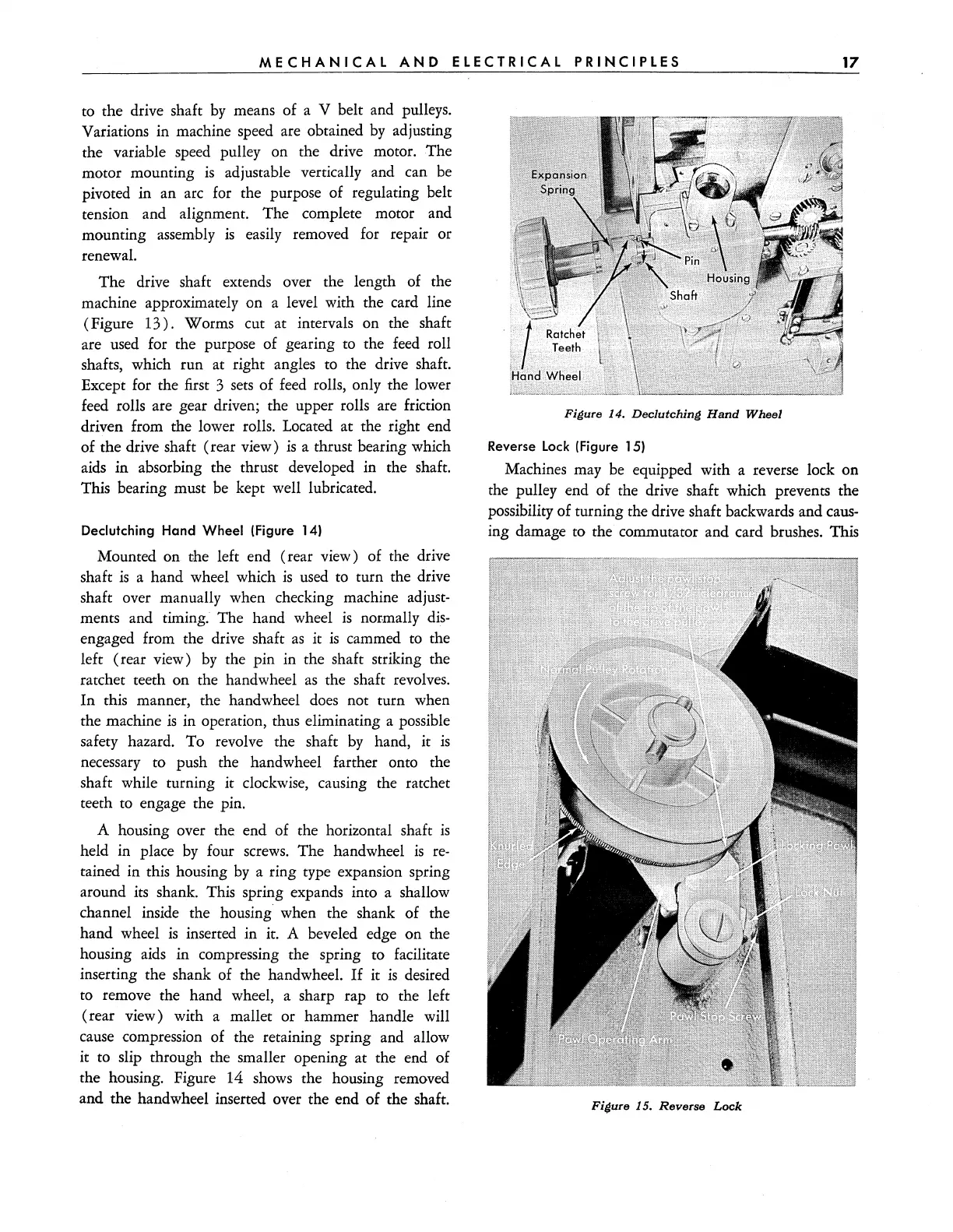

Declutching Hand Wheel (Figure 14)

Mounted on the left end (rear view) of the drive

shaft

is

a hand wheel which

is

used

to turn the drive

shaft over manually when checking machine adjust-

ments and timing. The hand wheel

is

normally

dis-

engaged from the drive shaft

as

it

is

cammed

to

the

left (rear view)

by

the pin in the shaft striking the

ratchet teeth on the handwheel

as

the shaft revolves.

In

this manner, the handwheel

does

not turn when

the machine

is

in operation, thus eliminating a possible

safety hazard. To revolve the shaft

by

hand, it

is

necessary to push the handwheel farther onto the

shaft while turning it clockwise, causing the ratchet

teeth to engage the pin.

A housing over the end of the horizontal shaft

is

held in place

by

four

screws.

The handwheel

is

re-

tained in this housing

by

a ring type expansion spring

around its shank. This spring expands into a shallow

channel inside the housing when the shank of the

hand wheel

is

inserted in it. A beveled edge on the

housing

aids

in compressing the spring to facilitate

inserting the shank of the handwheel.

If

it

is

desired

to remove the hand wheel, a sharp rap to the left

(rear view) with a mallet or hammer handle will

cause compression of the retaining spring and allow

it to slip through the smaller opening at the end of

the housing. Figure 14 shows the housing removed

and the handwheel inserted over the end

of

the shaft.

Figure 14.

Declutching

Hand

Wheel

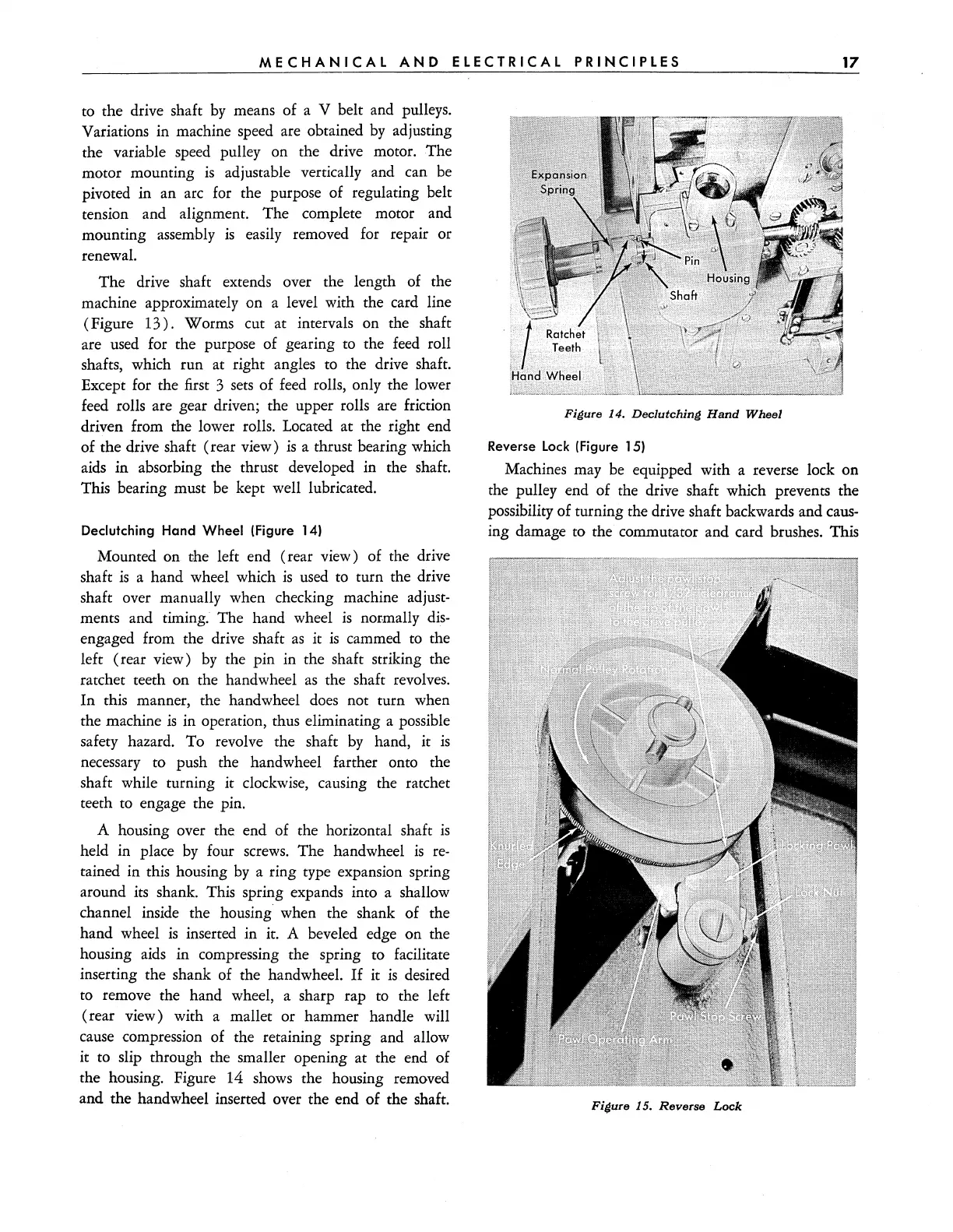

Reverse Lock (Figure 15)

Machines may be equipped with a reverse lock on

the pulley end of the drive shaft which prevents the

possibility of turning the drive shaft backwards and

caus-

ing damage to the commutator and card brushes. This

Figure 15.

Reverse

Lock

Loading...

Loading...