20

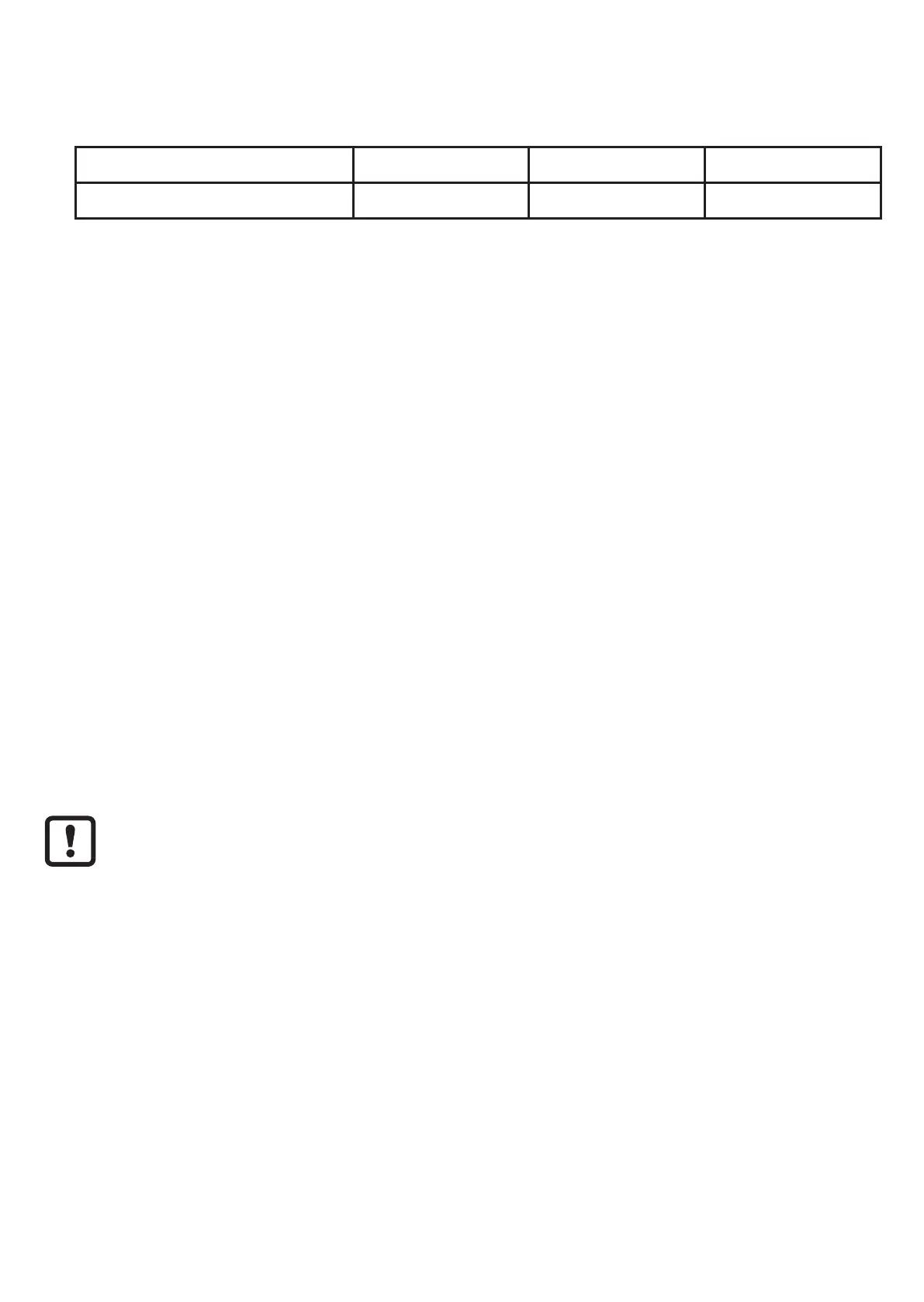

Arrange for a bore hole in the tank lid� It must have a minimum diameter (d) to ►

enable sufficient transfer of the measured signal to the probe� The diameter

depends on the wall thickness of the tank lid:

Wall thickness [mm] 1���5 5���8 8���11

Bore hole diameter [mm] 35 45 55

Install the flange plate with the flat surface showing to the tank and fix it with ►

appropriate screws�

A seal (B) can be inserted between flange plate and tank (some flange plates

are supplied with seal)�

Ensure cleanness and evenness of the sealing areas, especially if the tank is ►

under pressure� Tighten the fixing screws sufficiently�

Screw the unit in the flange plate and tighten firmly� ►

Make sure that the supplied sensor seal (A) is correctly positioned� ►

Installation of the unit with coaxial probe in the tank6.5

Seal the process connection� ►

For pipes with G¾ process connection: slide the supplied seal onto the thread •

of the coaxial pipe�

For pipes with G¾“ NPT process connection: apply a suitable sealing material •

(e�g� Teflon tape)�

Screw the sensor with the coaxial pipe into the tank and tighten it� ►

After installation, the sensor housing can be aligned� It can be rotated

without restriction� Even if rotated several times there is no risk of damage

to the unit�

Loading...

Loading...