Selection of Options

‑105‑

Pr = (U × U × D)/(R × K)

The braking resistor power is calculated accordingly.

K is the derating coefficient of the braking resistor. A small value of K prevents the

braking resistor from overheating. K can be increased properly if the heat dissipation

condition is good, but cannot exceed 50%. Otherwise, the braking resistor may be

overheated, which may cause a fire.

Braking frequency (D) is determined by applications. Typical values of braking

frequency in different applications are listed in "

Table 4–8

"

on page 105

.

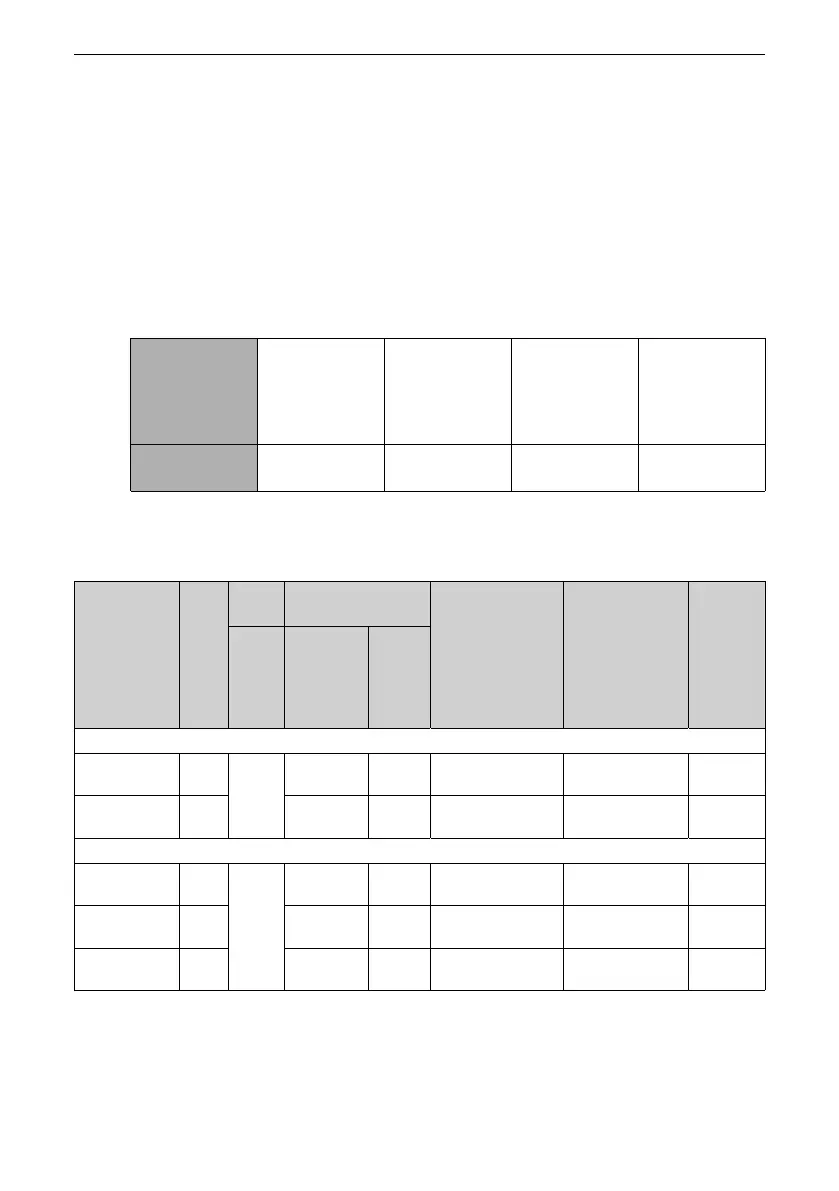

Table 4–8 Typical values of braking frequency in different applications

Application General

applications

(such as

translational

conveying)

Vertical lifting Machine tool

spindle

Winding and

unwinding

Braking

Frequency

10% 20% to 30% 30% to 50% 20% to 30%

Braking Unit Models

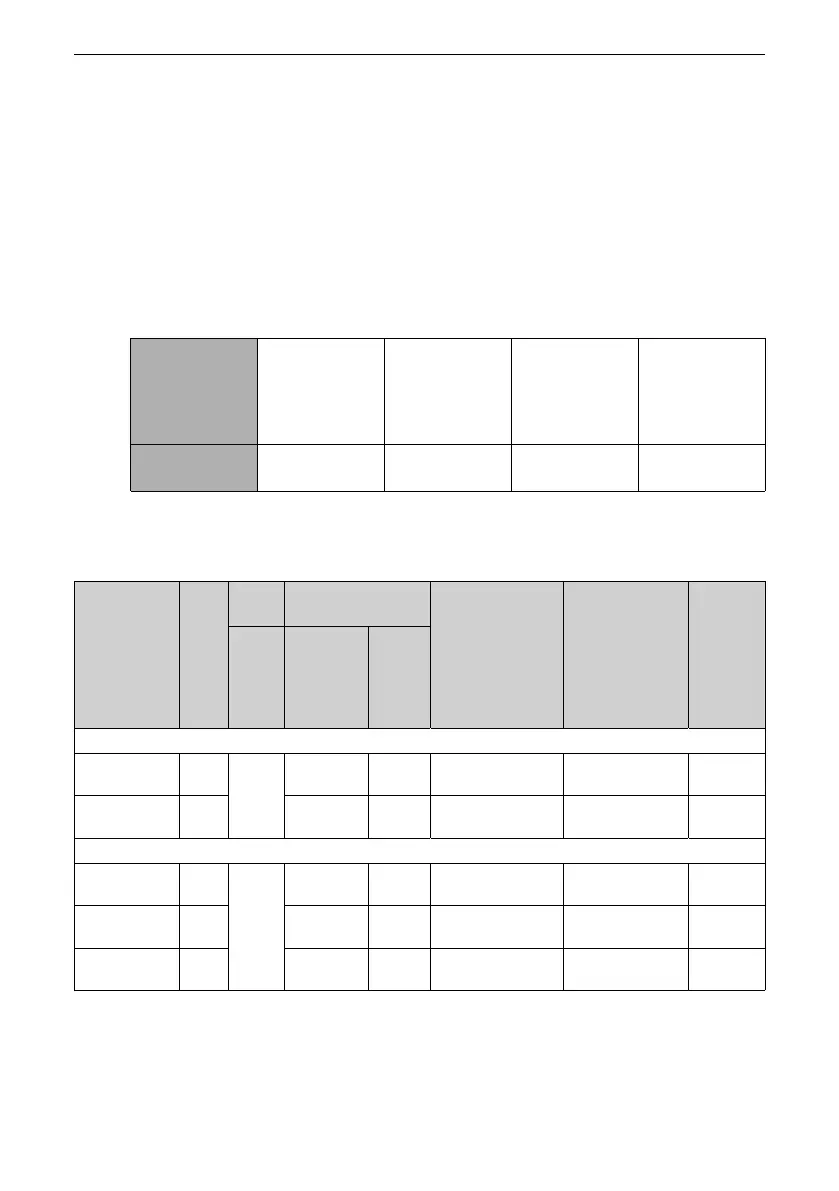

Table 4–9 Model selection of braking component

Model of Power

Supply Unit

Total

Power

of

Drive

Unit

(kW)

Braking

Unit

125% Braking Torque

(10% ED; Max. 10s)

Minimum Braking

Resistance (Ω)

Maximum Braking

Current (A)

Braking

Power (kW)

Model Recommend

ed Braking

Resistor

Specifica

tions

Number

of

Braking

Resistors

Single‑phase 200–240 V

MD800‑0‑2S24

MD800‑0‑2S24B

2.2 Built‑in

option

al

450 W 66 Ω 1 40 10 2.8

MD800‑0‑2S40

MD800‑0‑2S40B

3.7 740 W 40 Ω 1 20 20 4.7

Three‑phase 380–480 V

MD800‑0‑4T12

MD800‑0‑4T12B

3.7 Built‑in

option

al

740 W 150 Ω 1 55 15 4.7

MD800‑0‑4T22

MD800‑0‑4T22B

7.5 1500 W 75 Ω 1 32 25 9.4

MD800‑0‑4T41

MD800‑0‑4T41B

15 3000 W 38 Ω 1 20 40 18.8

Loading...

Loading...