- 107 -

5 Troubleshooting

5

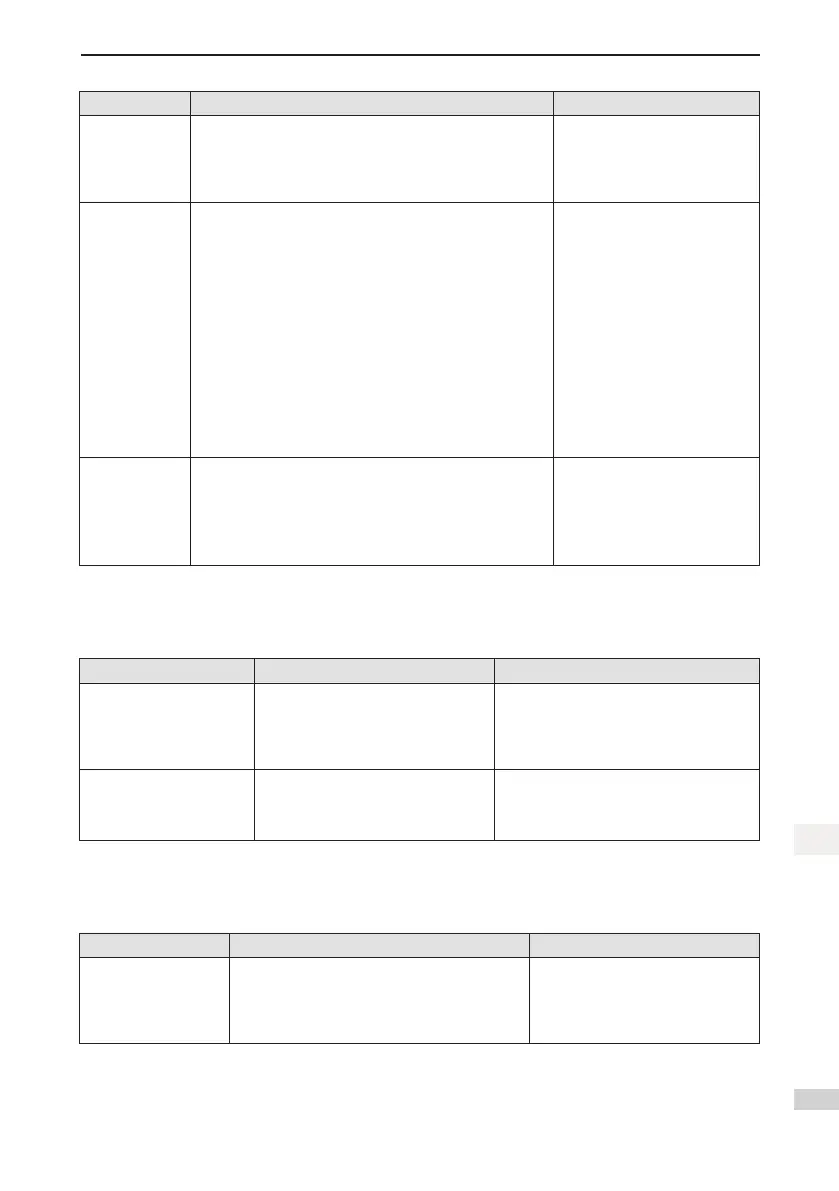

Probable Cause ConrmingMethod Corrective Action

2. Connection

of the

encoder cable

becomes

loose.

Checkwhethertheon-sitevibrationistoolarge,resulting

in encoder cable loosening and potential damage to the

encoder.

Re-connect the encoder cable

securely.

3. Interference

on Z signal of

the encoder

exists.

Checkon-sitewirings:

Checkwhetherlargeequipmentisgeneratinganinterference

on-site and whether there are interference sources such as

various variable-frequency devices inside the cabinet.

Set the servo in "Rdy" state, then manually rotate the motor

shaftanti-clockwise,andmonitorwhetherthe200B-12h

(electrical angle) increases or decreases smoothly while

number of 0-360° within one revolution is 5.

(This is for Z series motors, and for X series motors the

number should be 4.)

If 200B-12h changes abnormally during rotation, it indicates

that a fault occurs on encoder.

If there is no alarm during rotation but the system alarms

duringservorunning,itislikelythatinterferenceexists.

Preferably use the cables

recommended by Inovance.

If a non-standard cable is used,

checkwhetherthecablemeets

the requirements and is an STP

cable.

Do not bundle motor cables and

encoder cables together. Ensure

the servo motor and servo drive

are well grounded.

Checkthattheconnectorsatboth

ends of the encoder are in good

contact.

4. The encoder

is faulty.

Use a new encoder cable. If the fault no longer occurs after

replacement, it indicates that the original encoder cable is

damaged.

Place motor at the same position, power on the system

several times and observe change of 200B-12h. The

electrical angle must be within ±30°.

Use a new encoder cable.

Replace the servo motor if the

encoder is faulty.

■ E3.A33: Encoder reads and writes data abnormally

Cause:

Internal parameters of the encoder are abnormal.

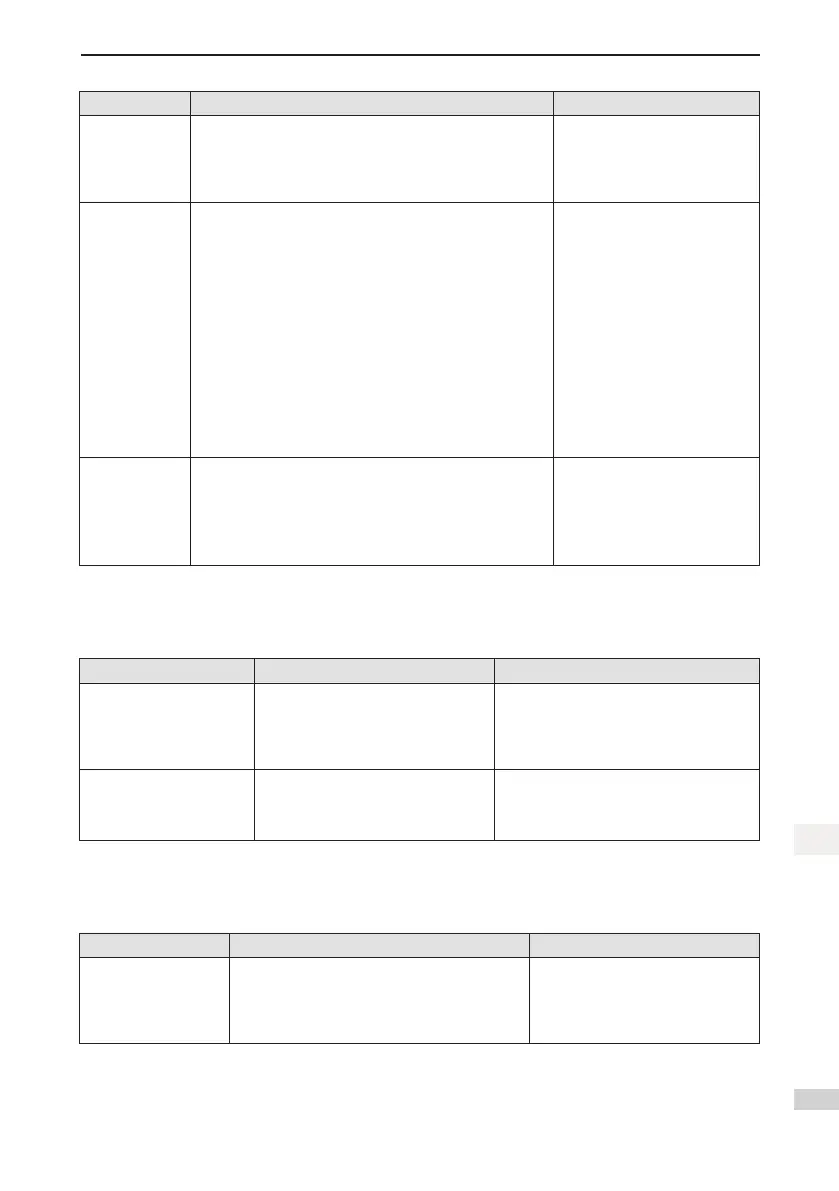

Probable Cause ConrmingMethod Corrective Action

1. The serial incremental

encodercablebreaksor

becomes loose.

Checkwirings.

Checktheconnectionoftheencoder

cable to see whether there is an incorrect

connection,brokenwiring,orapoor

contact. If motor cables and encoder cables

are bundled together, separate them.

2. Reading and writing of

the series incremental

encoder parameters are

abnormal.

If the servo drive is powered off and on

several times but the fault persists, it

indicates that the encoder is faulty.

Replace the servo motor.

■ E3.B00: Position deviation excess

Cause:

The position deviation is larger than the setting of 6065h in position control mode.

Probable Cause ConrmingMethod Corrective Action

1. Power output

(UVW) phase loss

or incorrect phase

sequence occurs in

the servo drive.

Perform motor trial running when there is no load

andcheckthemotorwirings.

Correct the wiring or replace the

cables.

Loading...

Loading...