- 108 -

5 Troubleshooting

5

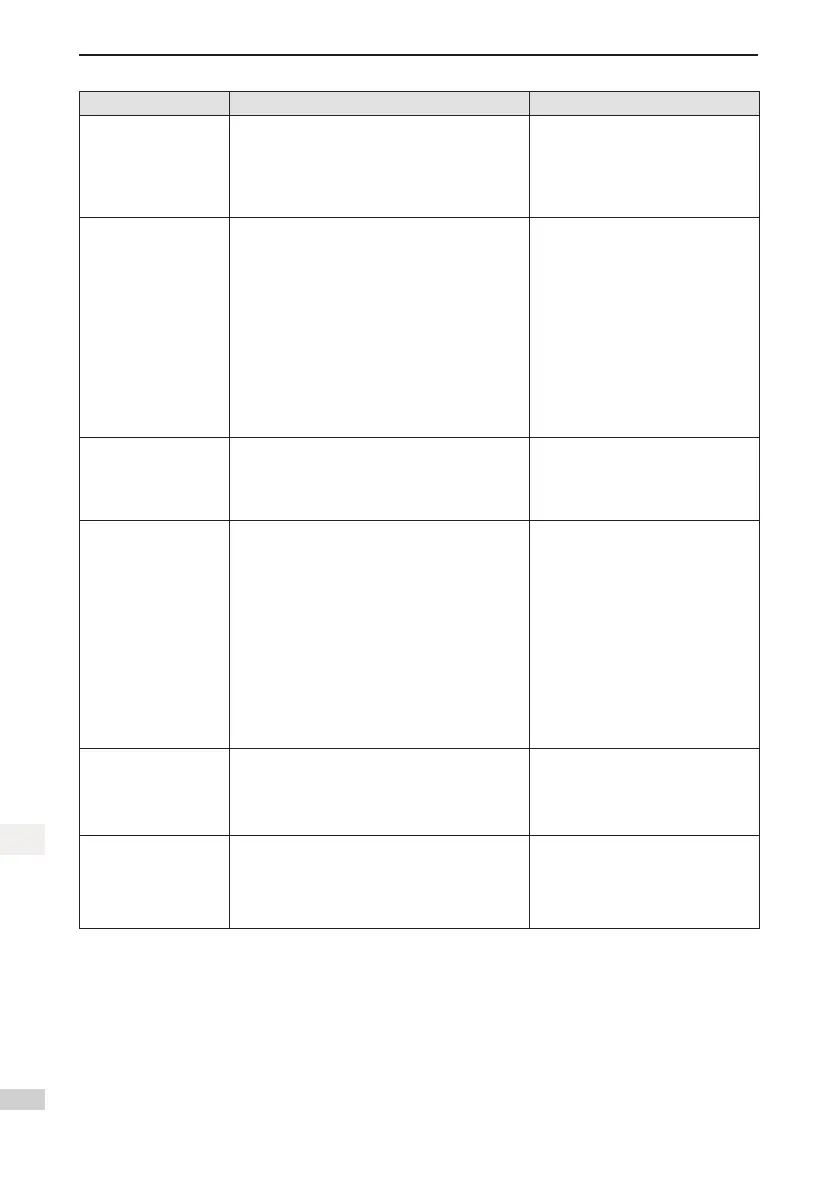

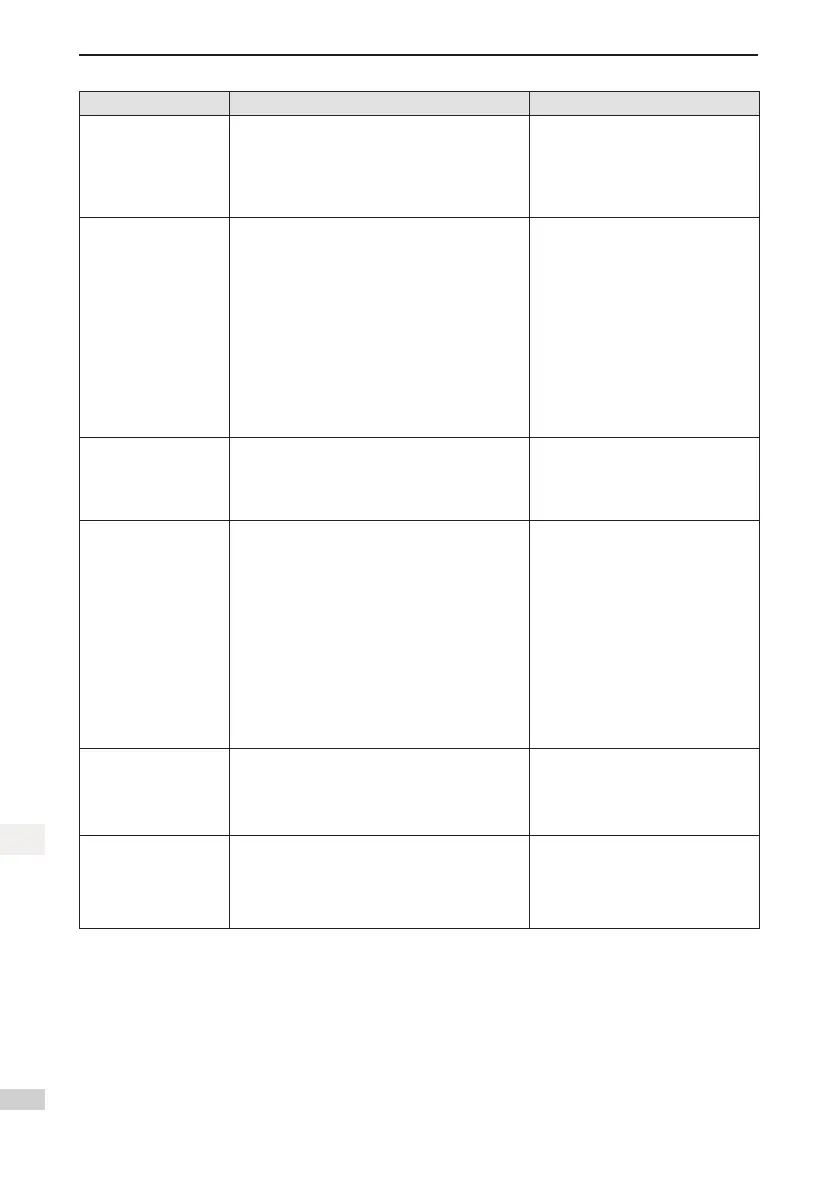

Probable Cause ConrmingMethod Corrective Action

2. The servo drive UVW

cable or the encoder

cablebreaks.

Checkwirings.

Reconnect the UVW cables. The

servo motor UVW cables must be

connected to the servo drive UVW

cables correspondingly. If necessary,

replace all cables and ensure a

reliable connection.

3. Locked-rotoroccurs

due to mechanical

factors.

Checktherunningreferenceandmotor

speed (200B-01h) through Inovance servo

commissioningsoftwareorthekeypad:

Runningreferenceinpositioncontrol:200B-0Eh

(Input position reference counter)

Runningreferenceinspeedmode:200B-02h

(Speed reference)

Runningreferenceintorquemode:200B-03h

(Internal torque reference)

Checkthattherunningreferenceisnot0butthe

motor speed is 0 in the corresponding mode.

Eliminate mechanical factors.

4. The servo drive gain

is too low.

Checkthepositionloopgainandspeedloopgain

of the servo drive.

1stgain:2008-01hto2008-03h

2ndgain:2008-04hto2008-06h

Adjust the gain manually or perform

gain auto-tuning.

5. The position

reference increment

is too large.

Positioncontrolmode:

In CSP mode, view the gear ratio 6091-01h/6091-

02htocheckthespeedreferenceincrementfora

single synchronous cycle and convert it to speed.

In PP mode, view the gear ratio 6091-01h/6091-

02handcheckthevalueof6081h(prole

velocity).

In HM mode, view the gear ratio 6091-01h/6091-

02h, and determine 6099-01h and 6099-02h.

CSP:Decreasethepositionreference

increment for a single synchronous

cycle, and the host controller needs to

increase the position ramp additionally

when generating references.

PP:Decreasethevalueof6081h,

or decrease the acceleration/

deceleration ramp (6083h, 6084h).

HM:Decrease6099-01hand6099-

02h, or decrease the acceleration/

deceleration ramp (609Ah).

Decrease the gear ratio according to

the actual conditions.

6. Relative to the

running condition,

6065h (following

error window) is too

small.

Checkwhetherthesettingof6065histoosmall. Increase the value of 6065h.

7. The servo drive or

motor is faulty.

Monitor the running curve through the oscilloscope

function in Inovance servo commissioning

software:

Positionreference,positionfeedback,speed

reference, torque reference

If the position reference is not 0, but

thepositionfeedbackisalways0,

replace the servo drive or motor.

Loading...

Loading...