- 109 -

5 Troubleshooting

5

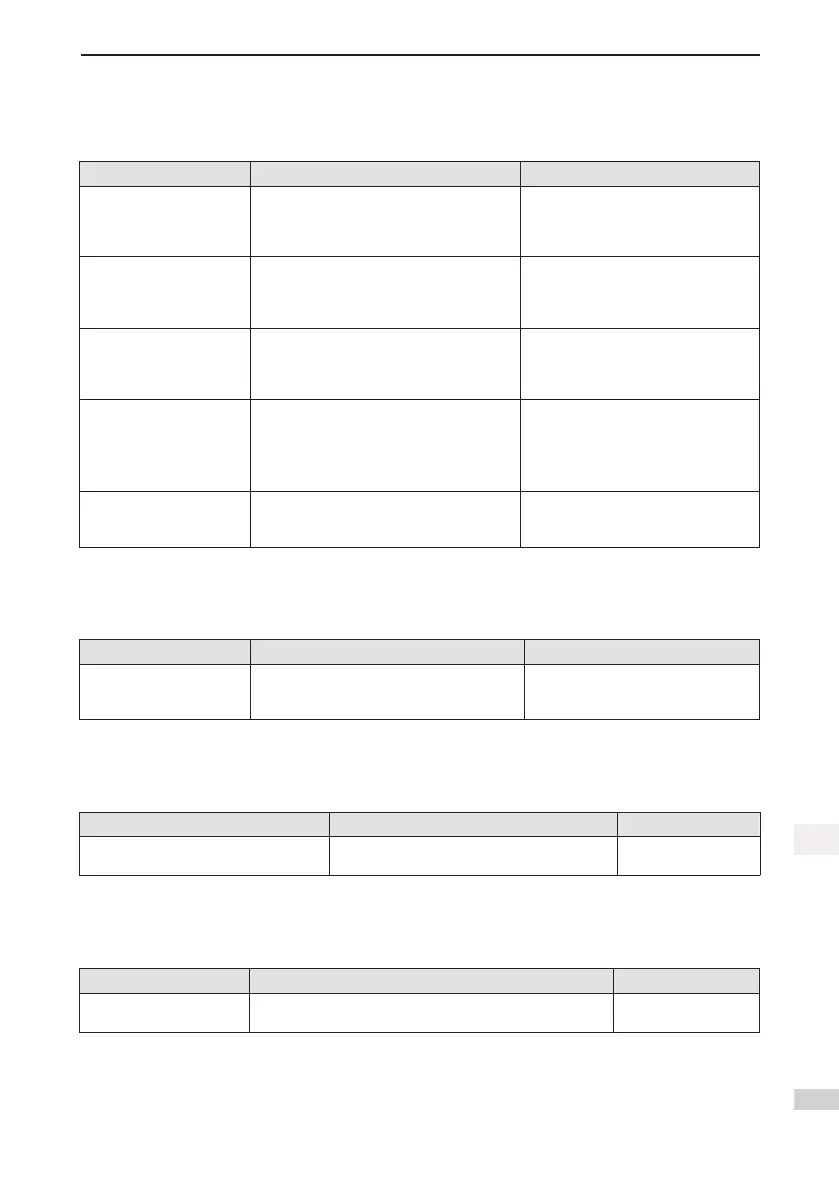

■ E3.B01: Position reference suffers abnormal increment

Cause:

Target position increment in CSP mode is too large.

Probable Cause ConrmingMethod Corrective Action

1. The position reference

increment is too large.

Checkthetargetpositionincrementofthe

adjacent synchronous cycles.

Decrease the position reference

speed, or set a certain acceleration/

deceleration curve when the host

controller plans the target position.

2. Before switching modes,

the target position is not

aligned with the current

position.

Checkwhethermodeswitchinghappenedin

the controller software.

Before mode switching, assign the

value of the current position to the

target position.

3. When the servo is

enabled, the target

position is not aligned

with the current position.

Checkwhethertheoperationofenablingthe

servo happened in the controller software.

When the servo is enabled, assign

the value of the current position to the

target position.

4. The gear ratio setting is

unreasonable.

Checkwhetherthe6091-01hand6091-02h

are set incorrectly.

Checkwhetherscalingfactorsofthehost

controller associated with machine and

motor encoder are set incorrectly.

Modify gear ratio and host controller

related scaling factors according to

practical applications.

5. Motor selection is

unreasonable.

Checkthatthemaximummotorspeedis

less than the maximum operating speed that

satiseson-sitedemand.

Re-select the motor or reduce the

maximum operating speed on site.

■ E3.B03: Electronic gear ratio setting exceeds limit

Cause:

Electronicgearratioexceedslimit:(0.001xencoderresolution/10,000,4,000xencoderresolution/10,000).

Probable Cause ConrmingMethod Corrective Action

1. The electronic gear ratio

setting exceeds the

preceding range.

Checkwhethertheratiovalueof

6091-01h/6091-02h exceeds the preceding

range.

Set the gear ratio within the required

range.

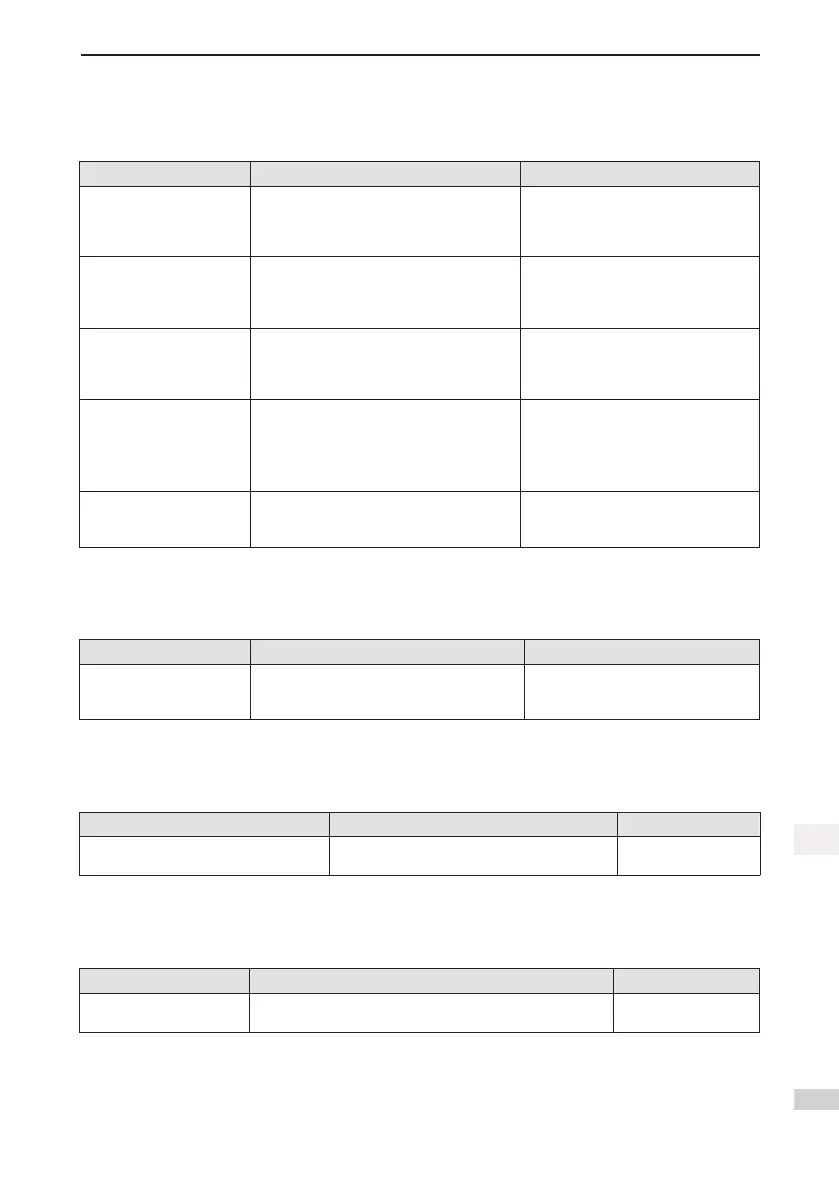

■ E3.D09: Software position setting incorrect

Cause:

The lower limit of the software position is larger than the upper limit.

Probable Cause ConrmingMethod Corrective Action

1. The lower limit of the software position

is larger than the upper limit.

The lower limit (607D-01) of the parameter soft

limit is greater than the upper limit (607D-02).

Reset the parameters.

■ E3.D10: Origin position setting incorrect

Cause:

The origin offset is outside the soft limit.

Probable Cause ConrmingMethod Corrective Action

1. The origin offset is

outside the soft limit.

The value of the parameter (607Ch) is outside the soft limit

607D-01 and the upper limit (607D-02) of the soft limit.

Reset the parameters.

Loading...

Loading...