- 97 -

5 Troubleshooting

5

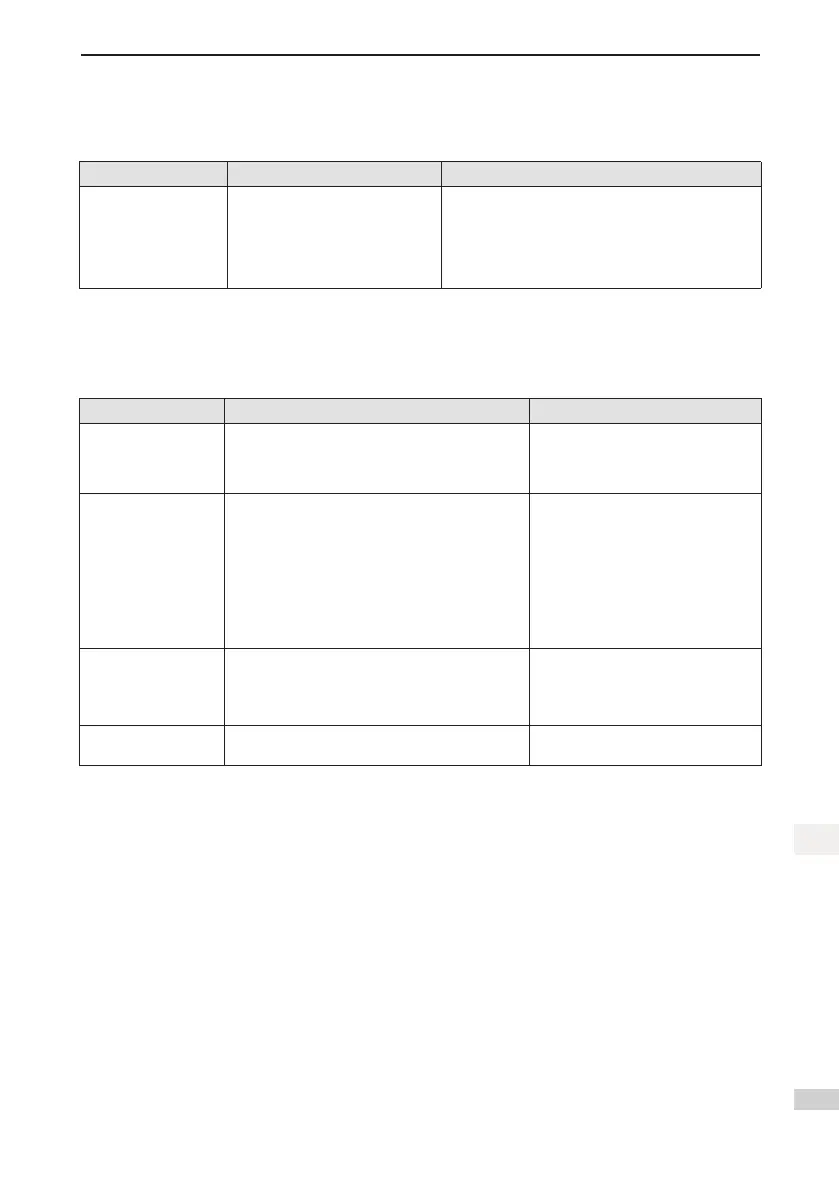

■ E3.130: different DIs allocated with the same function

Cause:

The same function is allocated to different DIs

Probable Cause ConrmingMethod Corrective Action

1. The same function is

allocated to different

DIs.

View 2003-03h, 2003-05h, 2003-

07hto2003-31htocheckwhether

they are allocated with the same

non-zero DI function No.

Allocate parameters that have been allocated with

the same non-zero DI function No. with different DI

functions. Then turn on the control power again to

allowthemodicationstotakeeffect.Youcanalso

turn the S-ON signal OFF and give the reset signal to

makethemodicationtakeeffect.

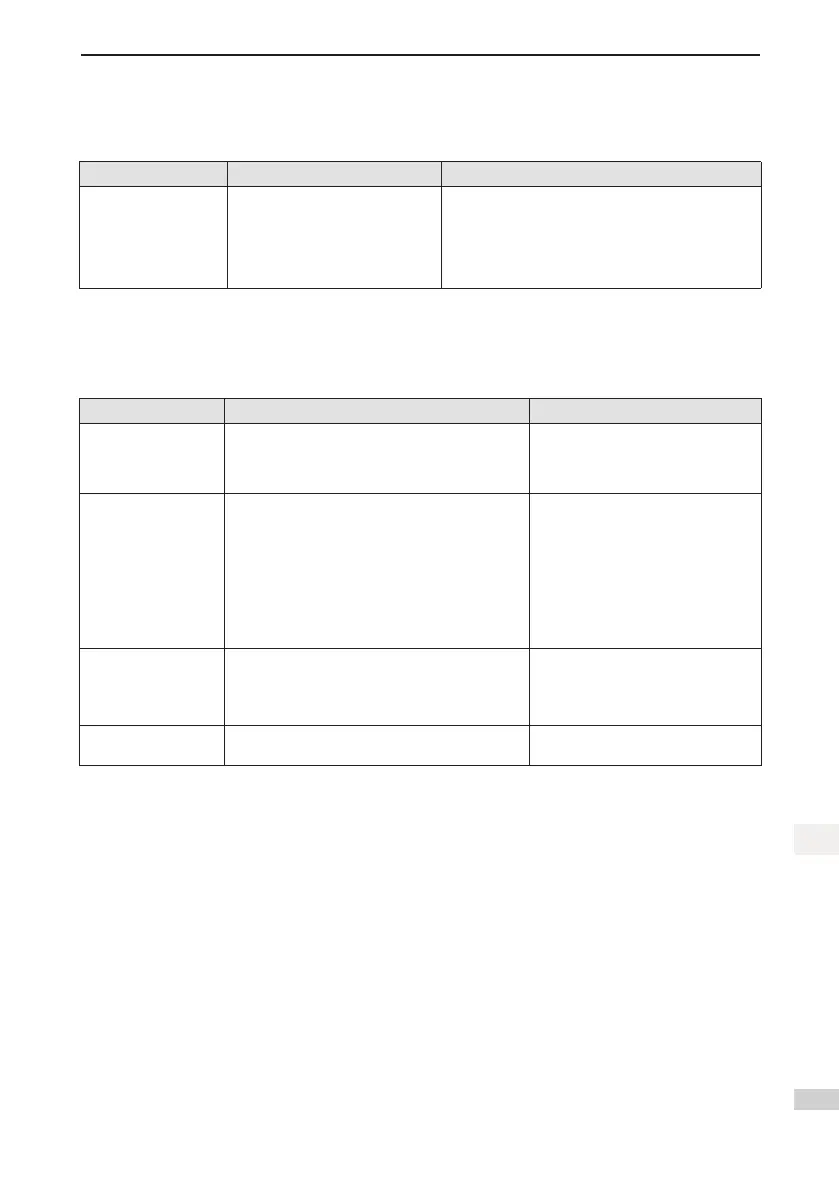

■ E3.136: Data check error or no parameter stored in the motor ROM

Cause:

When reading parameters from the encoder ROM memory, the servo drive detects that no parameters are

saved there or parameter values are inconsistent with the agreed value.

Probable Cause ConrmingMethod Corrective Action

1. The servo drive

model and the

motor model do not

match.

View the servo drive and servo motor nameplates

tocheckthattheequipmentusedistheInovance

SV820 series, servo drive and matching servo

motor.

Replace the matching servo drive and

servo motor.

2. Aparametercheck

error occurs or

no parameter is

stored in the serial

increment encoder

ROM memory.

Checkwhethertheencodercableisused

accordingtothestandardconguration.Forcable

specication,refertothe"1.6Cables"sectionon

page 21. The cable must be connected reliably

withoutscratching,breakingorpoorcontact.

MeasuresignalsPS+,PS-,+5VandGNDatboth

ends of the encoder cable and observe whether

signals at both ends are consistent. For the

denitionofsignals,refertoHardwarewiring.

Use the recommended encoder cable.

Ensure that the cable is connected

to the motor securely and tighten the

screws on the drive side. If necessary,

use a new encoder cable.

Never bundle encoder cable and

power cables (RST, UVW) together.

3. The encoder wiring

is incorrect or

disconnected.

Checktheencoderwiring.

Checkwhethertheon-sitevibrationistoolarge,

resulting in encoder cable loosening and potential

damage to the encoder.

Connect the encoder cable correctly.

Re-connect the encoder cable

securely.

4. The servo drive is

faulty.

The fault persists after the servo drive is powered

on again.

Replace the servo drive.

■ E3.150: STO input protection

Cause:

STO input protection

Loading...

Loading...