- 98 -

5 Troubleshooting

5

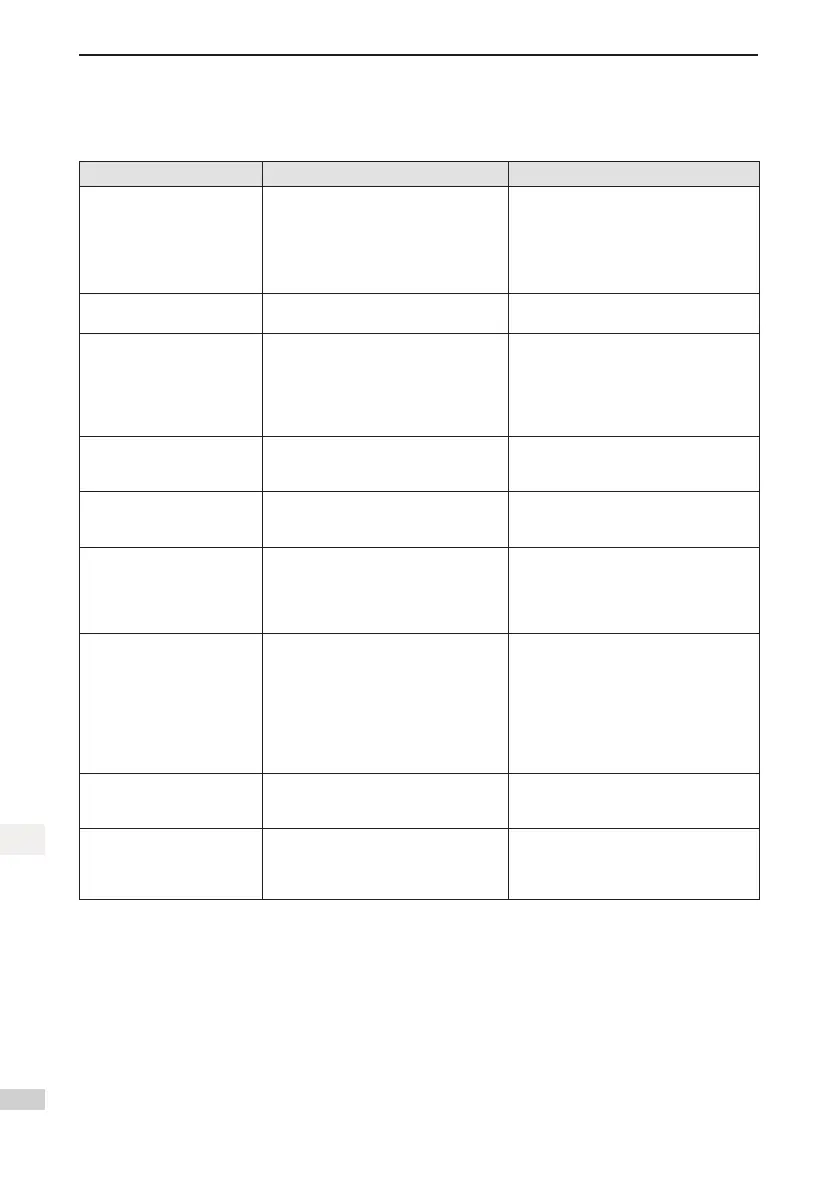

■ E3.201: Overcurrent

Cause:

Hardware overcurrent is detected.

Probable Cause ConrmingMethod Corrective Action

1. References are input

simultaneously at the

servo drive startup or

the reference input is too

early.

Checkwhetheranreferenceisinput

beforethekeypaddisplays"ry."

Referencesequence:Afterthekeypad

displays "ry", turn on S-ON signal and

input reference.

Ifallowed,addreferenceltertime

constant or increase acceleration/

deceleration time.

2. The motor cables are in

poor contact.

Checkwhethertheservodrivepower

cables and motor UVW cables are loose.

Tighten the cables that are loose or are

disconnected.

3. The motor cables are

grounded.

After ensuring the servo drive power

cables and motor cables are connected

securely, measure whether the insulation

resistance between the servo drive UVW

cablesandgroundcable(PE)isMΩ-

level.

Replace the motor if the insulation is

poor.

4. The motor UVW cables

are short circuited.

Disconnectthemotorcablesandcheck

whether they are short circuited and

whether burrs exist.

Connect the motor cables correctly.

5. The motor is damaged.

Disconnect the motor cables and

measure whether the resistance

between motor cables UVW is balanced.

Replace the motor if the resistance is

unbalanced.

6. The gain setting is

improper and the motor

oscillates.

Checkwhetherthemotoroscillatesor

generates a shrill noise during motor

startup and running. You can view

"currentfeedback"byusingthedrive

Inovance servo commissioning software.

Carry out gain adjustment.

7. The encoder cable

is incorrectly wired,

corrosive, or inserted

loosely.

Checkwhethertheencodercable

is used according to the standard

conguration.Checkwhetherthecable

is aging, corrosive or loose.

Turn off the S-ON signal, rotate the

motorshaftmanually,andcheckwhether

200B-12h (Electrical angle) changes as

the motor rotates.

Re-weld, fasten or replace the encoder

cable.

8. The servo drive is faulty.

The fault persists after the motor cables

are disconnected and the servo drive is

powered on again.

Replace the servo drive.

9. Bleeder resistor

overcurrent

Checkwhetherexternalbleederresistor

resistance value is small or the bleeder

resistor is short-circuited (P and C ends

at main circuit input terminal).

Select new resistance value and model of

the bleeder resistor.

Perform the wiring again.

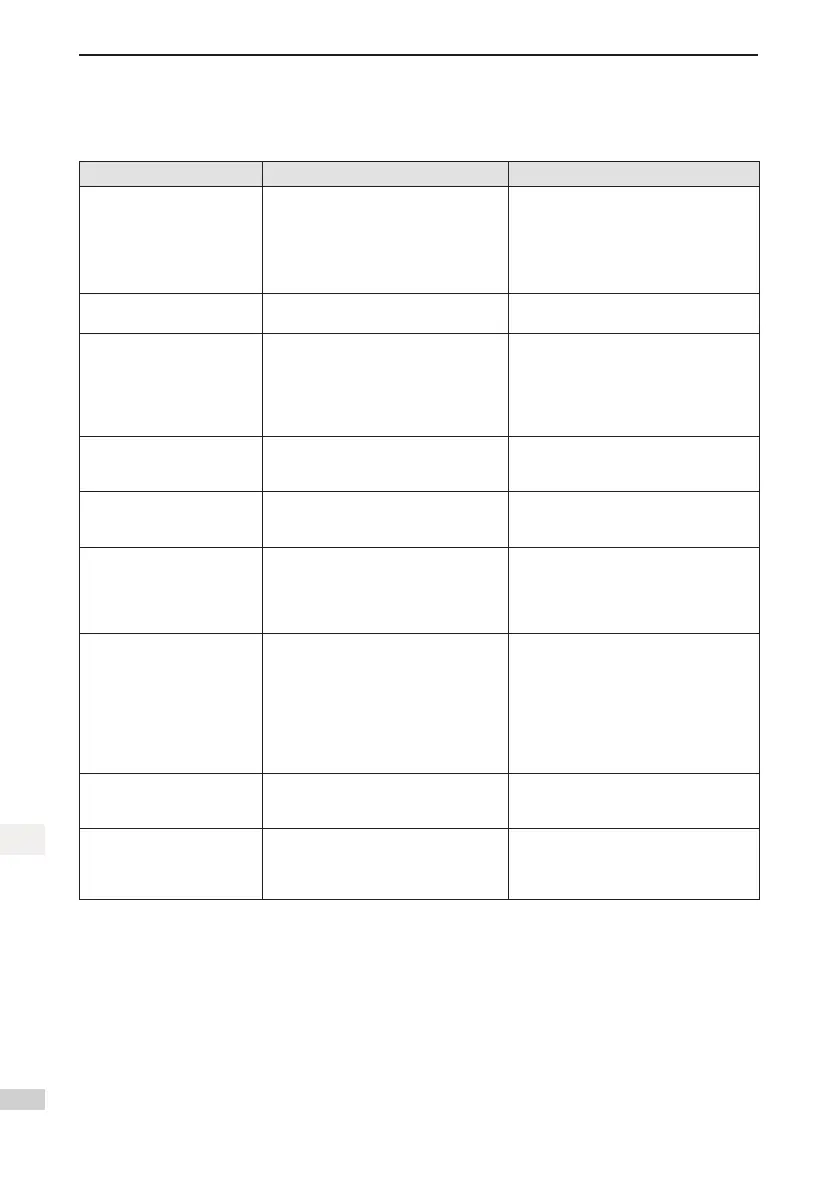

■ E3.202: Soft-start relay wire-breaking

Cause:

Soft-startrelayiswire-breaking.

Loading...

Loading...