Intermec EasyCoder F2 – Installation & Operation Ed. 2 79

Chapter 11 Maintenance

Cleaning the

Paper Guides

Both parts of the label stop sensor, which controls the paper feed, are

covered by plastic guides. The guides are provided with seemingly

non-transparent areas, through which the light between the two

parts of the label stop sensor is transmitted. These areas (indicated

by a shade of grey in illustration #2 below) must be kept clean from

dust, stuck labels, and adhesive residue.

If the printer starts to feeed our labels in an unexpected way. lift the

upper guide – as described below – and check for anything that may

block the beam of light (dust, stuck labels, adhesive residue etc.).

If necessary, clean the guides using a cleaning card or a soft cloth

soaked with isopropyl alcohol. Do not use any other the of chemical.

Be careful not to scratch the guides.

Caution!

Isopropyl alcohol [(CH

3

)

2

CHOH; CAS 67-63-0] is a highly

fl ammable, moderately toxic and mildly irritating substance.

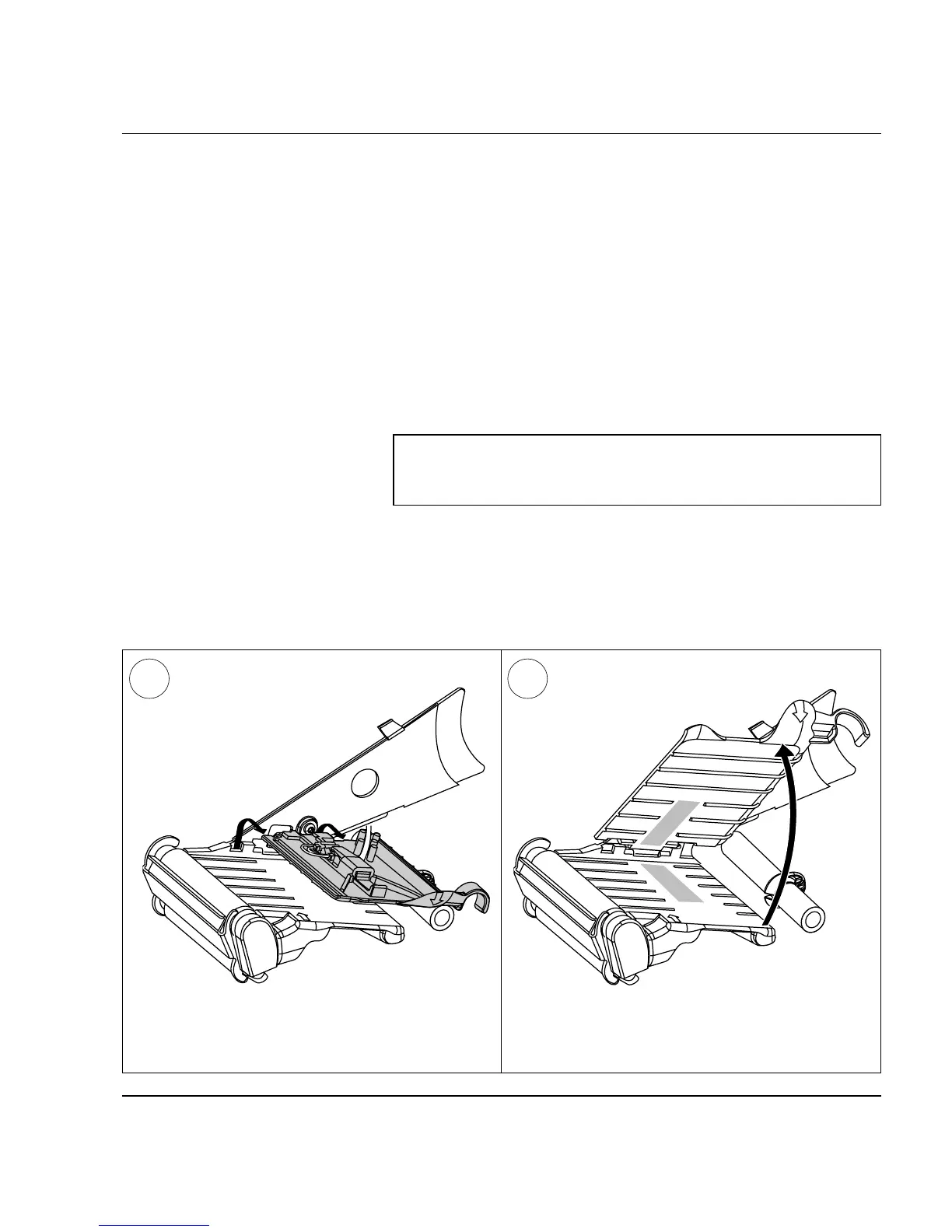

Lift the inner part of the upper guide and

pull it outwards,disengaging it from the lower

guide. Take care not to damage the cable.

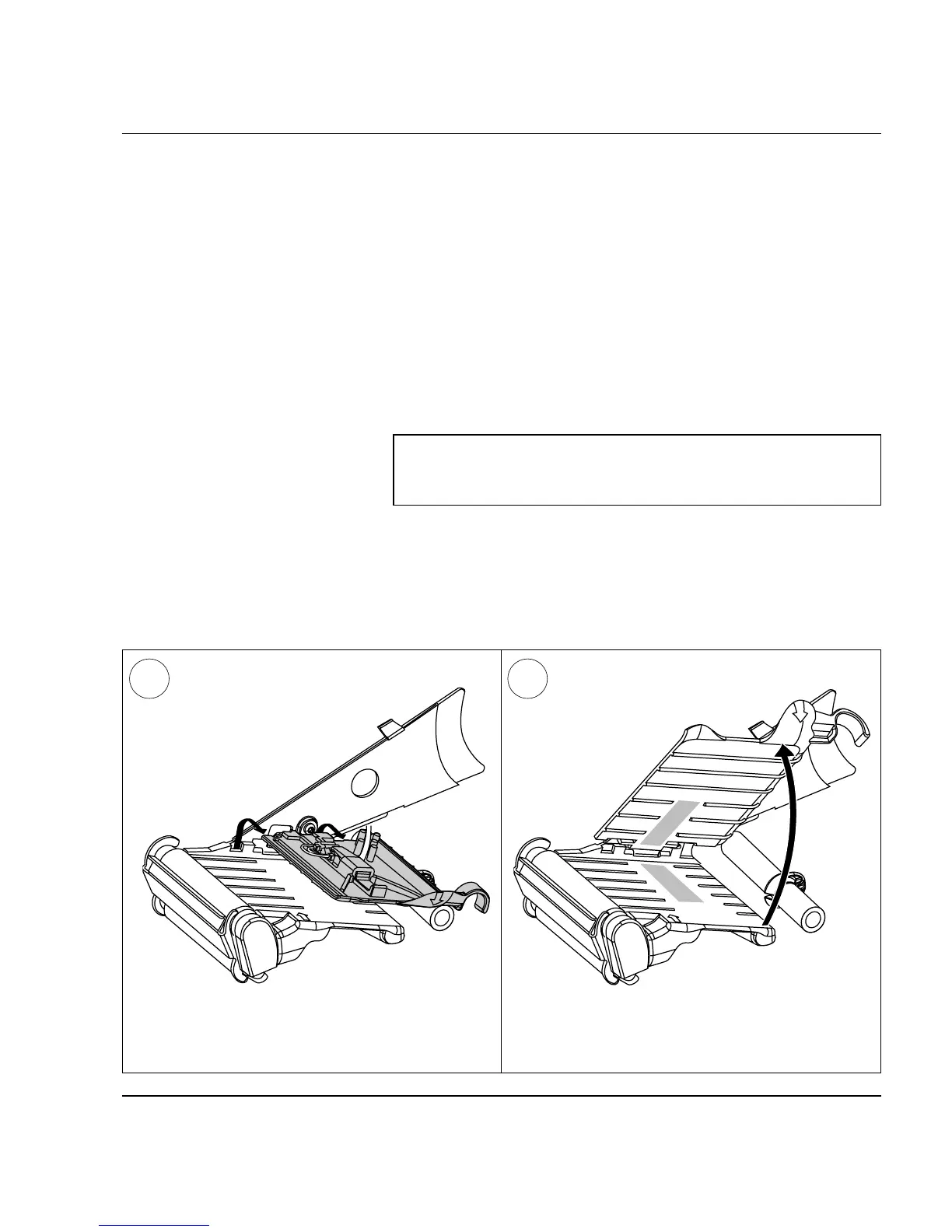

Tilt the upper guide upwards and clean the

areas marked with grey. After cleaning, reas-

semble in reverse order.

1 2

Loading...

Loading...