Product description

INTORQ | BA 14.0168 | 11/2018 16

¾

Furthermore, all specified restrictions apply to the standard and wear-resistant friction linings (e.g. per-

missible operating frequency, permissible friction work, reactivation during operation as a holding

brake, breakaway torque after extended rest, temperature range, etc.).

The classification of the safety function of our brakes is based on the performance levels PL in accordance

with DIN EN ISO 13849-1:2015. This can be used to support the verifications of the functional safety of

drive systems. The safety characteristic data are available on request.

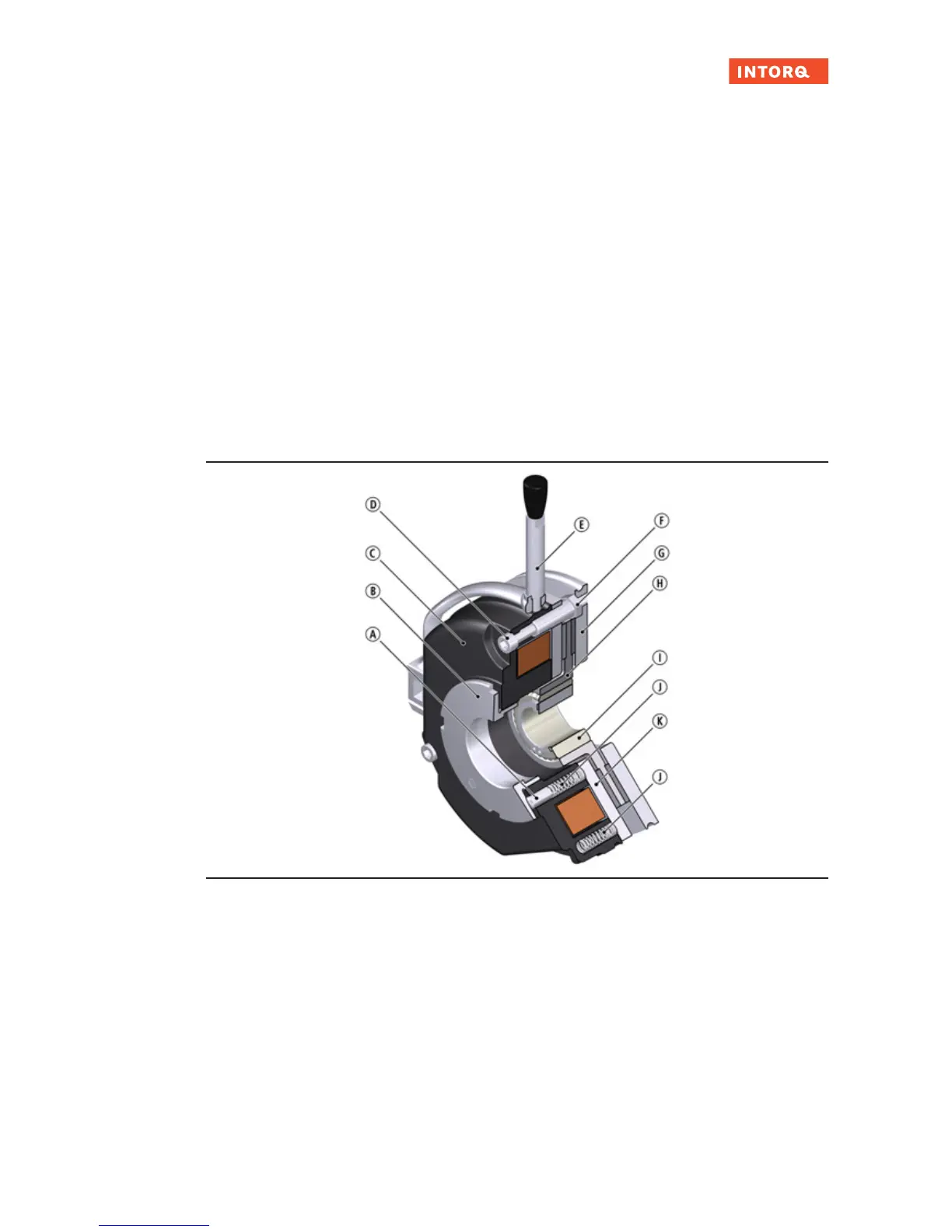

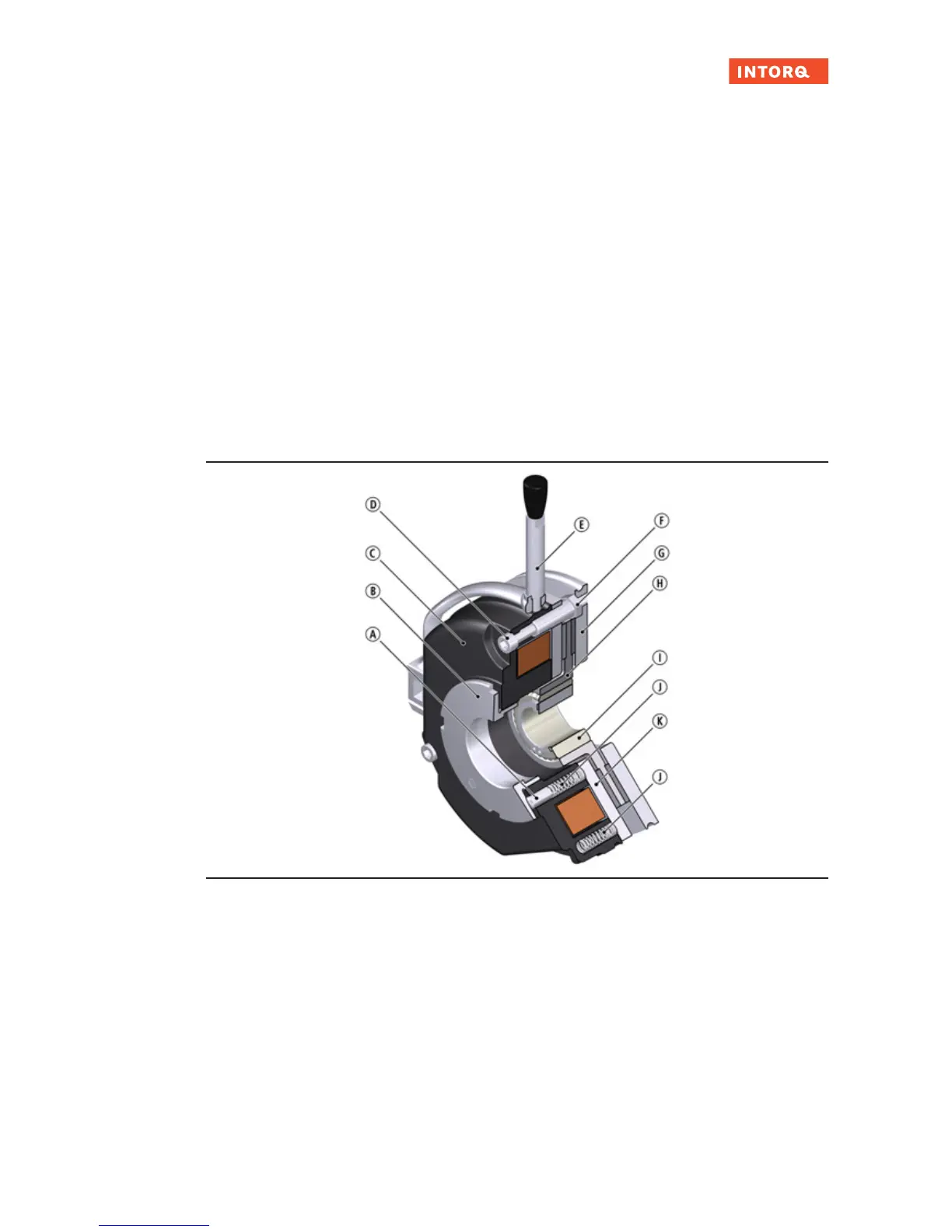

3.2 Layout

This chapter describes the variants, layout and functionality of the INTORQ BFK458 spring-applied brake.

The basic module E is adjustable (the braking torque can be reduced using the torque adjustment ring).

The special feature for basic module L (with an identical design) is the more durable materials (torque sup-

port, guide pins, toothed intermediate ring, friction lining and gear teeth). The double spring-applied brake

design is especially useful in redundant braking applications.

3.2.1 Basic module E

Fig.1: Design of the INTORQ BFK458 spring-applied brake: Basic module E (complete stator) + rotor + hub + flange

A

Tappet

B

Torque adjustment ring

C

Stator

D

Socket head cap screw

E

Hand-release (optional)

F

Sleeve bolt

G

Flange

H

Rotor

I

Hub

J

Pressure spring

K

Armature plate

Loading...

Loading...