Mechanical installation

INTORQ | BA 14.0168 | 11/2018 36

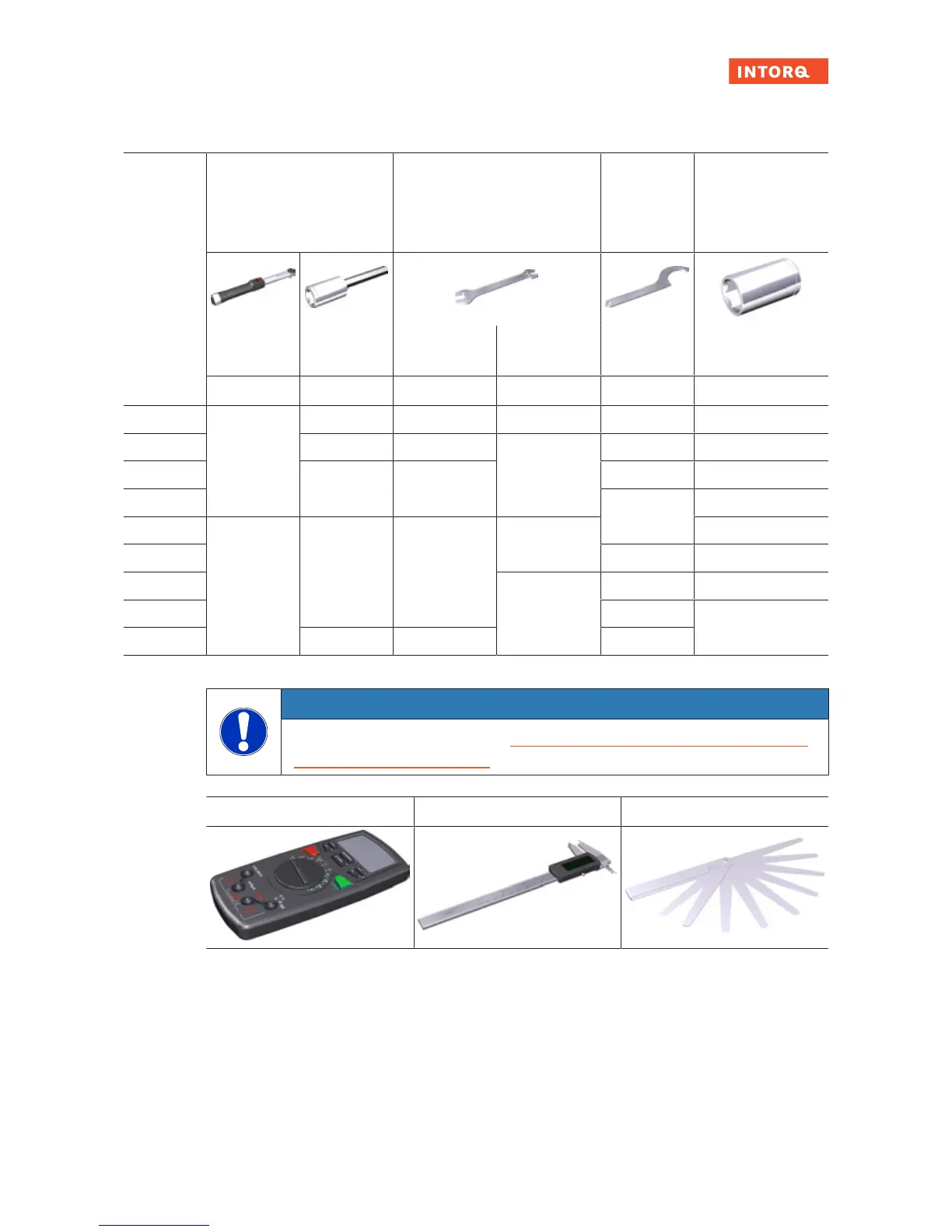

5.2 Tools

Size Torque wrench

Insert for

hexagonal socket (Allen)

screws

Open-end wrench

Width across flats

Hook wrench

DIN 1810

Type A

Socket wrench for

external flange

mount

Measuring

range

Wrench

width

Sleeve bolts Hand-release

screws

Diameter Width across flats

[Nm] [mm] [mm] [mm] [mm] [mm]

06

1 to 12

3 8 7 / 5.5 45 - 55 -

08 4 9

10 / 7

52 - 55 -

10

5 12

68 - 75 -

12

80 - 90

-

14

20 to 100

6 15

12 / 8

-

16 95 - 100 -

18

- / 10

110 - 115 13

20 135 - 145

17

25 8 17 155 - 165

NOTICE

Tightening torques: refer to the table Rated data: screw kit for brake assembly on separ-

ately screwed-on flange,Page24.

Multimeter Calliper gauge Feeler gauge

5.3 Preparing the installation

1. Remove the packaging from the spring-applied brake and dispose of it properly.

2. Check the delivery for completeness.

3. Check the name plate specifications (especially rated voltage)!

Loading...

Loading...