Commissioning and operation

INTORQ | BA 14.0168 | 11/2018 61

¾

While current is being applied to the brake, make sure that the armature plate is completely tightened

and the drive moves without residual torque.

¾

Measure the DC voltage at the brake. Compare the measured DC voltage with the voltage indicated on

the name plate. The deviation must be less than ± 10%!

¾

When using bridge/half-wave rectifiers: After switching to one-way voltage, the measured DC voltage

may drop to 45% of the voltage specified on the name plate.

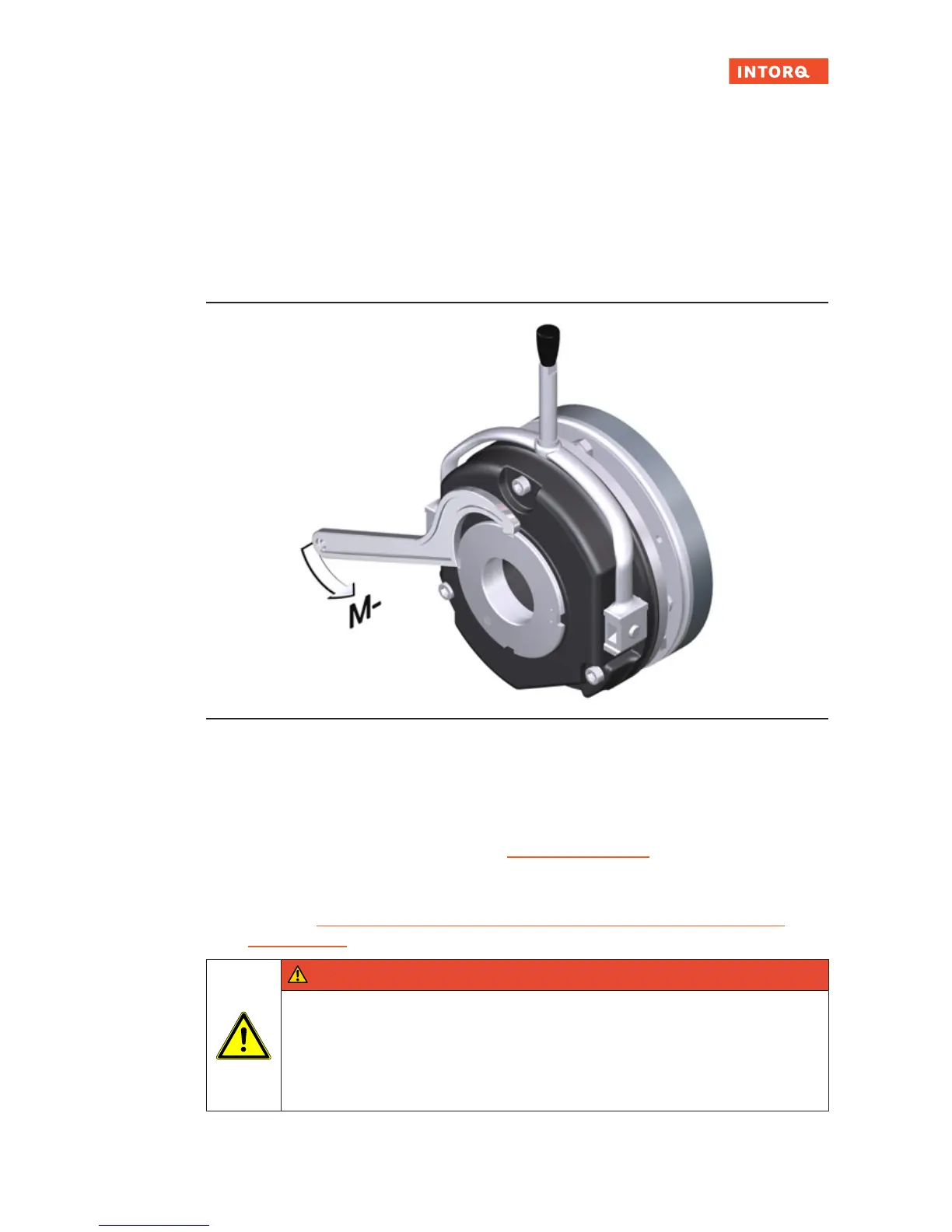

7.4.1 Brake torque reduction (for the optional adjustable braking torque)

Fig.33: Reducing the braking torque

1. Use a hook wrench to turn the torque adjustment ring counter-clockwise. This reduces the braking

torque.

– Note the correct position of the tappet notches on the torque adjustment ring: Only the latched-in

positions are permitted. It is forbidden to operate the brake when the notches are adjusted between

these latched-in positions! (Refer to chapter Brake torques

,Page21 for the values for the braking

torque reduction for each latched-in position.)

– Observe the max. permissible protrusion (h

Emax

) of the torque adjustment ring over the stator. (Refer

to the table Rated data for braking torques, depending on the speed and permissible limiting

speeds,Page23 for values of h

Emax

.)

DANGER

The reduction of the braking torque does not increase the maximum permissible air gap

s

Lmax

.

Do not change the hand-release setting for designs with hand-release.

Increasing the braking torque by screwing in the torque adjustment ring is only permitted

up to the default (as delivered) torque value .

Loading...

Loading...