Electrical installation

INTORQ | BA 14.0168 | 11/2018 54

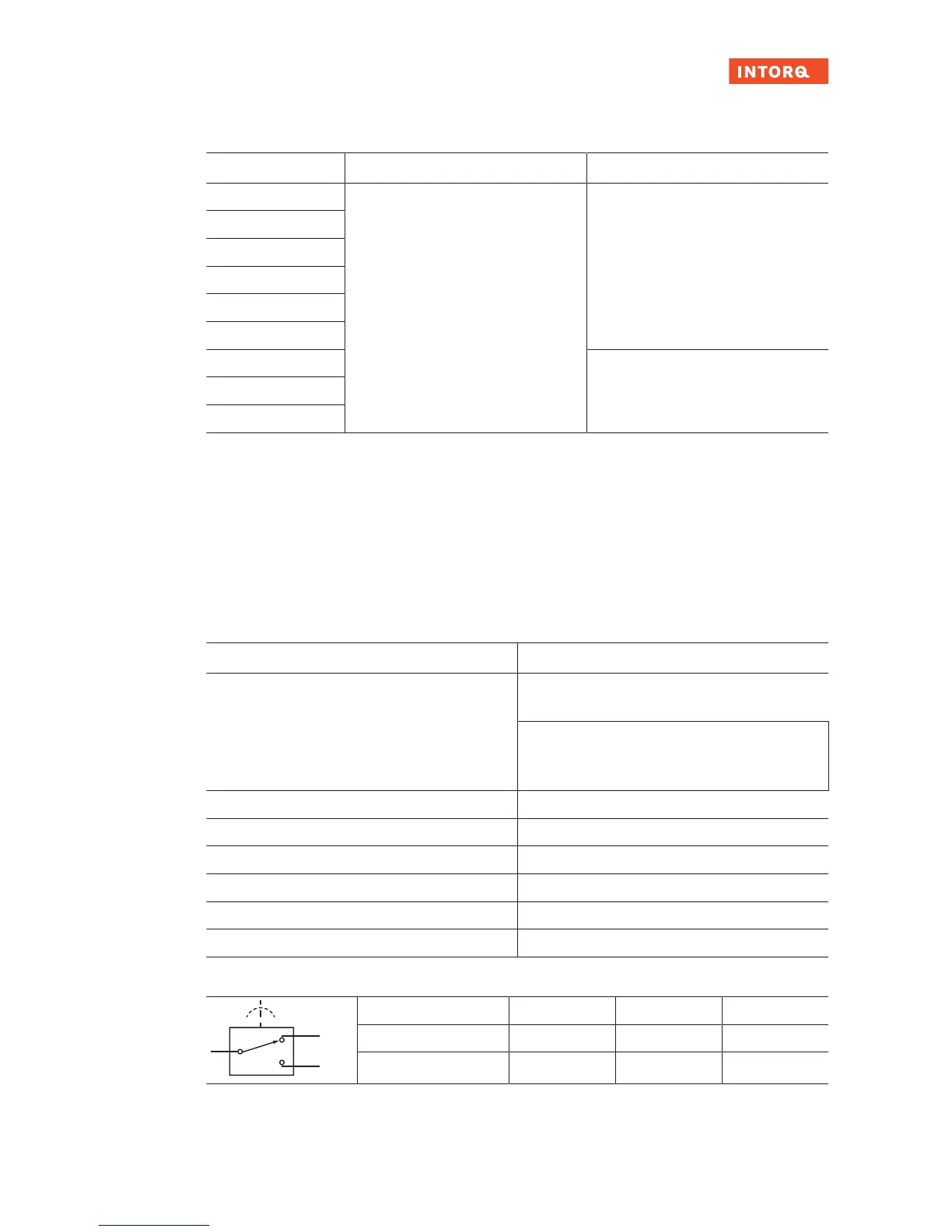

6.6 Minimum bending radius for the brake connection line

Size Wire cross-section Minimum bending radius

06

AWG 20

27.5 mm

08

10

12

14

16

18

45.6 mm20

25

Tab.13: Minimum bending radius for the brake connection cable

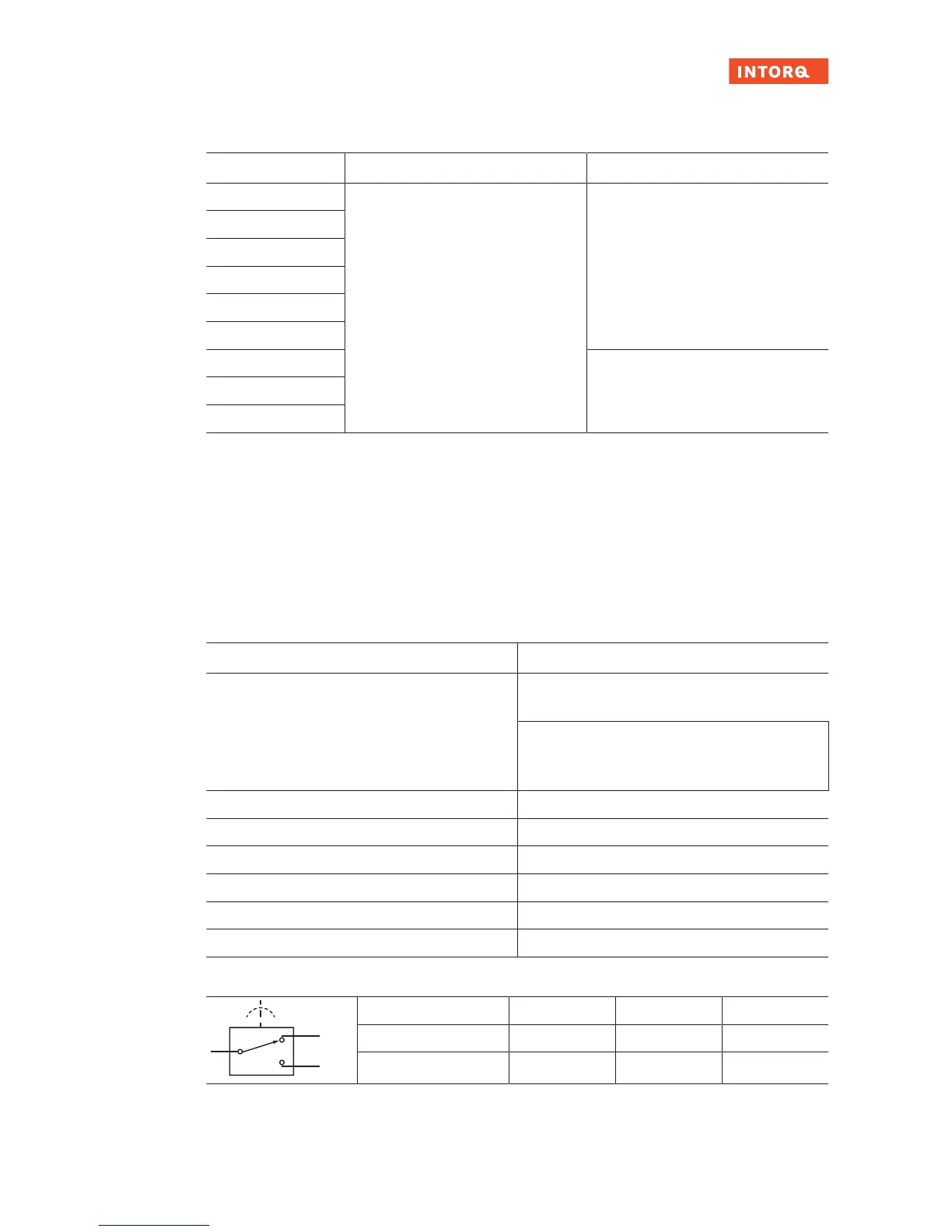

6.7 Technical specifications for the micro-switch

The brake can be equipped with a micro-switch for monitoring the release or wear. The micro-switch can

be integrated into the circuit as an NO or NC contact.

As of June 2012, a new small micro-switch (with UL acceptance) is in use, which is perfectly adapted to

the contour of the brake. The old switch design can be converted by connecting an adapter to the same

threaded holes.

Design Micro-switch

3-pole connecting cable

3 x 0.34 mm² (AWG22)

black / brown / blue

D = 4.8 mm, black, CSA

Style 2517/105°

Length: 1000 mm

Contacts Silver

Current carrying capacity 250 V AC Max. 3 A

Current carrying capacity 30 V DC Max. 3 A

Minimum load at 24 V DC 10 mA

Temperature range: -40 °C to +85 °C

Protection class IP67

Tab.14: Technical specifications for the micro-switch

Loading...

Loading...