Maintenance and repair

INTORQ | BA 14.0168 | 11/2018 64

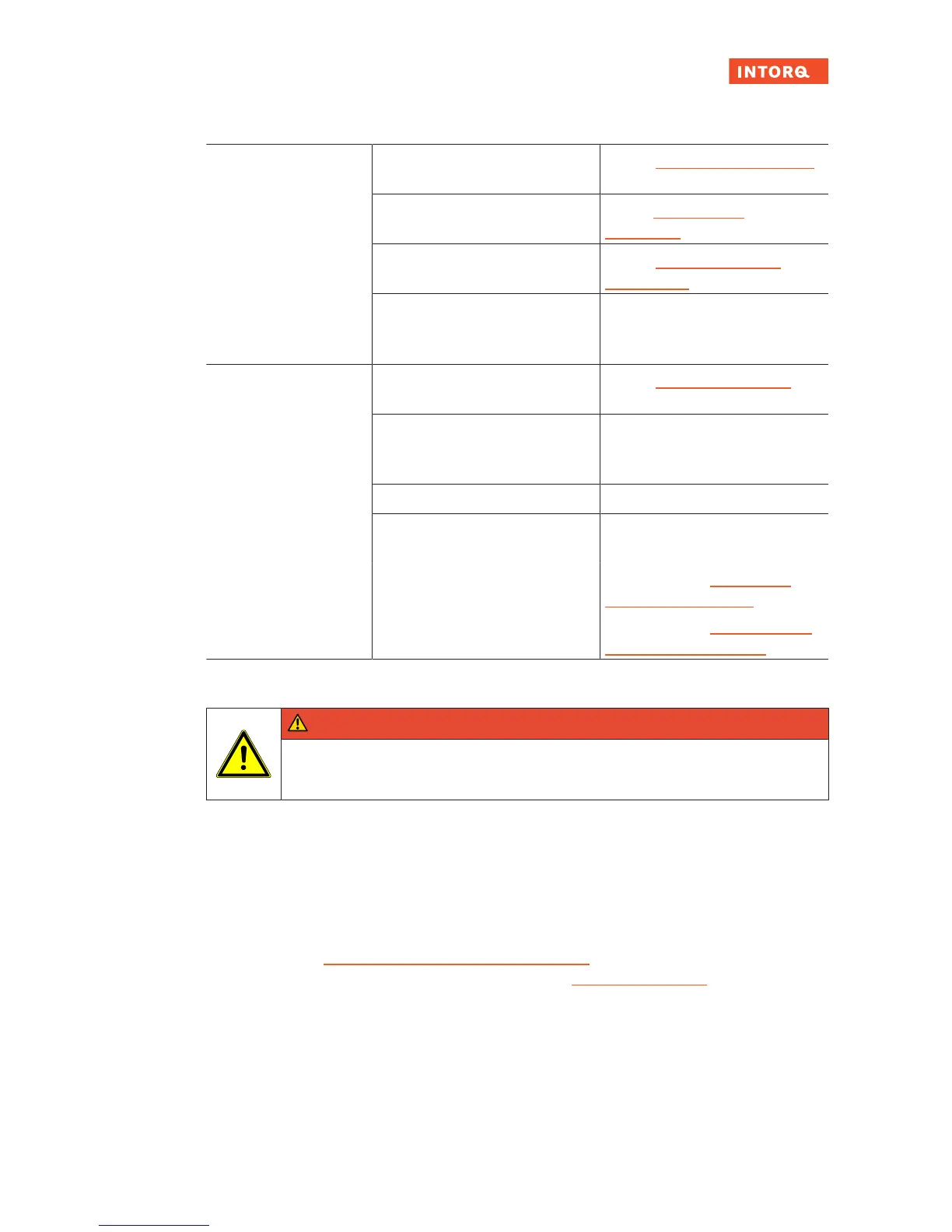

8.3.1 Checking the components

With mounted brake

¾

Check release function and con-

trol

Refer to Release / voltage,Page65

¾

Measure the air gap (adjust if re-

quired)

Refer to Adjusting the air

gap,Page66

¾

Measure the rotor thickness (re-

place rotor if required)

Refer to Check the rotor thick-

ness,Page64

¾

Thermal damage of armature

plate or flange (dark-blue tarnish-

ing)

After removing the brake

¾

Check the play of the rotor gear

teeth (replace worn-out rotors)

Refer to Replace rotor,Page66

¾

Check for breaking out of the

torque support at the guide parts

and the armature plate

¾

Check the springs for damage

¾

Check the armature plate and

flange or end shield

– Flatness depending on the

size

Refer to the table Design of end

shield and shaft,Page35

– Max. run-in depth = rated air

gap for the size

Refer to the table Rated data for air

gap specifications,Page23

8.3.2 Check the rotor thickness

DANGER

Danger: rotating parts!

The motor must not be running when checking the rotor thickness.

1. Remove the fan cover.

2. Remove the cover ring, when present.

3. Measure the rotor thickness using a calliper gauge. For the friction-plate design: observe the edging

on outer diameter of friction plate.

4. Compare the measured rotor thickness with the minimum permissible rotor thickness. (Refer to the val-

ues in the table Rated data for air gap specifications

,Page23.) If the measured rotor thickness is in-

sufficient, the rotor must be replaced completely. (Refer to Replace rotor

,Page66 for the descrip-

tion.)

Loading...

Loading...