Troubleshooting and fault elimination

INTORQ | BA 14.0168 | 11/2018 71

9 Troubleshooting and fault elimination

If any malfunctions should occur during operations, please check for possible causes based on the follow-

ing table. If the fault cannot be fixed or eliminated by one of the listed steps, please contact customer ser-

vice.

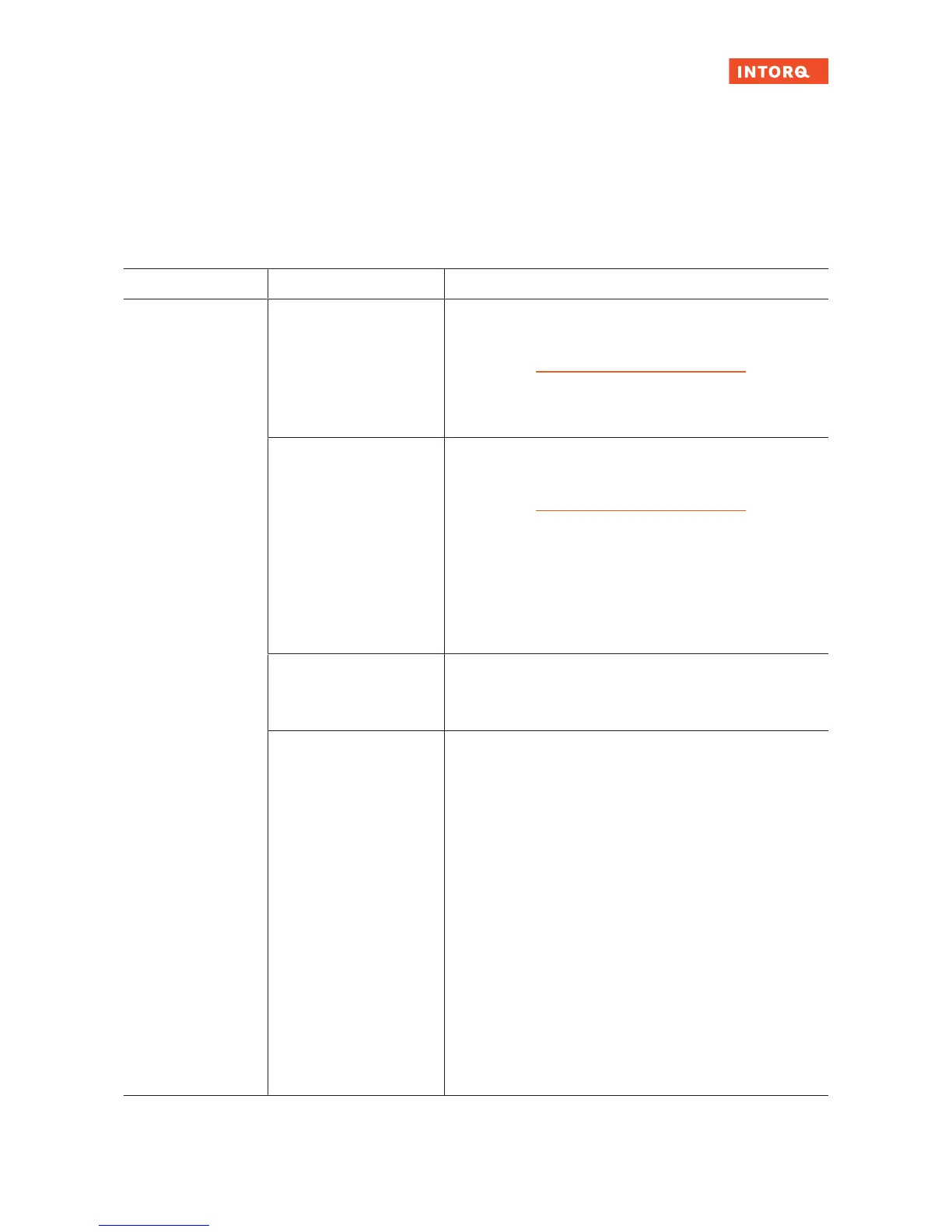

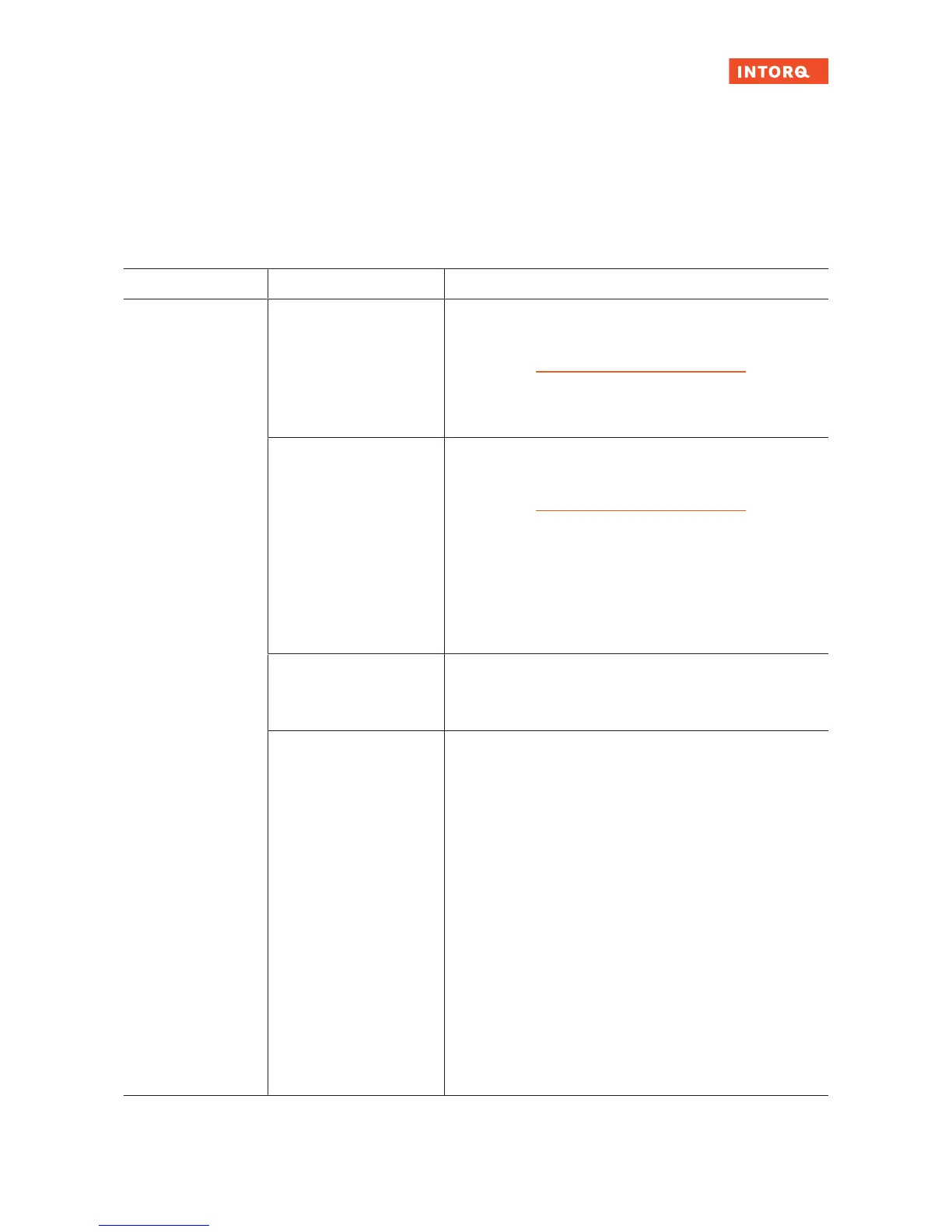

Fault Cause Remedy

Brake cannot be re-

leased, air gap is not

zero

Coil interruption

¾

Measure coil resistance using a multimeter:

- Compare the measured resistance with the nominal resist-

ance. Refer to Rated data for coil powers

,Page26 for the val-

ues.

- If resistance is too high, replace the complete spring-applied

brake.

Coil has contact to earth or

between windings

¾

Measure coil resistance using a multimeter:

- Compare the measured resistance with the nominal resist-

ance. Refer to Rated data for coil powers

,Page26 for the val-

ues. If resistance is too low, replace the complete stator.

¾

Check the coil for short to ground using a multimeter:

- If there is a short to ground, replace the complete spring-

applied brake.

¾

Check the brake voltage (refer to section on defective recti-

fier, voltage too low).

Wiring defective or wrong

Check the wiring and correct.

¾

Check cable for continuity using a multimeter

- Replace the defective cable.

Rectifier defective or incor-

rect

¾

Measure rectifier DC voltage using a multimeter.

¾

If DC voltage is zero:

¾

Check AC rectifier voltage.

¾

If AC voltage is zero:

- Switch on the voltage

- Check the fuse

- Check the wiring

¾

If AC voltage is okay:

- Check the rectifier

- Replace the defective rectifier

¾

Check coil for inter-turn fault or short circuit to ground.

¾

If the rectifier defect occurs again, replace the entire spring-

applied brake, even if you cannot find any fault between

turns or short circuit to ground. The error may only occur on

warming up.

Loading...

Loading...