Technical specifications

INTORQ | BA 14.0168 | 11/2018 25

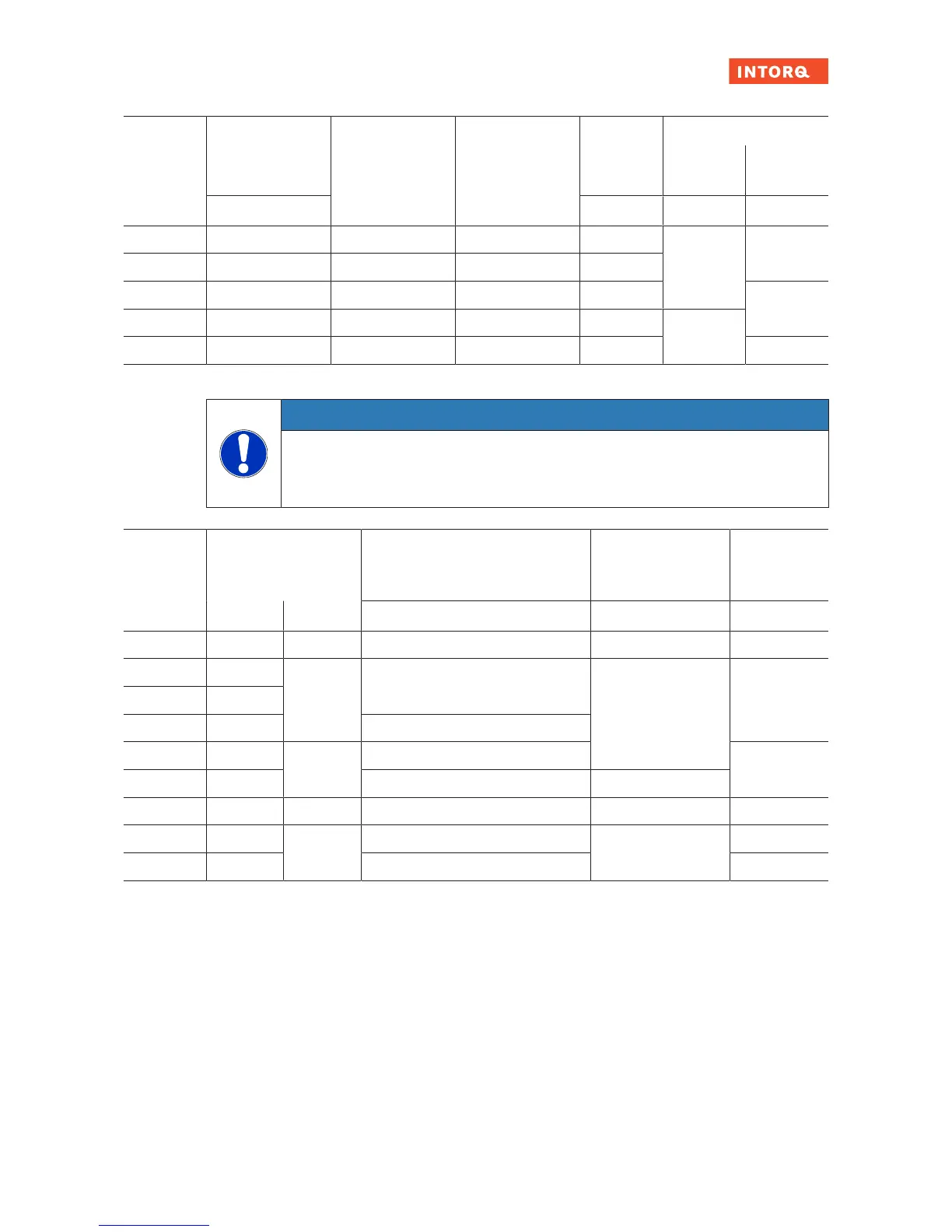

Size Screw hole circle Screw set for

mounting onto

the motor/friction

plate

Screw set for

flange with

through hole

Minimum

thread

depth

Tightening torque

Screws Lever

screws

Ø [mm] [mm] [Nm] [Nm]

14 145 3 x M8x70 3 x M8x80 18

24.6

12

16 170 3 x M8x80 3 x M8x90 22

18 196 6 x M8x90 - 22

23

20 230 6 x M10x100 - 24

48

25 278 6 x M10x110 - 28 40

Tab.7: Rated data: screw kit for brake assembly on motor, friction plate and flange with through hole

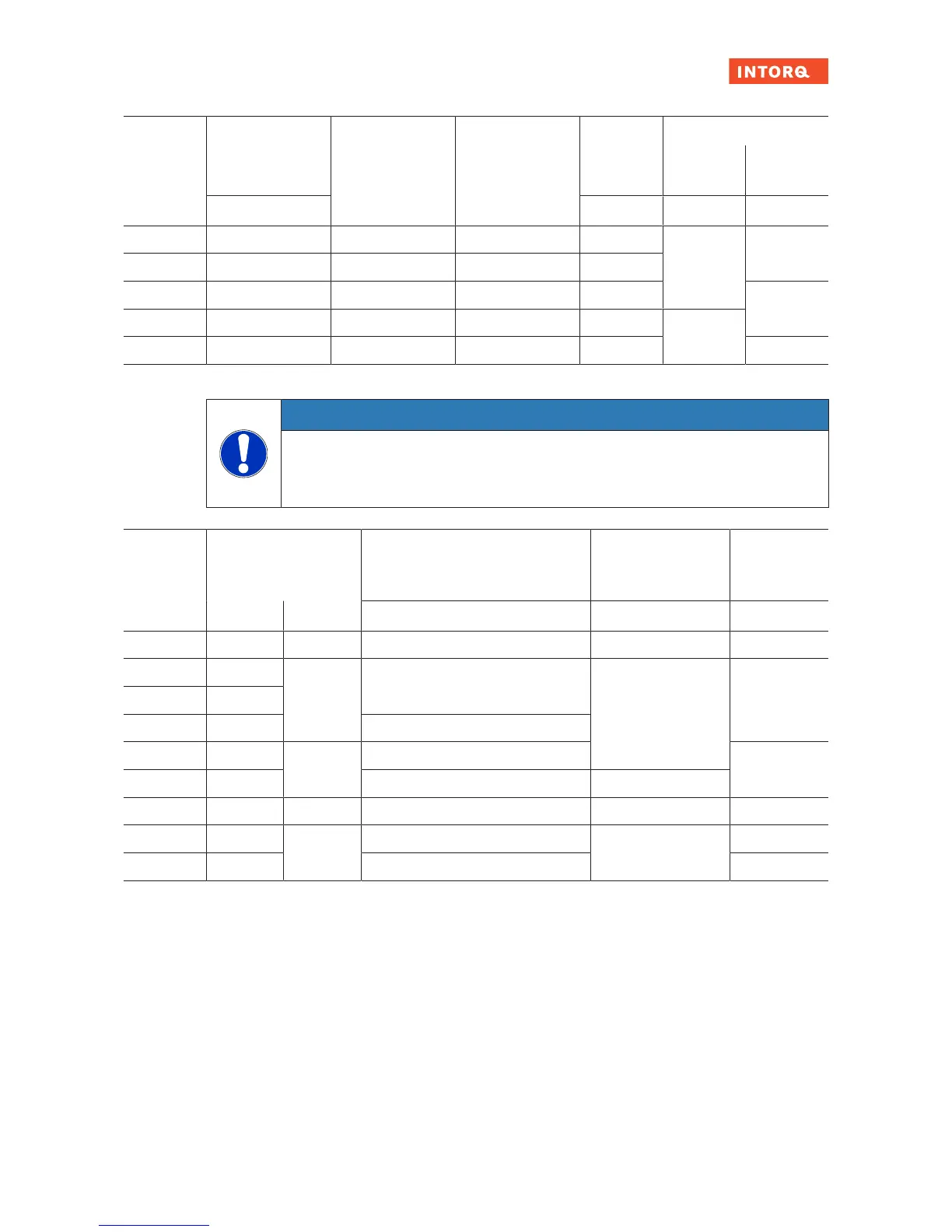

NOTICE

With the double spring-applied brake design, when working with braking torques which are

greater than the standard braking torque, you need to check the screws connecting the

first brake. Please consult with INTORQ first!

Size Screw hole circle Screw set for mounting double

flange to complete stator, DIN EN

ISO 4762 strength grade 8.8 (10.9)

Thread depth in the

magnet housing

Tightening

torque

Ø [mm] Thread

(4 pieces) [mm] [Nm]

06 37.7 4 x M4 M4x16 10 3.0

08 49

4 x M5

M5x16

12

5.910 54

12 64 M5x20

14 75

4 x M6

M6x20

10.1

16 85 M6x25 15

18 95 4 x M8 M8x25 17 24.6

20 110

4 x M10

M10x25

20

48

25 140

M10x30 – 10.9

71

Tab.8: Rated data: screw set, intermediate flange installation for double spring-applied brake

Loading...

Loading...