User manual of EC160 elevator intelligent integrated machine Running at slow speed

150

Function

code

Name Instruction

P2_05 Rated current of the motor Depend on the name plate

P3_00 Encoder type

0: Incremental encoder (AM)

1: SIN/COS encoder (synchronous 1387)

2: UVW encoder (synchronous 8192)

3: Endat encoder (synchronous 1313)

P3_01 Resolution of the encoder 1~10000

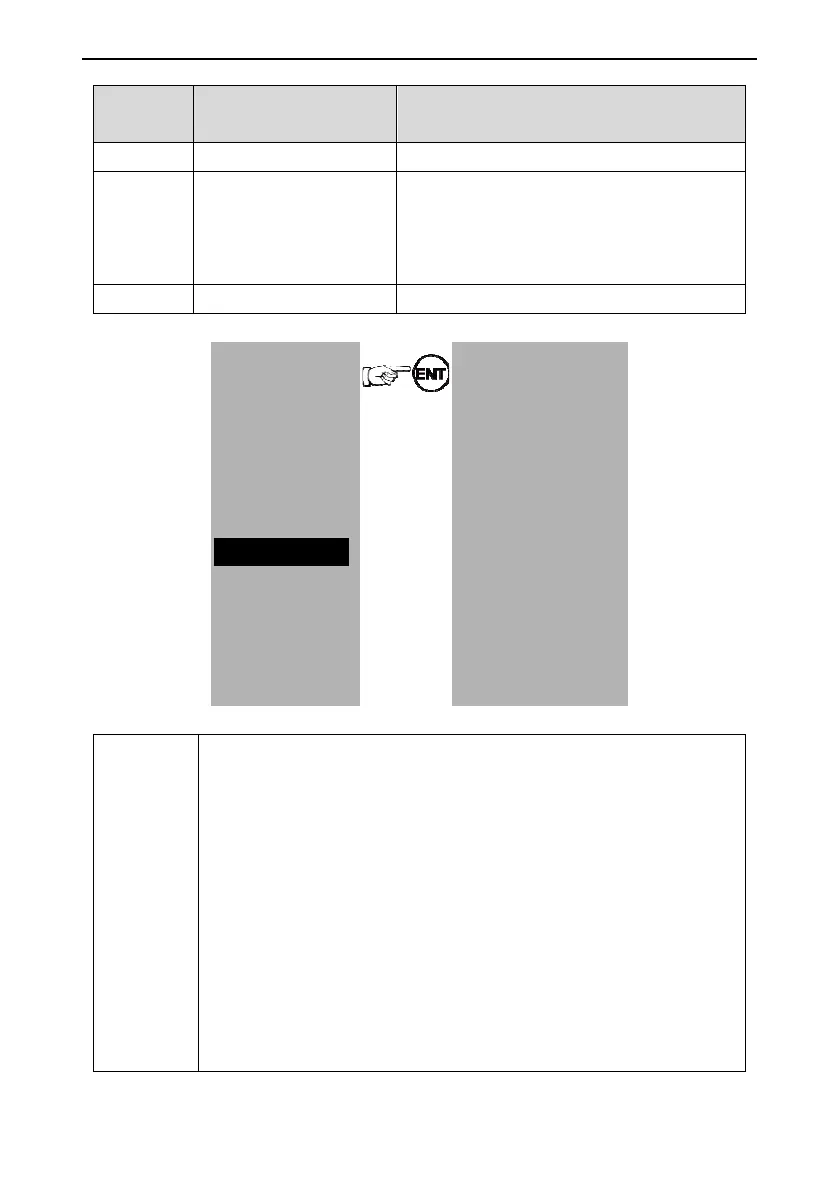

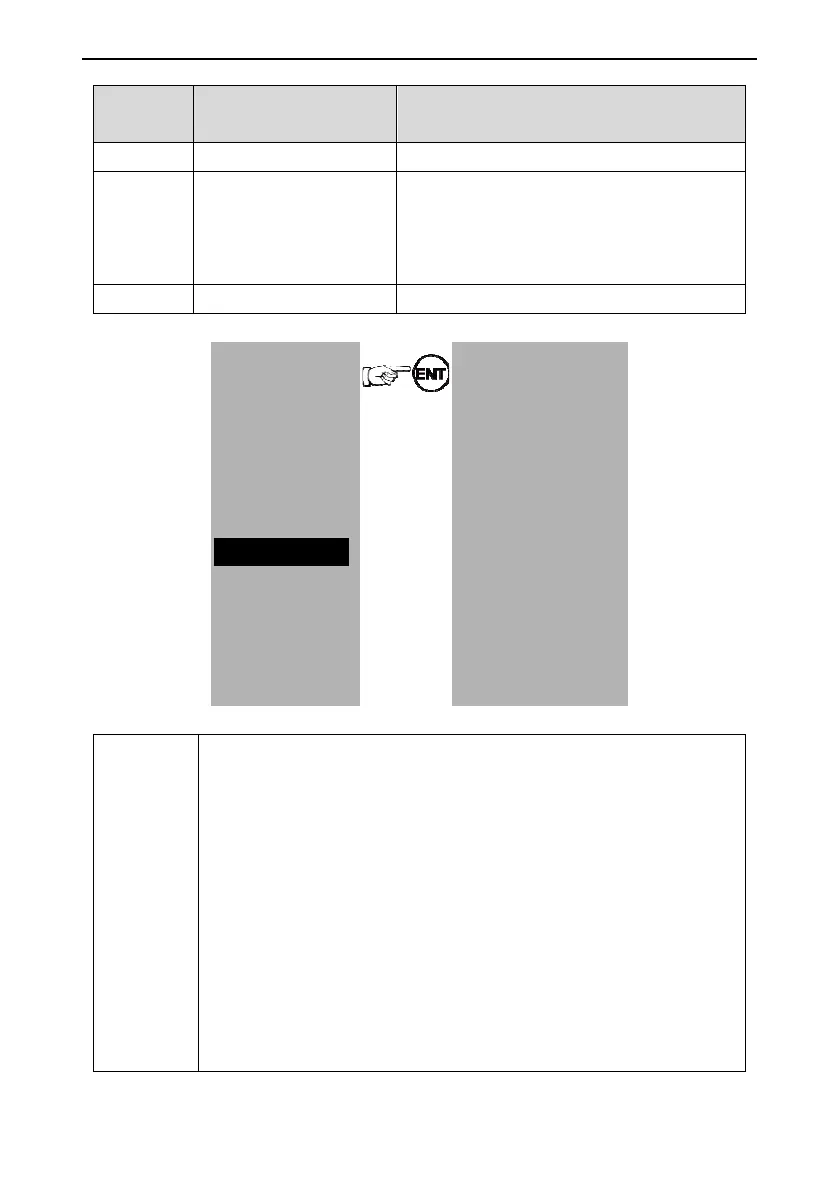

Enter into the main menu-F system autotuning to select motor rotating autotuning.

【main menu】

A system control

B fault record

C language selection

D parameters setting

inquiry

E password setting

F system autotuning

G data management

H system information

【system autotuning】

] hoistway information

autotuning

[2] motor rotating

autotuning

[3] motor static

autotuning

[4] LL weighing

autotuning

[5] FL weighing

autotuning

[6] OL weighing

autotuning

Steps of

rotating

autotuning

1. Check the connection of master UVW, grounding wires, brake and encoder.

2. Ensure the wire rope on the motor is removed before the rotating autotuning

and no damage may occur during rotating.

3. Connect the safety and door lock circuit and check the parameters setting of

master and encoder in the inspection state.

4. Enter into the main menu-F system autotuning-[2] motor rotating autotuning.

Then the operational interface of the manual controller will display “please

confirm the inspection state?”. If select [YES], then the interface will display

“please confirm the autotuning?”. If confirmed, master autotuning will begin.

5. The brake contactor is in the closing state when selecting [YES]. Press the

inspection up button, and then the running contactor will close automatically to

begin the autotuning and the controller will display the motor is autotuning. After

Loading...

Loading...