User manual of EC160 elevator intelligent integrated machine Installation and wiring

30

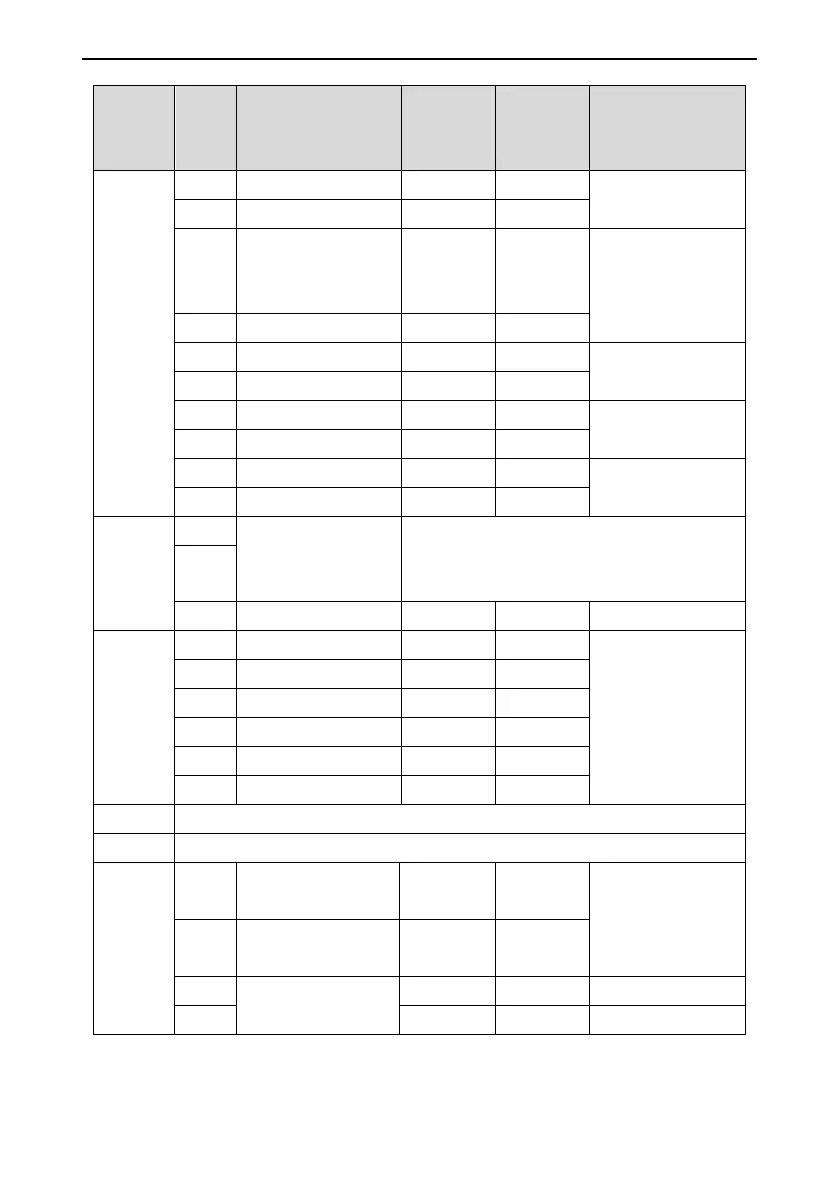

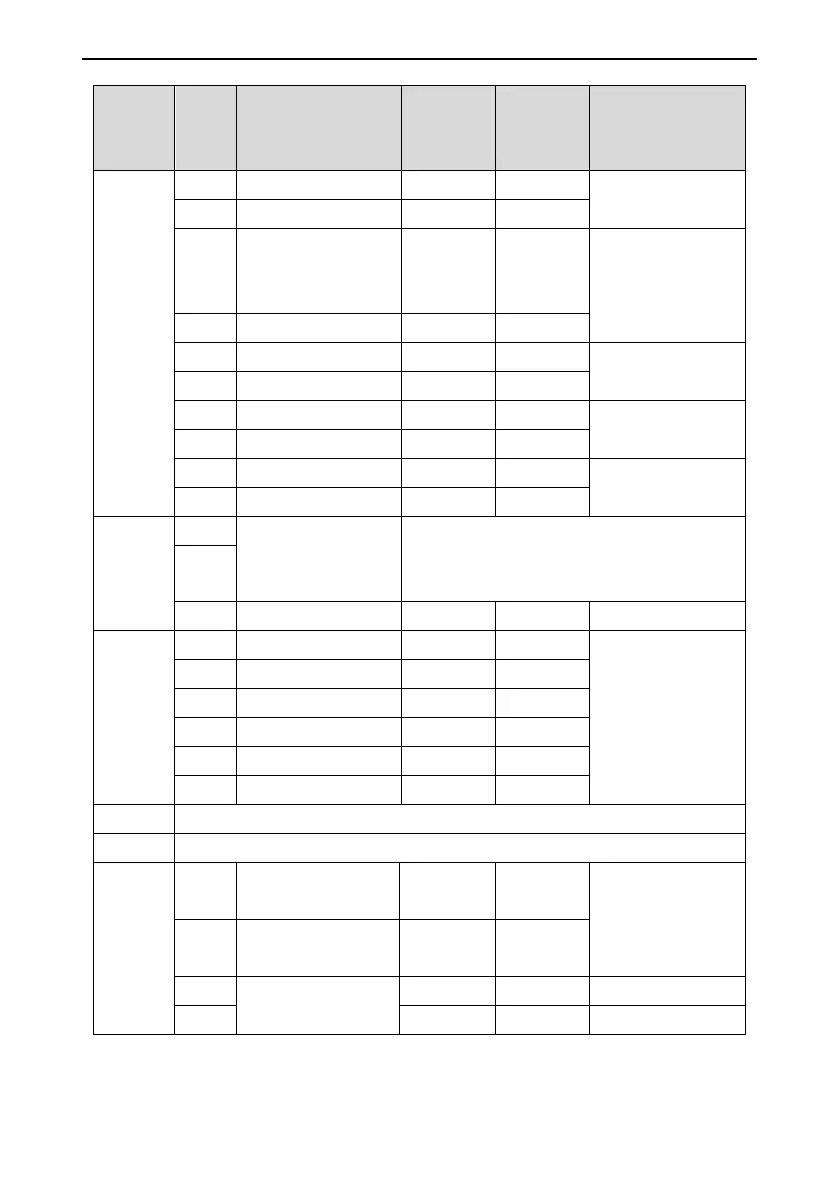

Plug-in

No.

Pin

No.

Terminal definition Code

LED

indicator

code

Remarks

output 250VAC

COM2 Y2 common terminal COM2

Y3

Star-delta contactor

output (synchronous

tractor)

Y3 LED36

Relay NO output 5A,

250VAC

COM3 Y3 common terminal COM3

Y4 FR fire forced output Y4 LED37

Relay NO output 5A,

250VAC

COM4 Y4 common terminal COM4

Y5 MF defined output 1 Y5 LED32

Relay NO output 5A,

250VAC

COM5 Y5 common terminal COM5

Y6 MF defined output 2 Y6 LED33

Relay NO output 5A,

250VAC

COM6 Y6 common terminal COM6

CN8

terminals

1-3

GPRH

CAN2 bus differential

signal

CAN2 communication interface, for parallel

connection and group control: the default terminal

resistance is about 120Ω.

GPRL

COM

CN9

terminals

1-6

12V Encoder power 12V

Encoder terminal of

asynchronous

master, supply

DC12V power

PGM Encoder power 0V

PGA Encoder input A phase

PGB Encoder input B phase

PGM Encoder power 0V

PE Grounding terminal

CN10 Encoder terminal of synchronous master (apply for ECN1387), see wiring diagram.

CN11 Connecting terminal of PG card (apply for ECN1313 encoder or rotary transformer)

CN15

1-4

AI1

Positive analog input

terminal

AI1

Input impedance:

10Ω;

Voltage range: 0~10V

GND

Negative analog input

terminal

GND

485+

RS485 differential

signal

485+ For monitoring

485- 485- For monitoring

Loading...

Loading...