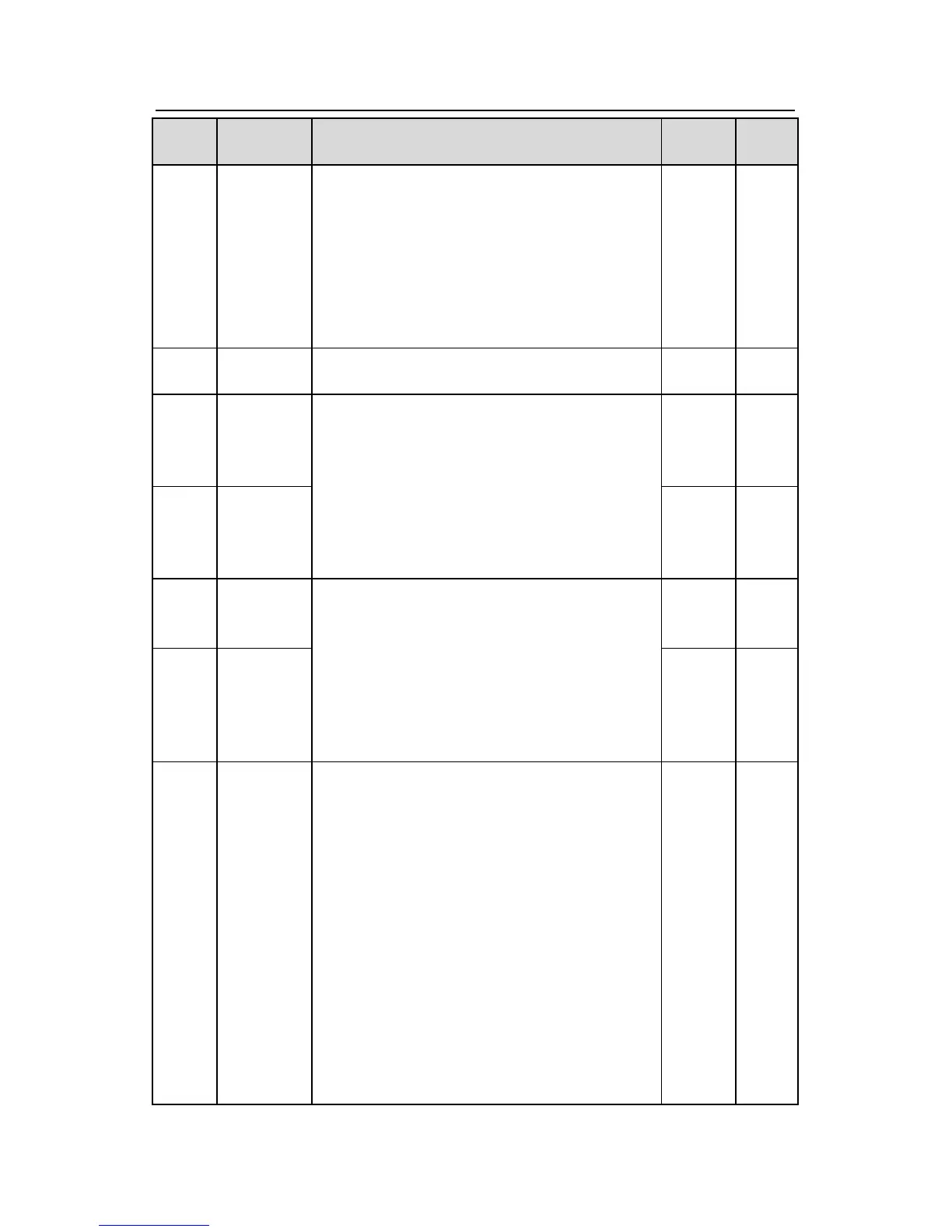

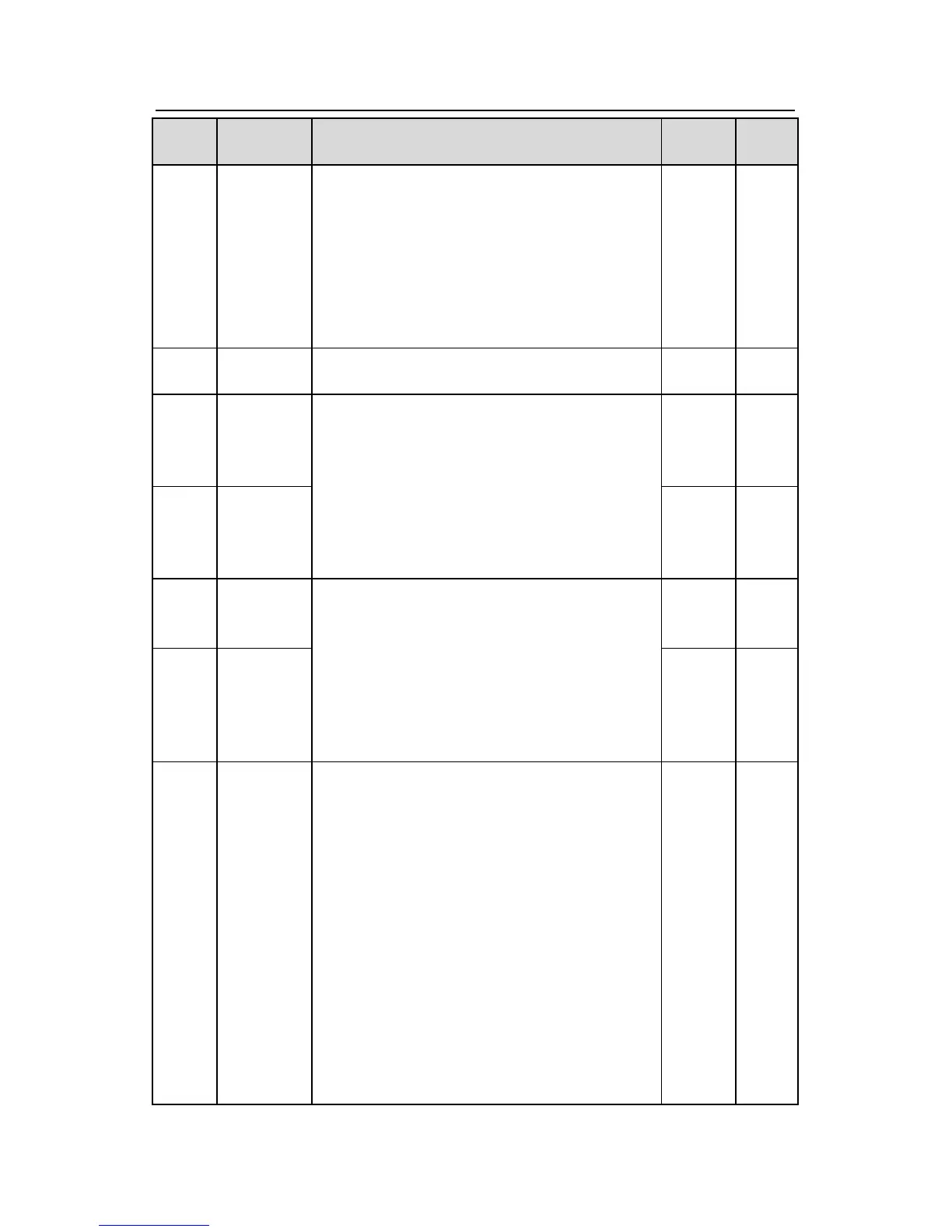

Goodrive200A inverters Function parameters

43

Function

code

Name Detailed instruction of parameters

Default

value

different loads to meet various demands.

The setting range of P03.00:0~200.0

The setting range of P03.01: 0.000~10.000s

The setting range of P03.02:0.00Hz~P03.05

The setting range of P03.03:0~200.0

The setting range of P03.04: 0.000~10.000s

The setting range of P03.05:P03.02~P00.03(the

Max. output frequency)

P03.06

0~8 (corresponds to 0~2

8

/10ms) 0 ○

P03.07

Compensatio

n coefficient

of electro

motion slip

Slip compensation coefficient is used to adjust

the slip frequency of the vector control and

improve the speed control accuracy of the

system. Adjusting the parameter properly can

control the speed steady-state error.

Setting range:50~200%

100%

Compensatio

n coefficient

of braking

slip

100%

Current loop

percentage

coefficient P

Note:

1 These two parameters adjust the PI adjustment

parameter of the current loop which affects the

dynamic response speed and control accuracy

directly. Generally, users do not need to change

the default value.

2 Only apply to SVC control mode 0(P00.00=0).

Setting range:0~65535

1000 ○

P03.10

Current loop

integral

coefficient 1

Torque

setting

method

This parameter is used to enable the torque

control mode, and set the torque.

0:Torque control is invalid

1:Keypad setting torque(P03.12)

2:Analog AI1 setting torque(The inverter( ≤

15kW) can be set by the analog potentiometer on

the keypad and AI1 setting is not available for the

device which is 18.5kW or higer than 18.5kW)

3:Analog AI2 setting torque

4:Analog AI3 setting torque

5:Pulse frequency HDI setting torque

6:Multi-step torque setting

7:MODBUS communication setting torque

8~10:Reserved

Note: Setting modes 2~10, 100% corresponds to

0 ○

Loading...

Loading...