Goodrive10 Series Mini VFD Communication protocol

-101-

7.3.7.2 Examples of writing command 06H

Make the VFD with the address of 03H to run forward. See section 7.3.4.2 “Description of

other function addresses in Modbus”, the address of “Communication-based control

command” is 2000H and forward running is 0001.

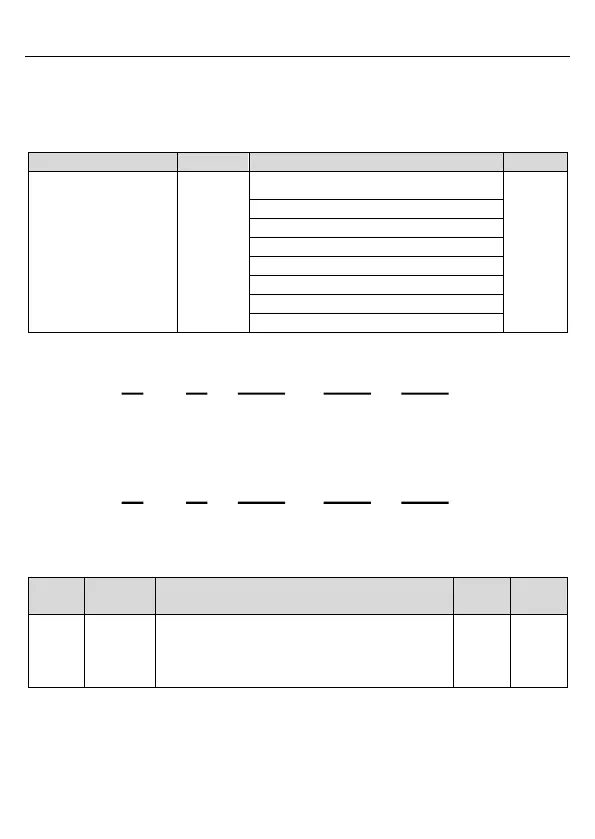

Communication-based

control command

0006H: Coast to stop (emergency stop)

The command sent by the master:

Parameter

address

CRC

check

VFD

address

Write

command

Forward

running

03 06 20 00 00 01 42 28

If the operation is successful, the response may be as below (the same with the command

sent by the master):

Parameter

address

CRC

check

VFD

address

Write

command

Forward

running

03 06 20 00 00 01 42 28

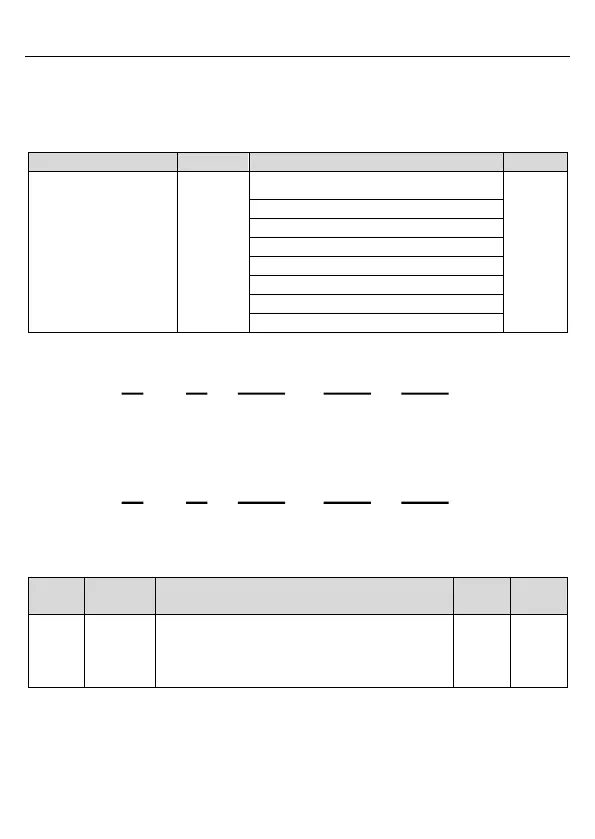

Set max. output frequency of the VFD with the address of 03H as 100Hz.

Used to set max. output frequency of the VFD. It is

the basis of frequency setup and the

acceleration/deceleration.

Setting range: P00.04–400.00Hz

See the figures behind the radix point, the fieldbus ratio value of max. output frequency

(P00.03) is 100. 100Hz timed by 100 is 10000 and the corresponding hex is 2710H.

The command sent by the master:

Loading...

Loading...