Goodrive10 Series Mini VFD Communication protocol

-94-

instructions should be paid attention to when modifying the function code parameters.

EEPROM is stocked frequently, which may shorten the usage time of EEPROM. For

users, some functions are not necessary to be stocked on the communication mode.

The needs can be met on by changing the value in RAM. Changing the MSB of the

function code form 0 to 1 can also realize the function. For example, the function code

P00.07 is not stocked into EEPROM. Only by changing the value in RAM can set the

address to 8007H. This address can only be used in writing RAM other than reading. If

it is used to read, it is an invalid address.

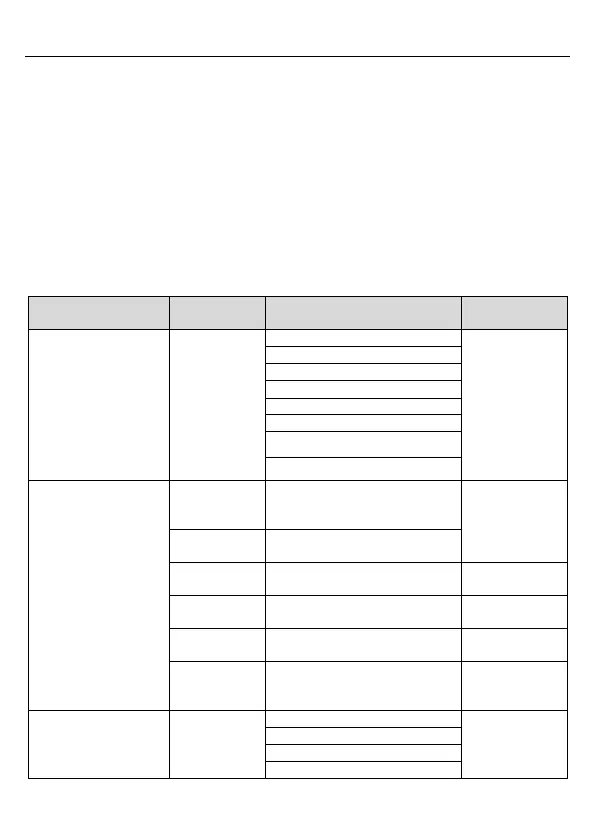

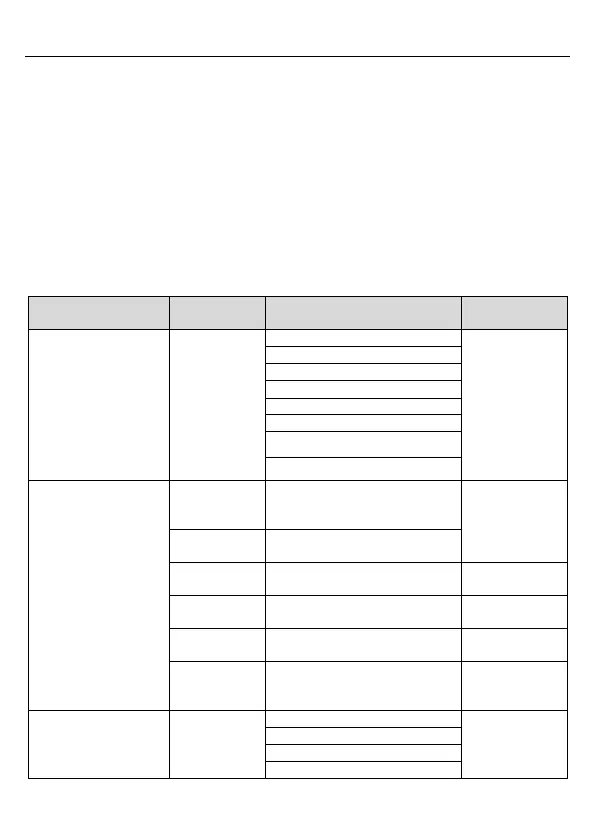

7.3.4.2 Description of other function addresses in Modbus

BIn addition to modifying the parameters of the VFD, the master can also control the VFD,

such as start and stop it, and monitor the operation state of the VFD. The following table

describes other function parameters.

Communication-based

control command

Communication-based

value setting

Communication setting

frequency (0–Fmax (unit:

0.01Hz))

PID reference, range (0–1000,

1000 corresponds to100.0% )

PID feedback, range (0–1000,

1000 corresponds to100.0% )

Virtual input terminal command ,

range: 0x000–0x1FF

Virtual input terminal command ,

range: 0x00–0x0F

AO output setting 1

(-1000–1000, 1000 corresponds

to 100.0%)

Loading...

Loading...