22

Electrical Installation and Wiring

For the following applications additional line reactors are strongly recommended:

• high short circuit currents

• compensation-plants without a coil

• asynchronous motors which are responsible for a voltage drop >20% of the line voltage

EMC Summary

• Install proper grounds according to local codes and regulations

• Do not install the power wires in parallel to control wires

• Use screened control cables

• Connect both ends of the motor wire screen to ground

• Connect only one end of the control wire screen to ground

• Motor wires should be as short as possible

8.3 Recommended Wire Types

For maximum 40º C ambient temperature, recommend use of 75º C wire of the following types: RHW,

THHW, THW, THWN, XHHW, USE, ZW.

8.4 Wiring and Connections

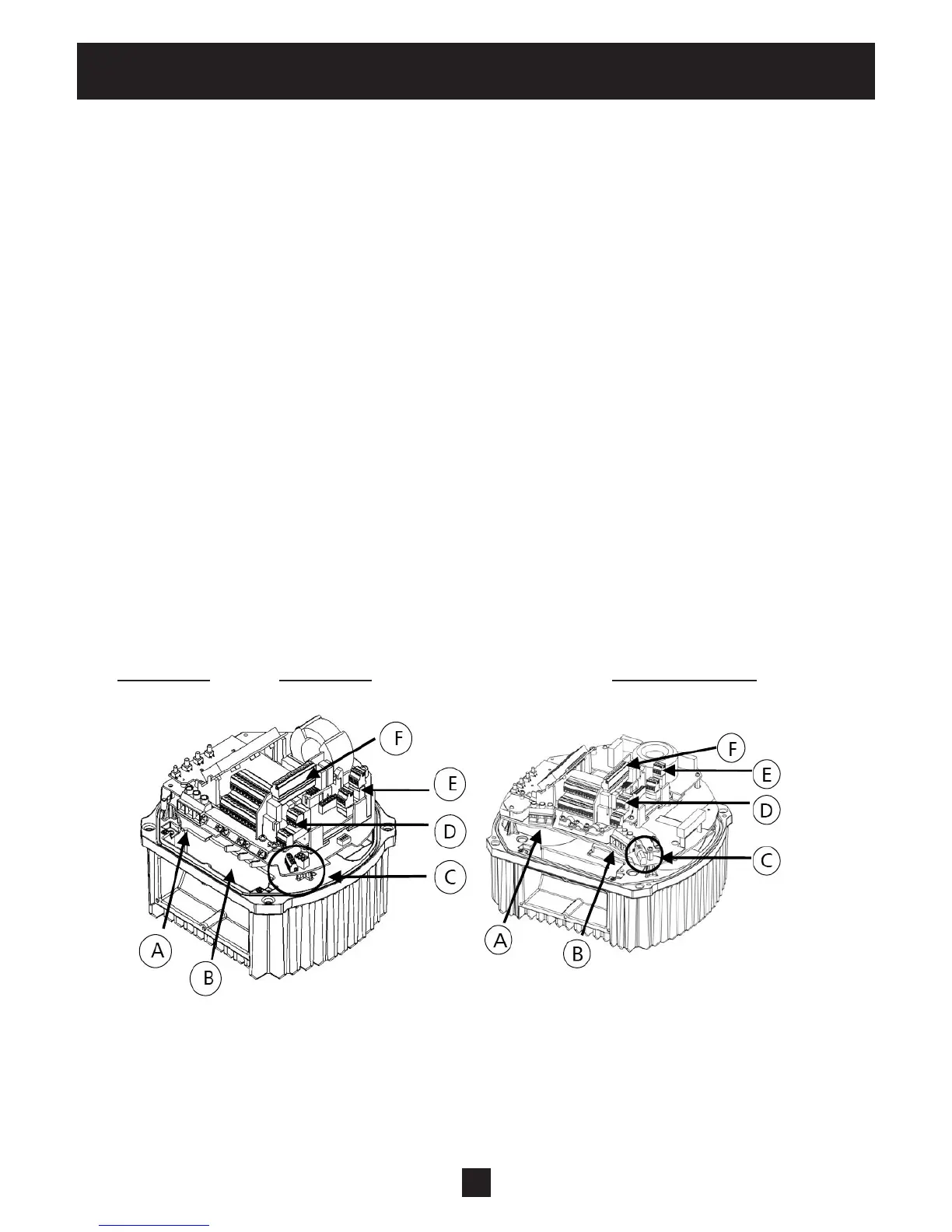

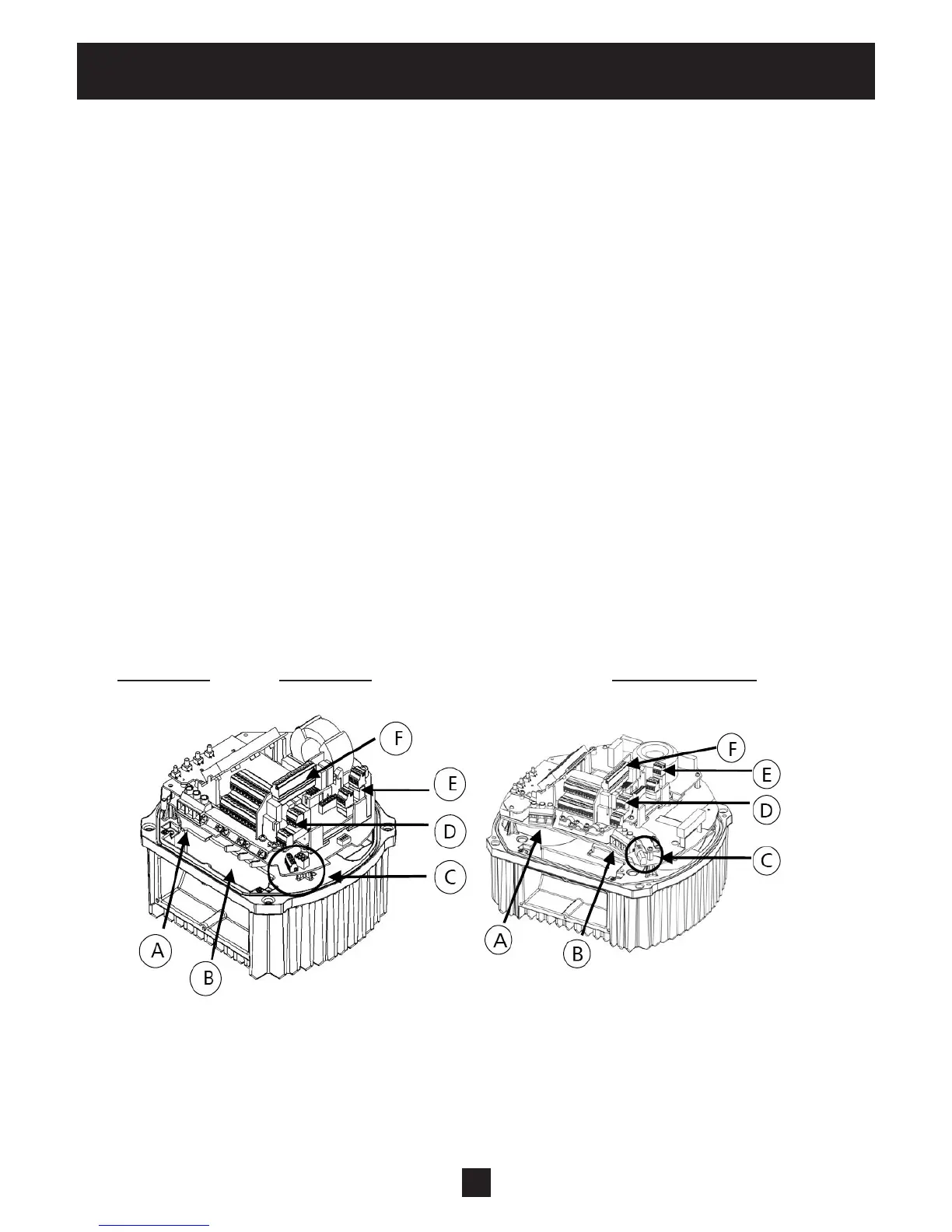

Remove the screws holding the top cover of the HYDROVAR.

Lift off the top cover. The following parts can be seen on a HYDROVAR Master / Single Drive:

1 Ph 2, 3 HP 3 Ph 3, 5 HP 3 Ph 7.5, 10, 15 HP

(A) Power supply (B) Motor connections (C) Terminal block:

- START/STOP

(D) RS-485 Interface (E) Status-Relays - SOLORUN (hand mode)

- User interface - RS-485 Interface

- Internal interface (F) Optional Relay Card

Loading...

Loading...