HYDRAULICS

4181384 First Edition 6-49

6

Disassembly, Inspection, and Assembly

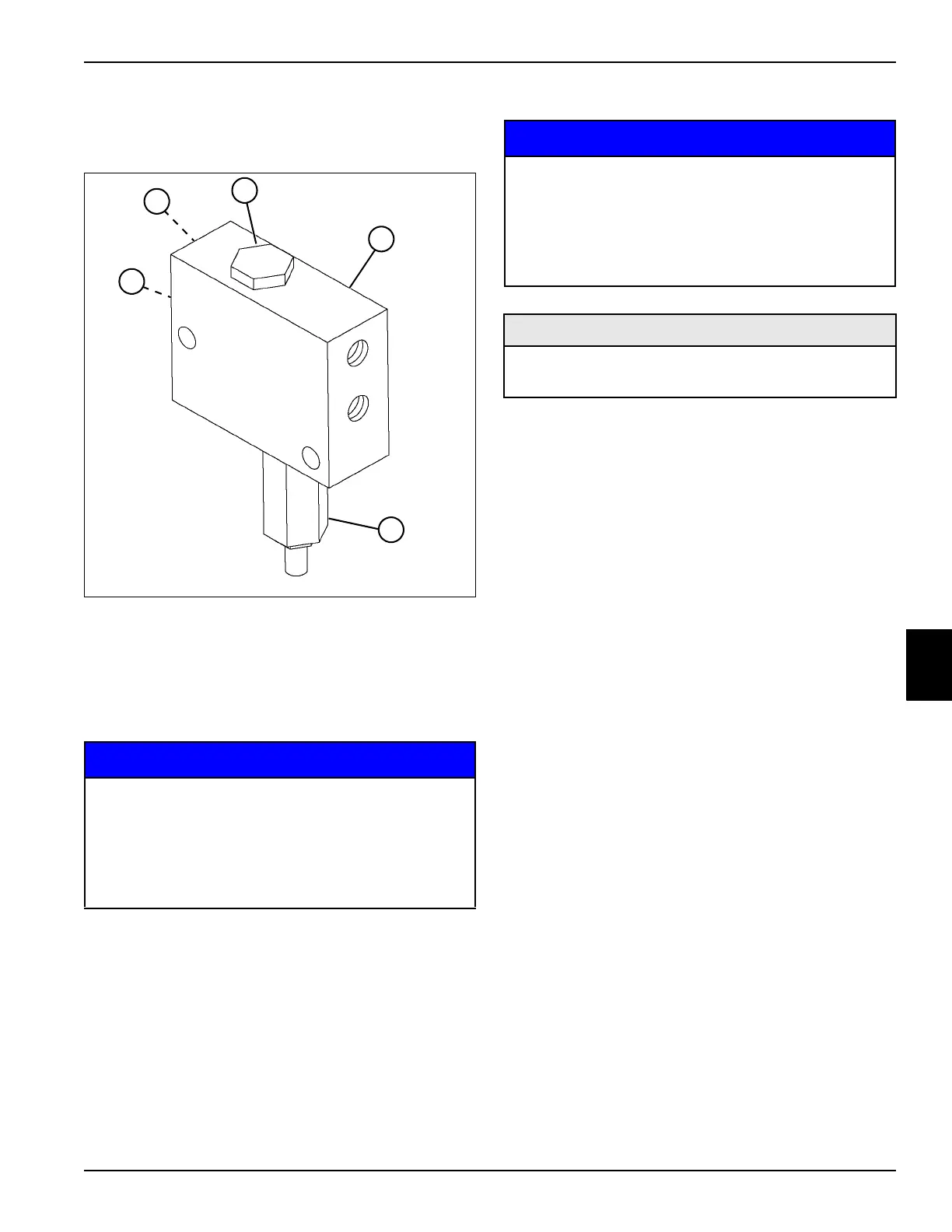

See Figure 6-44.

Figure 6-44

1. Remove, inspect, and replace flushing valve

components as needed.

NOTICE

2. Clean all parts using clean solvent, and dry using

compressed air.

3. Inspect all parts for wear or damage. Replace parts

as needed.

Assembly Notes

NOTICE

• Assemble flushing valve by reversing the order of

removal.

• Lubricate all O-rings prior to assembly.

• Tighten the check valve (2) to 37 lb-ft (50 N·m).

• Tighten sequence valve (4) to 37 lb-ft (50 N·m).

• Tighten M5 x 1.00 diameter orifice plug (5) to 2 lb-ft

(27 lb-in.) (3 N·m).

• Tighten M5 x 0.50 diameter orifice plug (1) to 1.7 lb-ft

(20 lb-in.) (2.5 N·m).

1 Orifice Plug 4 Sequence Valve

2 Check Valve 5 Orifice Plug

3 Flushing Valve Block

It is important that all components are absolutely

clean, as contamination can result in serious

damage and/or improper operation.

Never use shop towels or rags to dry parts after

cleaning, as lint may clog passages. Dry parts

using compressed air.

TN1336

2

4

1

5

3

It is important that all components are absolutely

clean, as contamination can result in serious

damage and/or improper operation.

Never use shop towels or rags to dry parts after

cleaning, as lint may clog passages. Dry parts

using compressed air.

Required Materials

Seal Kit, Sequence Valve (Jacobsen P/N 4137262)

Seal Kit, Check Valve (Jacobsen P/N 4137263)

Loading...

Loading...