13

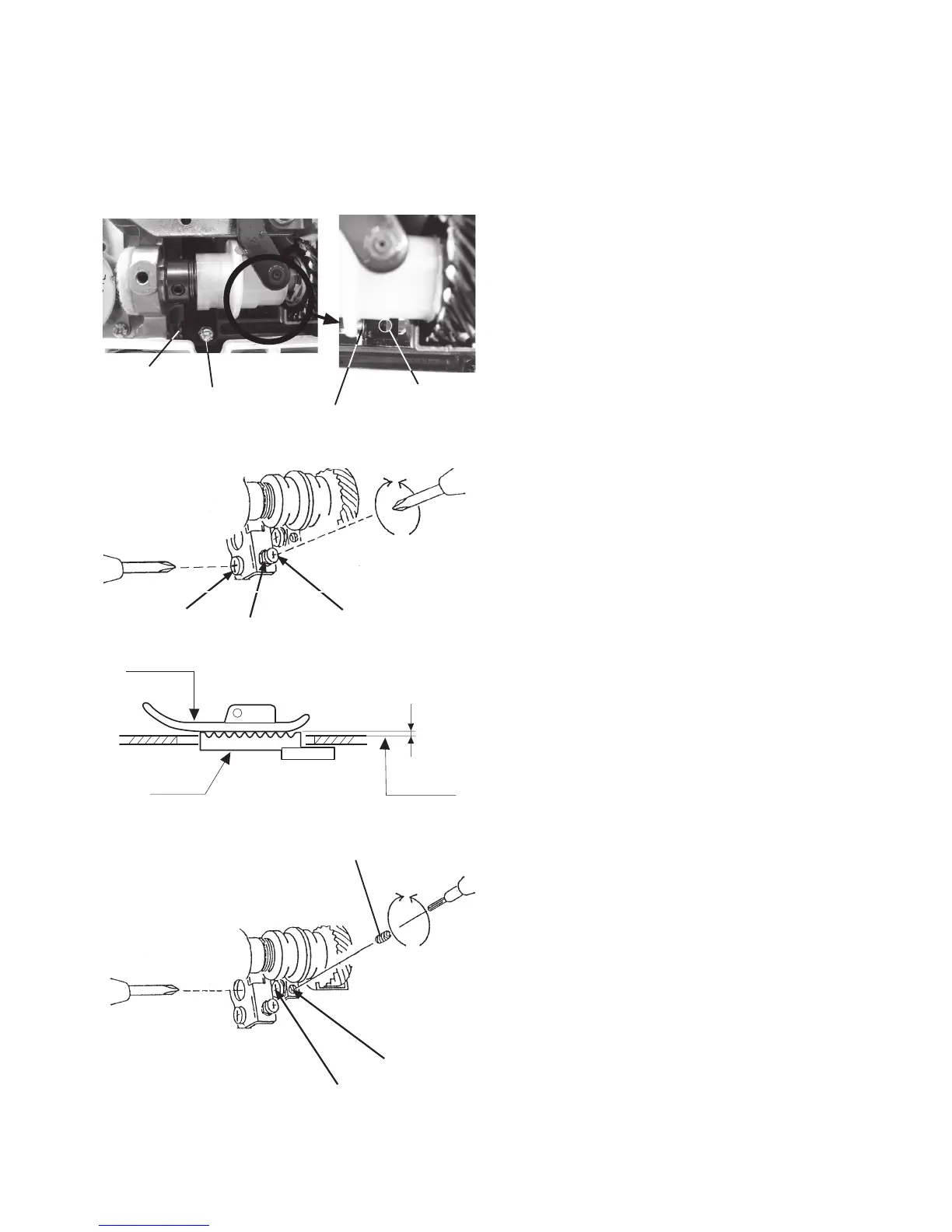

Nut

Setscrew A

Adjusting screw B

Presser foot

0.80 – 0.90 mm

Surface of

needle plate

Feed dog

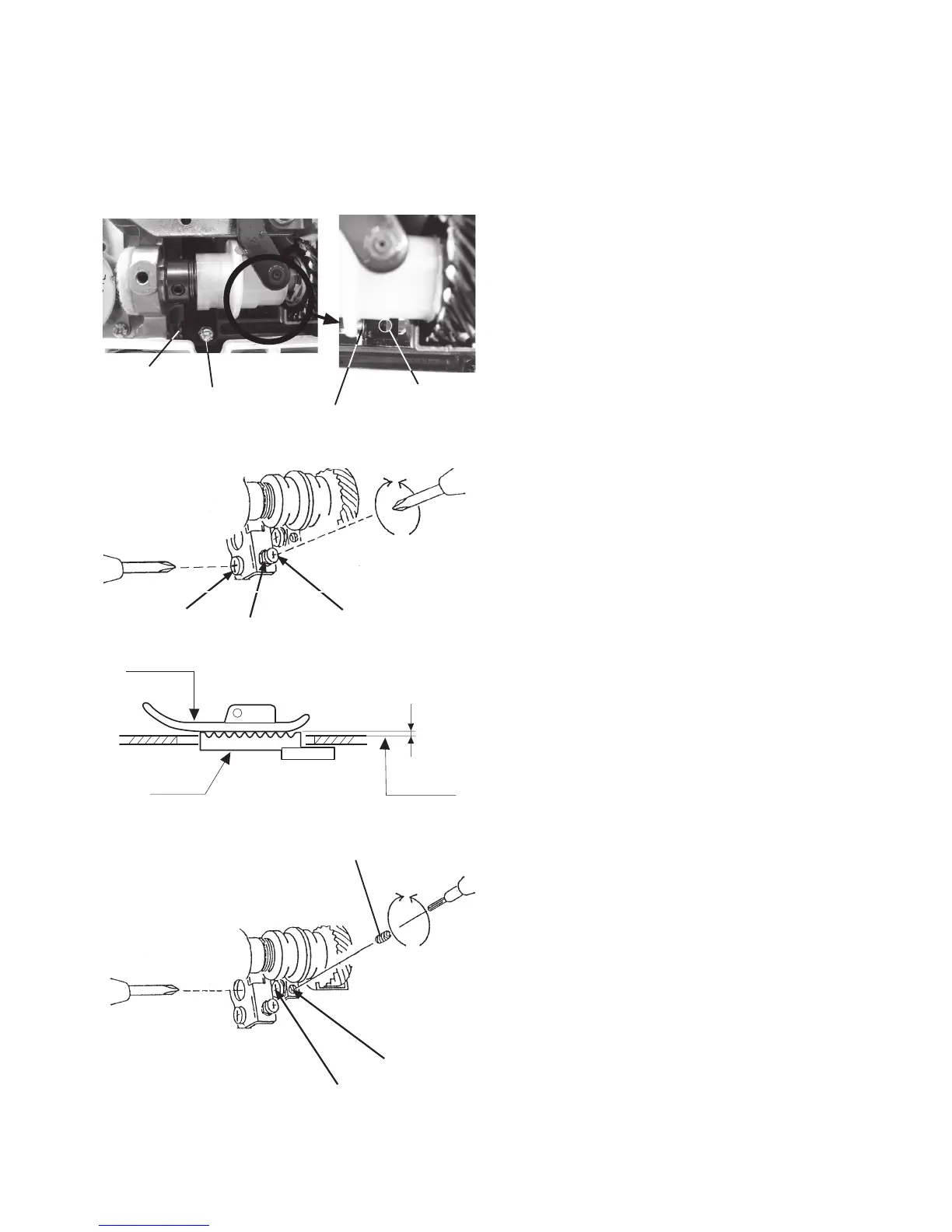

Hexagonal socket screw I

Setscrew D

Threaded hole C

Adjusting screw B

Threaded hole C

Setscrew A

Setscrew D

Mechanical adjustment

Feed dog height

When the foot pressure is set at maximum (AUTO+4) and the presser foot A is lowered, the highest position of the feed

dog should be 0.80 to 0.90 mm from the surface of the needle plate.

1. Attach the zigzag foot A. Remove the bed cover and

base cover (see page 3).

2. Turn the power switch ON. Adjust the foot pressure to

the maximum (AUTO+4) in the ordinary sewing setting

mode. Adjust the stitch length to the maximum (5.0).

3. Press the presser foot lifter button to lower the presser

foot.

4. Turn the handwheel toward you to raise the feed

dog to its highest position.

5. Loosen the setscrew (A).

6. Loosen the nut with a socket wrench.

Turn the adjusting screw and adjust the feed dog hight

to 0.85 mm.

7. Tighten the nut and setscrew (A).

8. Turn the handwheel and check that the feed dog teeth

are pararell with the surface of the needle plate. If not,

follow the adjustment procedure below.

If the feed dog is not parallel to the surface of the needle

plate at its highest position, make the adjustment as

follows:

* For this adjustment, a hexagonal socket screw 4x6, part

No. 000111108 is required.

1. Insert a hexagonal socket screw part No. 000111108

into the threaded hole (C) until it stops (use an Allen

wrench of 2 mm width across ats).

2. Turn the setscrew D (left hand screw) clockwise to

loosen it.

3. Turn the hexagonal socket screw until the feed dog is

parallel with the surface of the needle plate.

4. Tighten the setscrew D by turning it counterclockwise.

5. Remove the hexagonal socket screw.

6. Attach the bed cover and base cover.

After nishing adjustment, return the foot pressure to

AUTO.

Loading...

Loading...