15

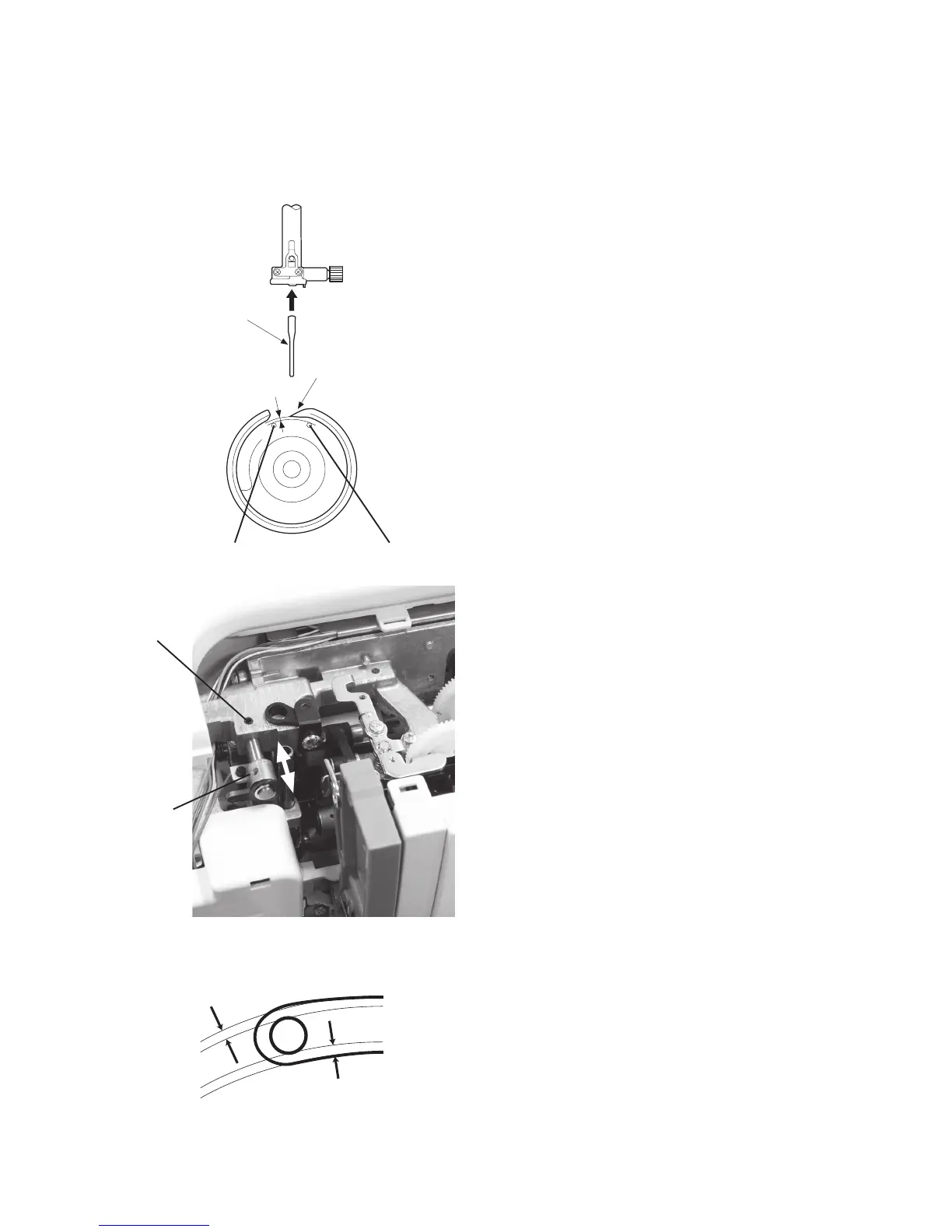

Test pin

Tip of hook

-0.1 to +0.05 mm

Left needle position

Right needle position

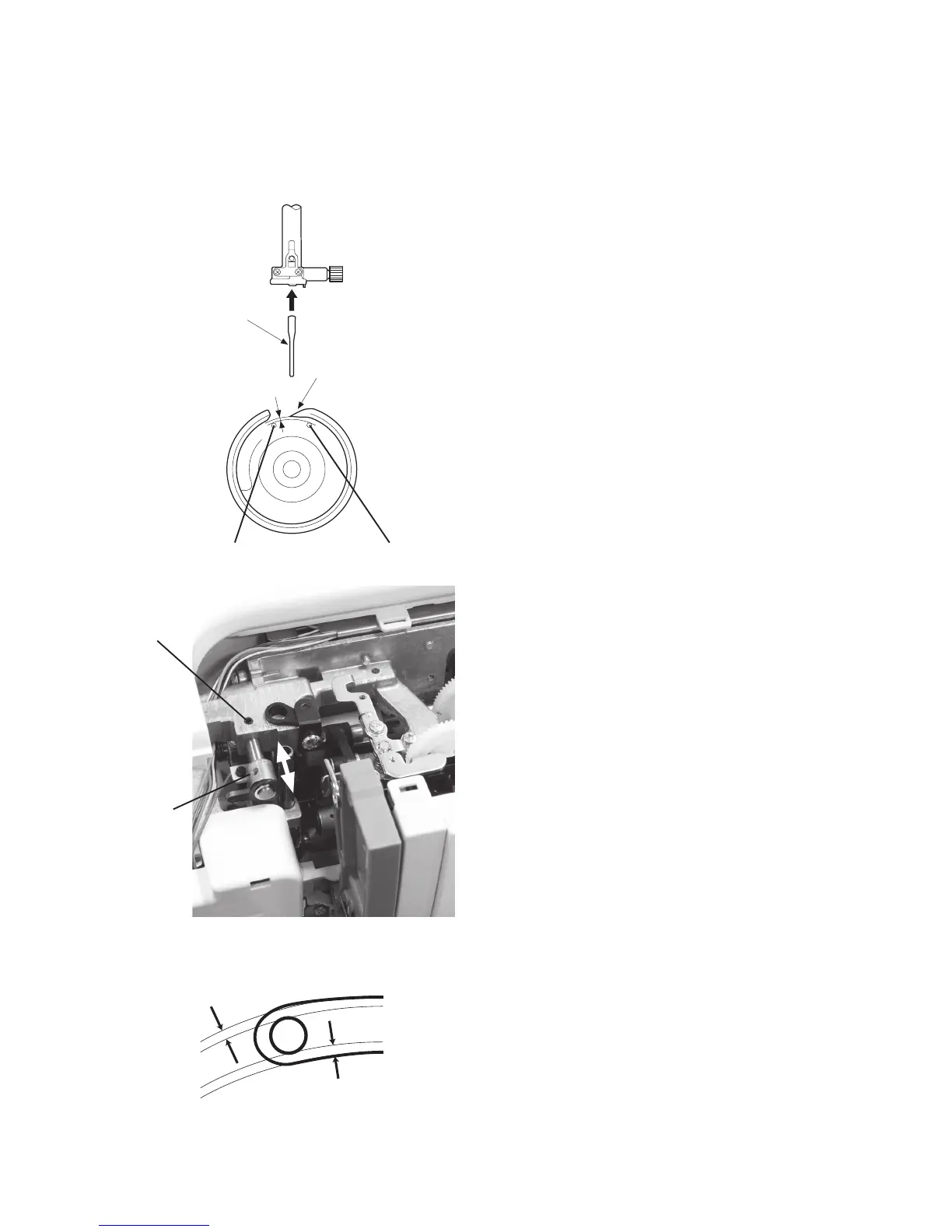

Clearances A and B must be even

A

B

Mechanical adjustment

Clearance between needle and tip of the rotary hook (method 1)

The clearance between the needle and the point of hook should be -0.1 to +0.05 mm.

Needle bar

supporter

Setscrew

1. Remove the top cover (see page 2).

2. Remove the presser foot, the needle plate and the

bobbin holder.

3. Attach the test pin.

4. Turn the power switch ON while pressing the Start/

Stop button and the Reverse stitch button. The LCD

shows the factory setting mode.

Press "Bobbin" key. The machine will set the zigzag

width at maximum.

5. Turn the handwheel toward you until the tip of the

hook comes behind the test pin.

6. Loosen the setscrew (use an Allen wrench of 2 mm

width across ats) and move the needle bar supporter

in the direction of the red arrow so the test pin just

touch the tip of the hook. Tighten the setscrew.

7. Attach the bobbin holder and the needle plate. Check

the needle drop position. The needle drops in the

center of the needle plate hole as shown.

If the clearances A and B are not even, adjust the needle

drop position rst and then adjust the clearance between

the needle and the tip of the hook by the method (2) on

the next page.

Loading...

Loading...