Page 43 of 97

3-MACHINE SIGNALS AND

CONTROLS

______________________________________________________________________________________________

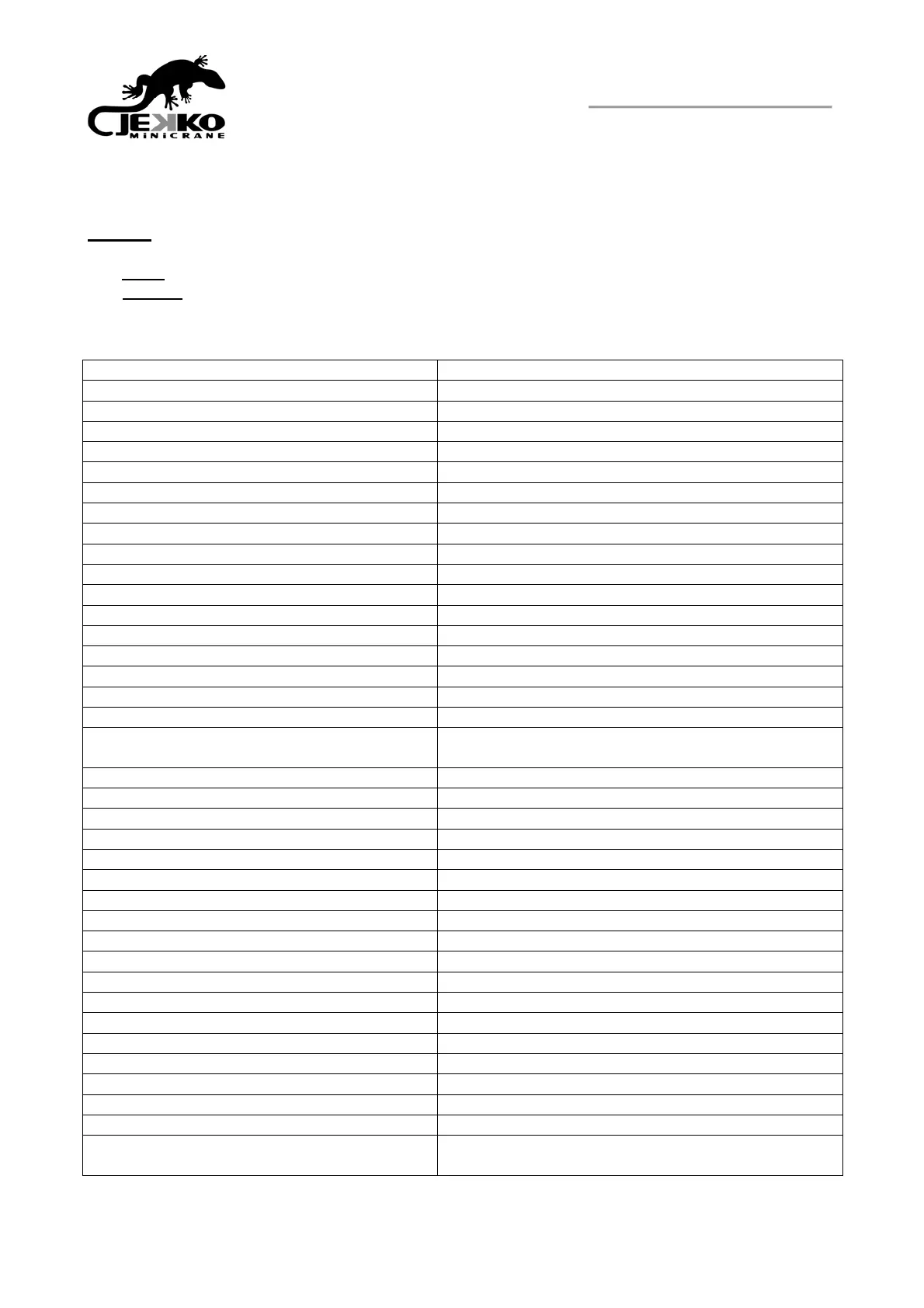

Alarms:

The alarm

code disappears only when the problem is solved

The warning

code appears as a consequence of the wrong move that generated it and disappears

with a 2-second delay in order to suggest the move which is not allowed in that configuration. It

could be present also to give an advertisement about machine functioning. For informations se the

following table and the label present on the machine.

ALARMS

CTION

1 alarm E2PROM HEAD → 1° Check fuses >2°Call service

2 pressure transducer disconnected → Check pressure transducer wiring

3 pressure transducer short-circuited → 1° Check fuses >2°Replace it

4 jib pressure transducer disconnected → Check jib pressure transducer wiring

5 jib pressure transducer short-circuited → 1° Check fuses >2°Replace it

6 winch strain gauge disconnected → Check strain gauge wiring

7 winch strain gauge short-circuited → 1° Check fuses >2°Replace it

8 angle sensor disconnected → Check wiring

9 angle sensor short-circuited → 1° Check fuses >2°Replace it

12 angle sensor disconnected → Check wiring

13 angle sensor short-circuited → 1° Check fuses >2°Replace it

14 angle sensor wrong value → Make calibration

15 Hydraulic Jib angle sensor disconnected → Check wiring

16 Hydraulic Jib angle sensor short-circuited → 1° Check fuses >2°Replace it

30-35 timeout (1-2-3-4-5-6) CANBUS ARM → 1° Check fuses >2°Call service

WARNINGS

CTION

10 local emergency held down → Reset the machine emergency push button

11 remote emergency held down → Reset the radio remote control emergency push

button

40-45 maintenance alarm → Carry out scheduled maintenance

51 block due to max pressure → Activate allowed function by the machine

52 block due to min pressure → Lift the boom

53 block due to max load → Lay the load to the ground or change n° of rope

54 block due to rope up → Unwind the rope or telescope in

55 block due to rope down → Wind the rope

56 block due to machine instability SPD360 → Activate allowed function by the machine

57 clockwise slewing block SPD265 → Turn the boom to the opposite sector

58 counterclockwise slewing block SPD265 → Turn the boom to the opposite sector

59 block due to pressure transducer alarm → Check and/or replace for probable failure

60 block due to jib pressure transducer alarm → Check and/or replace for probable failure

61 block due to winch strain gauge alarm → Check and/or replace for probable failure

62 block due to angle sensor alarm → Check and/or replace for probable failure

63 block due to anticollision → Lower the boom

64 block due to global safety system → 1° Check fuses >2°Call service

65 block due to max angle → Lower the boom

66 slowing down because of the anticollision → No action, safety system

67 slowing down because of the max angle → No action, safety system

68 block of mechanical jib → You are not on a correct jib lifting area, see

lifting diagram!

Loading...

Loading...