51

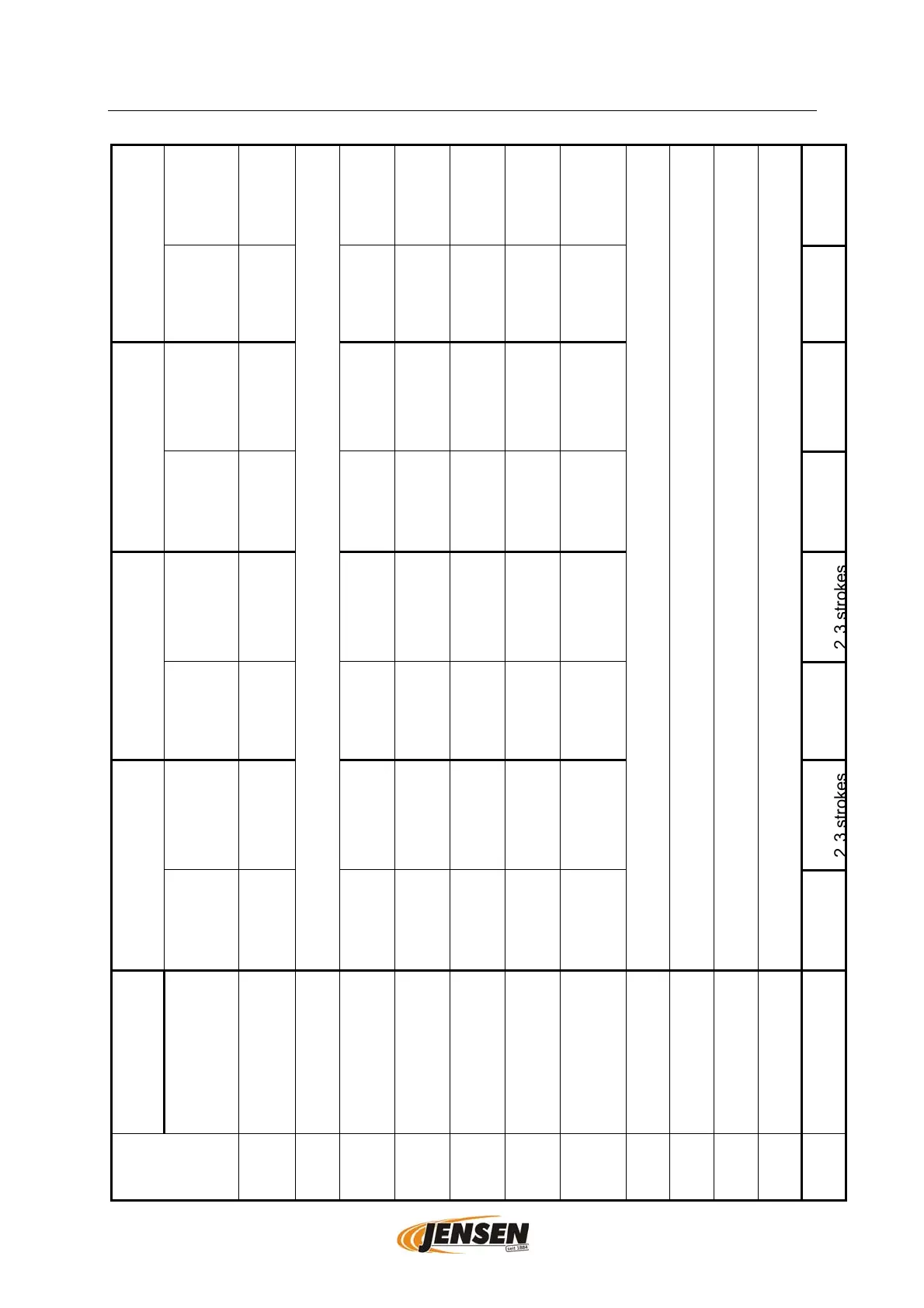

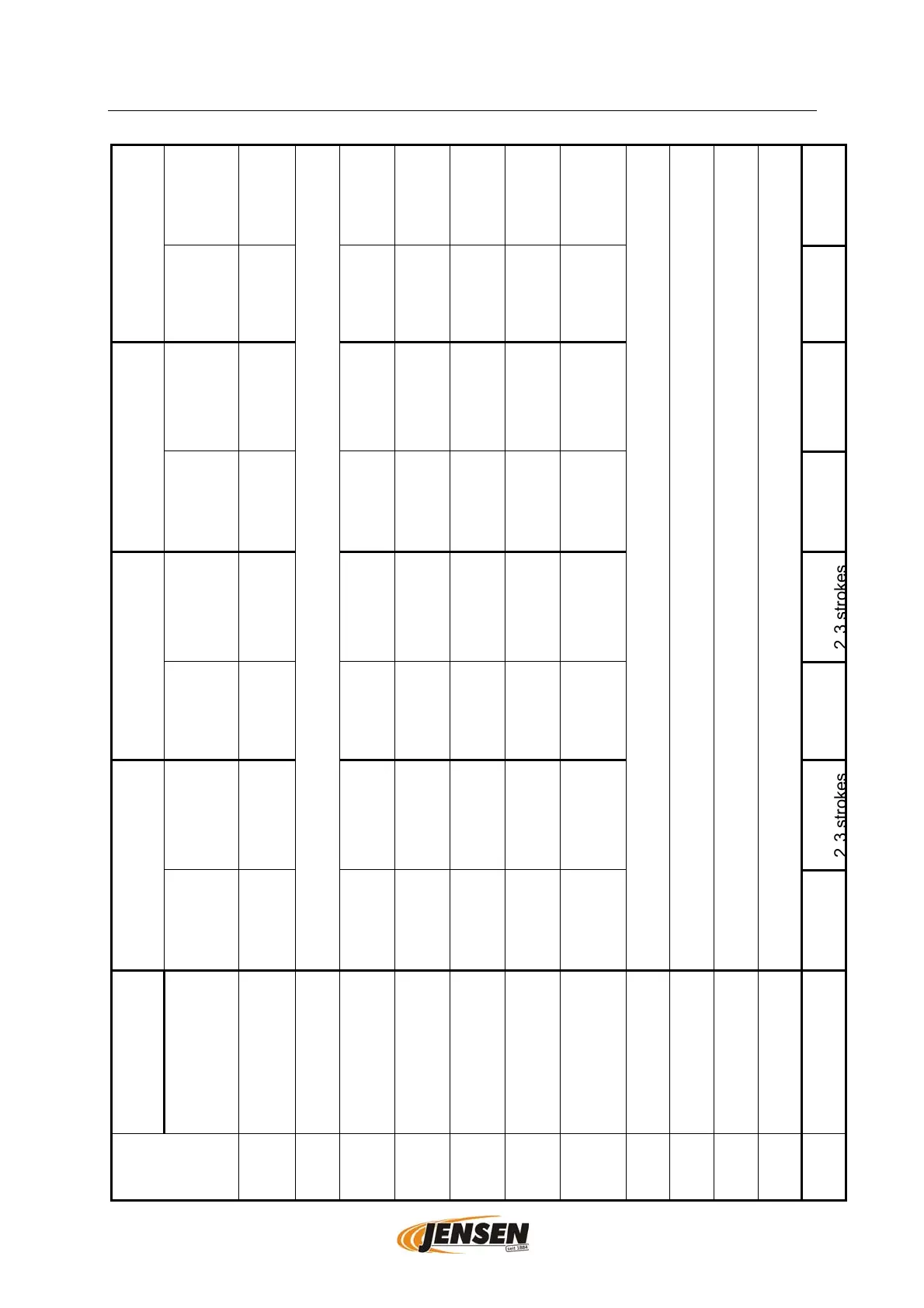

6. Maintenance

6.3.1. Synoptical table: lubrication instructions for the 8-hours shift

A530 / A540 / 550

interval,

grease gun

strokes

monthly,

2-3 strokes

check the oil level weekly at the gauge-glass

weekly,

2-3 strokes

-

maintenance

free

daily,

2-3 strokes

every 14

days

2-3 strokes

monthly until lube spills out of the gaps

see manual of chassis/towing bar + axels

see manual of the PTO shaft

Grease conveyor weekly on both sides with chain lube (recommendation: OKS 451).

-

number of

lubrication

points

2

1/3/3

-

1

1

1/2/2

-

A425 / 430

interval,

grease gun

strokes

monthly,

2-3 strokes

weekly,

2-3 strokes

-

maintenance

free

daily,

2-3 strokes

every 14 days

2-3 strokes

-

number of

lubrication

points

2

3

-

2

1

2

-

A328 / 340

interval,

grease gun

strokes

maintenance

free

weekly,

2-3 strokes

weekly,

2-3 strokes

maintenance

free

daily,

2-3 strokes

every 14 days

2-3 strokes

Weekly,

-

number of

lubrication

points

2

4

2

2

2

2

1

A141 / 041 / A231 / 240

interval,

grease gun

strokes

monthly,

3-4 strokes

every 2 days,

2-3 strokes

every 2 days,

2-3 strokes

maintenance

free

daily,

2-3 strokes

weekly,

2-3 strokes

Weekly,

-

number of

lubrication

points

2

4

2

2

2

2

1

machine type

naming

main bearing of the

knife disk

gear box

joints of the cardan

shaft

sliding tubes of the

cardan shaft

bearing of the

upper roller

guidance of the

square bearing

bearing of the

lower roller

swivel ring frame

chassis (optional)

PTO shaft

conveyor (optional)

Swivel ring ejector

Picture

No:

1

2

3

4

5

6

7

-

-

-

-

-

Loading...

Loading...