75

6. Maintenance

6.14. Chassis

Check tire pressure and wheel bolts regularly. Further information can be found in the

chassis manual in the appendix.

6.15. Engine

Maintenance has to follow the engine manufacturer specifications.

Damage affected due to dust are not covered by the warranty!

6.16. PTO shaft

Maintenance of the PTO shaft has to follow the PTO shaft manufacturer specifications.

Do not use the machine with damaged PTO shafts!

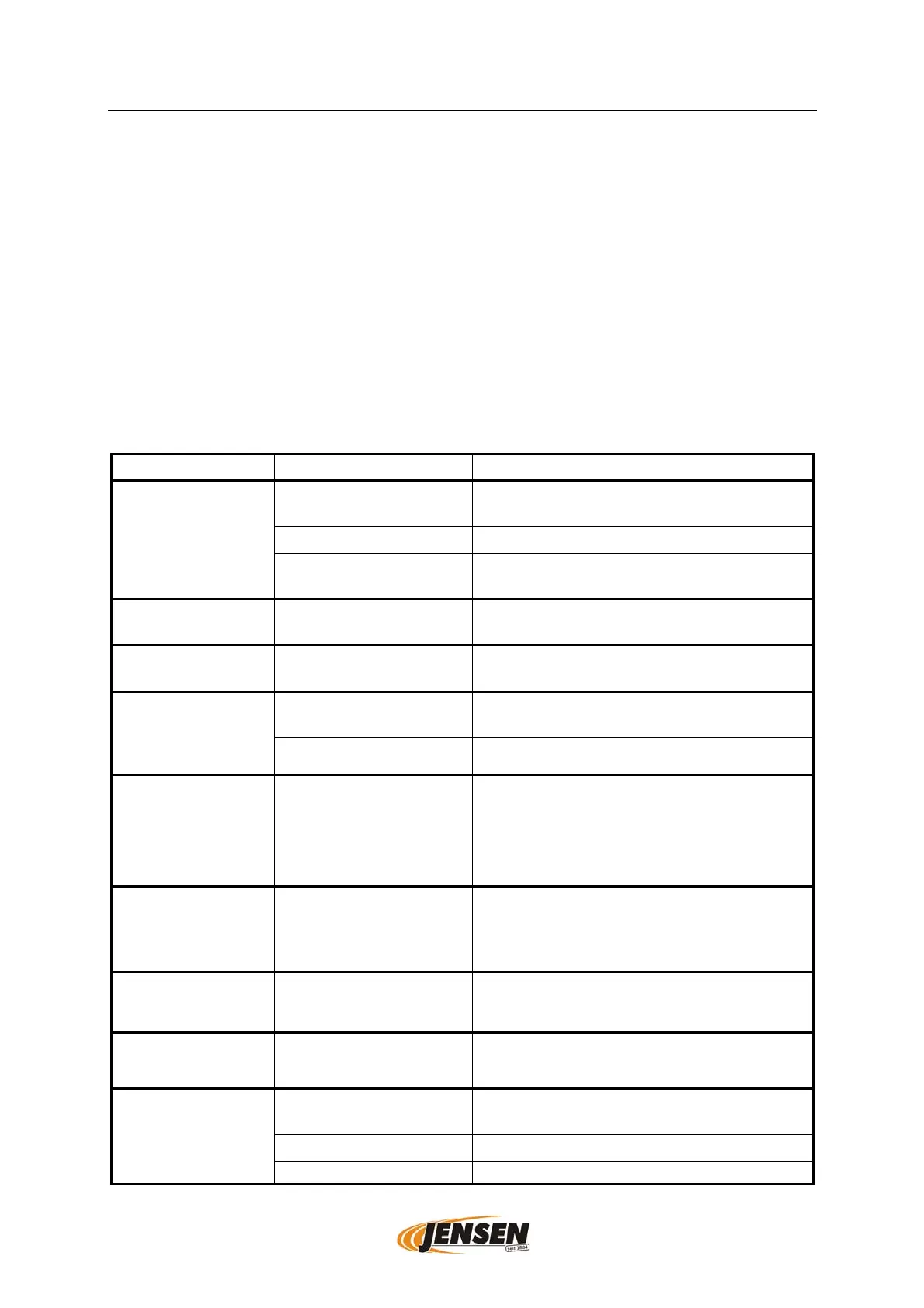

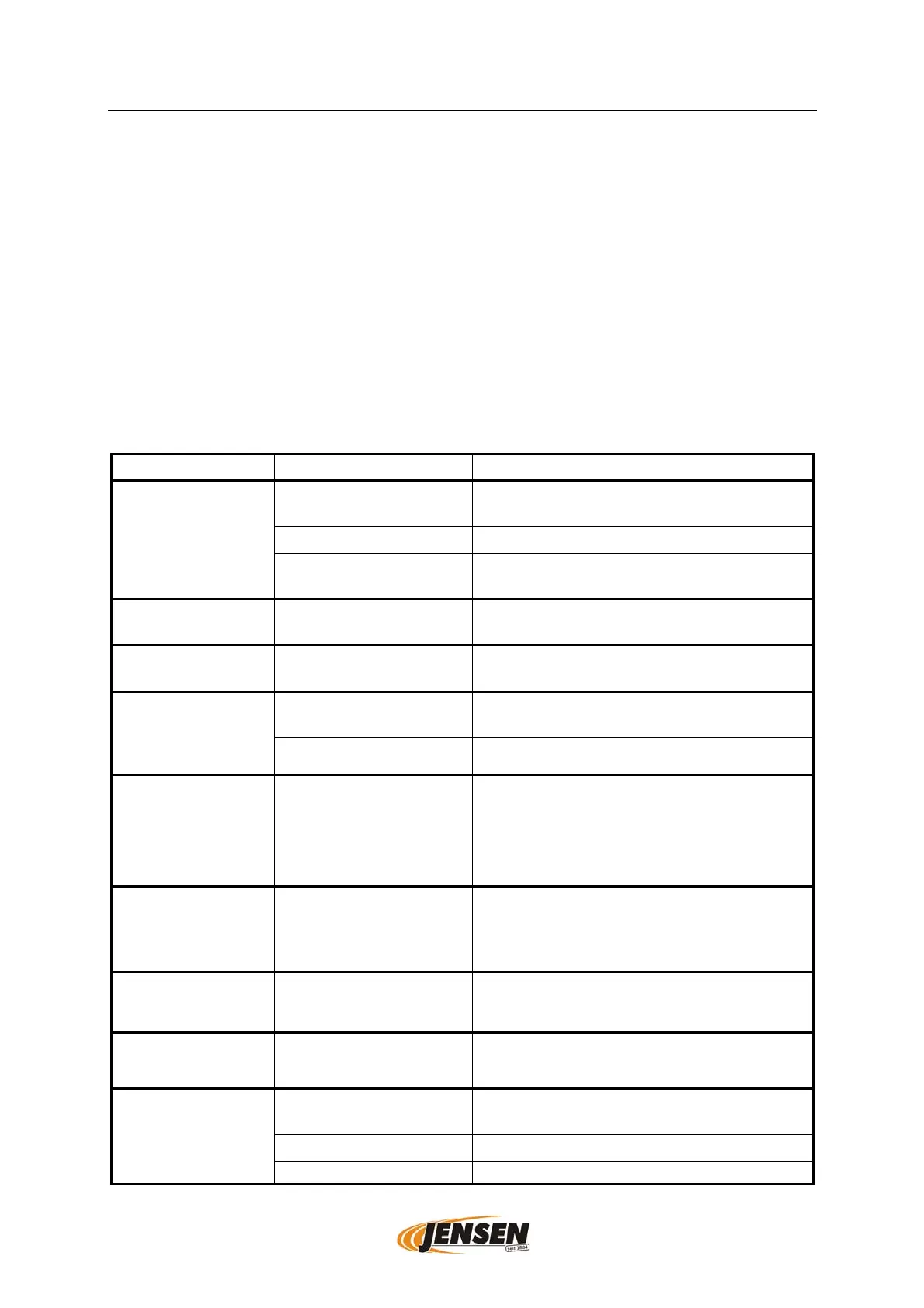

6.17. Troubleshooting

symptom potential cause corrective

woodchips are

frayed, no plane cut

Knife is blunt.

Counter-knife is blunt

Check cutting tools, re-sharpen or replace

knives if necessary.

Knife is too thin Use original knife spacers.

knife disk has shifted on

main shaft

Works on the main shaft should only be

performed by an authorized service center!

rubber smell slipping drive belts, low

belt tension

Check belt tension.

turning infeed rollers

do not feed

tooth work of the rollers is

blunt

Re-grinding of the rollers should only be

performed by an authorized service center!

infeed rollers do not

infeed or barely

infeed

hydraulic oil filter blocked check oil level

change oil filter

hydraulic system failure Repair should only be performed by an

authorized service center!

machine does not

start up

Piece of wood is blocking

the knife disk.

Turn off machine. Remove wood with a proper

device.

Hint: This blockade can be avoided when re-

starting the machine just before the stop of the

knife disk to throw out the wood.

blockade of the

infeed rollers

dimensions of the infeded

material are too big

Shut down machine, open ejector cap. Lock

knife disk. Remove pressure bar located above

the infeed rollers. Turn rollers backwards.

Remove material.

Safety bar does not

change over properly

Worn out friction washer

at the mount of the bar

cause play of the bar.

Adjust the counter nut of the safety bar.

Measured value of

the hydraulic

pressure is too hi

h

Different reasons

possible.

Consult authorized service center!

Measured value of

the hydraulic

pressure is too low

hydraulic pump sucks in

air

Check the condition of the hydraulic system

and for leaks.

hydraulic oil filter blocked Check oil filter and replace if necessary.

oil level is too low Check oil level and refill if necessary.

Loading...

Loading...