JPK Instruments NanoWizard

®

Handbook Version 2.2a

15

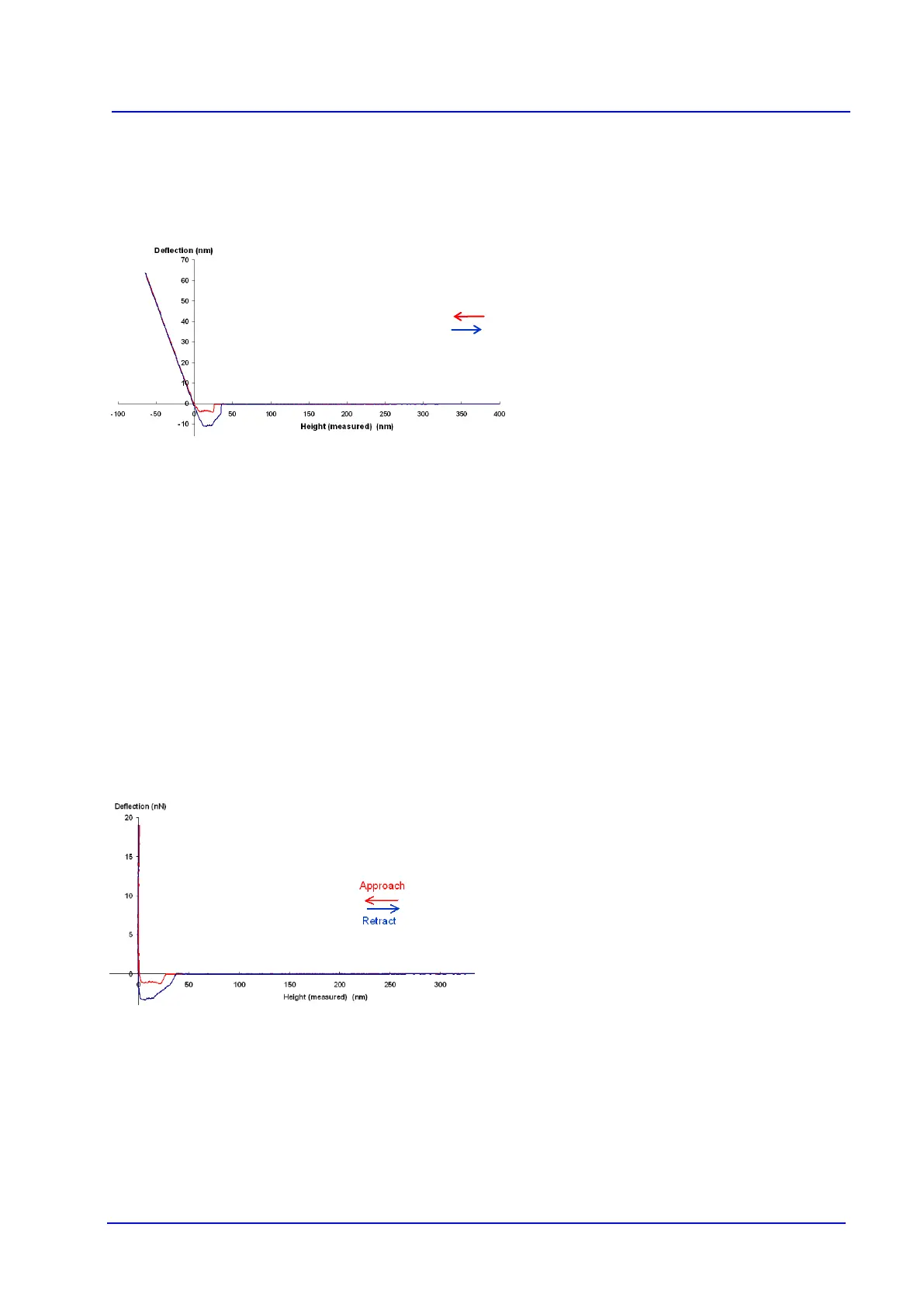

The other linear region, on the left hand side of the plot, is where the tip is resting

on the surface. If the surface is not compressed by the cantilever forces, then the

change in the piezo he

ight (known from the height calibration in nm) is equal to the

cantilever deflection (measured from the photodiode in Volts).

The sensitivity is the conversion

factor (nm true deflection per Volt

measured deflection) needed to

convert the photodiode deflec

tion

into units of length.

The example from above has been

shifted here to give a zero baseline.

The sensitivity (measured from the

curve above as 22 nm/V) has been

used to convert the deflection into

units of length (nm).

The deflection values here a

re now

ready to be converted to units of

Force (N).

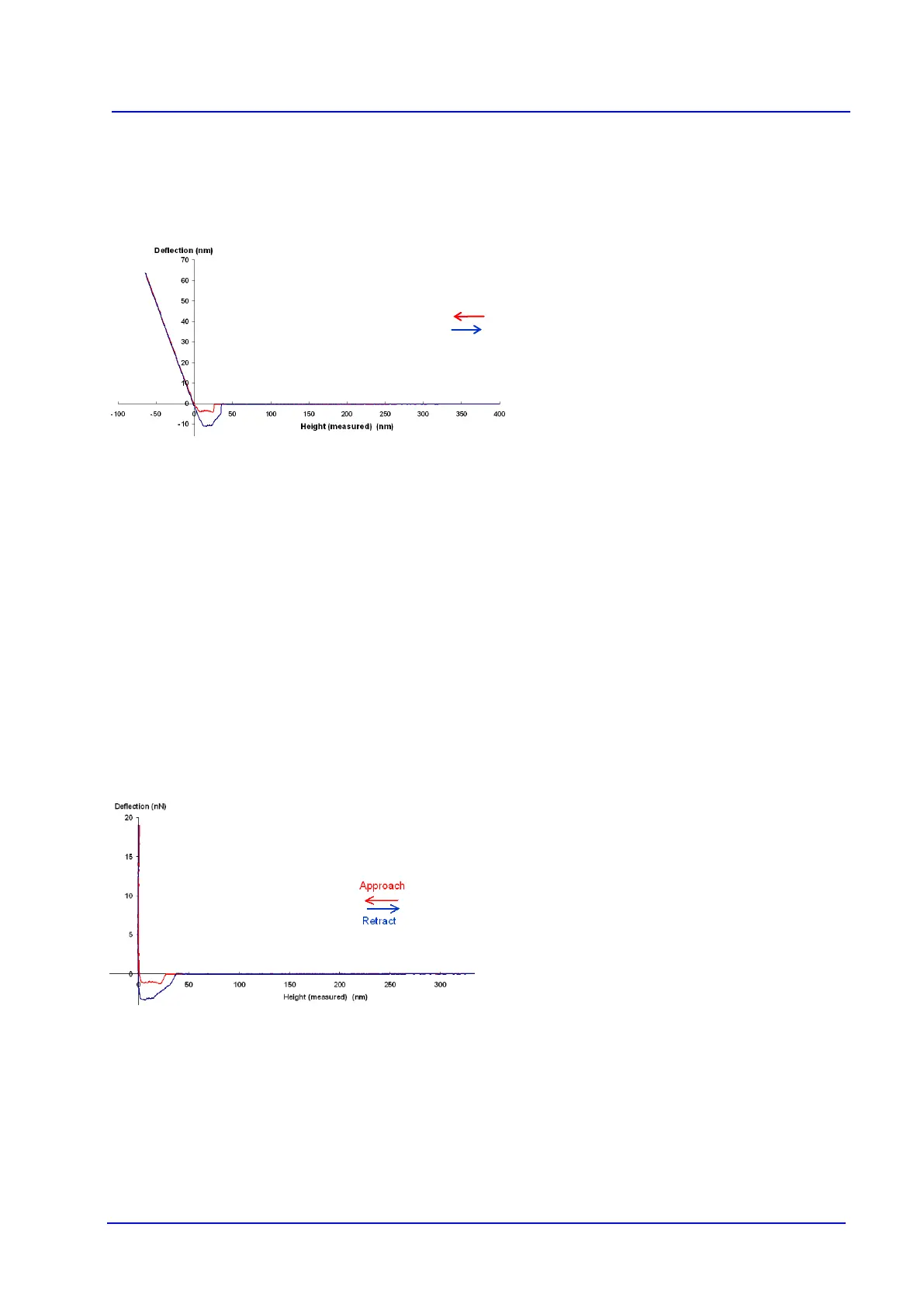

Correction of the height for the cantilever deflection

The plot so far has used an x-

axis of the cantilever height directly

measured from the piezo position. For quantitative analysis of indentation

or

stretching, however, the cantilever is obviously deflected from its

equilibrium position. The deflection should be taken into account to extract

the true tip position relative to the surface. The deflection can then be

plotted against the tip-sample sepa

ration, rather than the piezo height.

Now that the deflection is in units of length, it can be subtracted from the

piezo height at each point to correct for the tip position.

After the sensitivity conversion, the straight line part of the repulsive

int

eraction (left hand side of the curve above) has a gradient of 1, since this

is the basis of the sensitivity calculation. Once the height scale is

corrected, this becomes a vertical line (as seen in the curve below). This is

because the tip-sample separa

tion remains constant at zero, and the action

of the piezo movement merely increases or decreases the force.

The example from above has had

the x-

axis corrected for the tip

deflection. The x-

true tip-sample se

paration, rather

than the piezo height measured

directly.

For quantitative force measurement, the spring constant of the cantilever must be

calibrated, so that the nanometers deflection of the cantilever can be converted into

actual force values. There ar

e various different ways of calibrating spring constants

of cantilevers, depending on the equipment that is available. See Section 4.5

more details. The example above has had the deflection multiplied by

the spring

constant to express the deflection as a force and would now be ready for analysis.

Retract

Approach

Loading...

Loading...