4-1

4-2

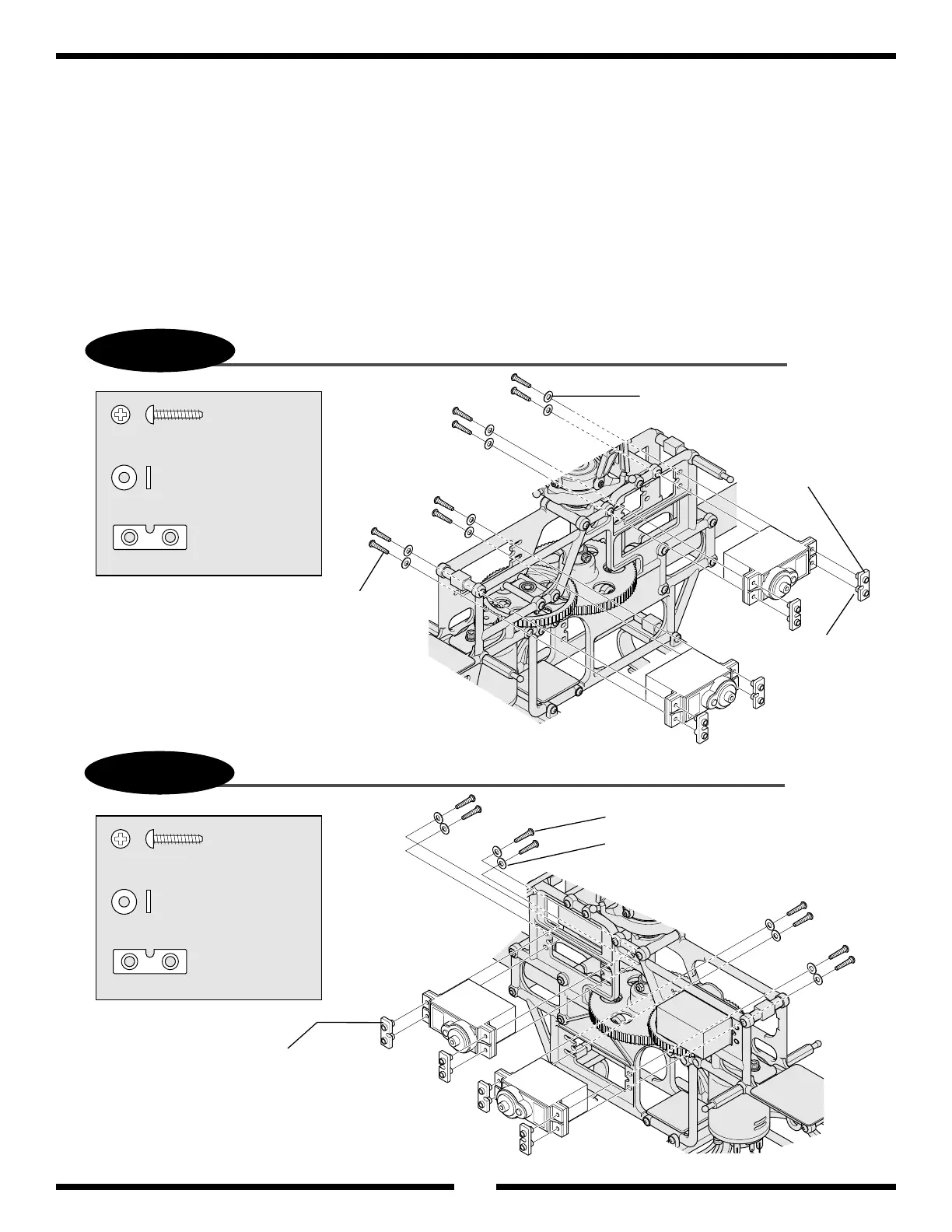

........................8 pcs

2.6 x 12 mm Self Tapping Screw

.......................................... 8 pcs

2.6 mm Flat Washer

..................... ........ 4pcs

Servo Mounting Plate

2.6 mm Flat Washer (8)

Servo Mounting Plate (4)

Long Flange

towards servo

2.6 x 12 mm Self Tapping Screw (8)

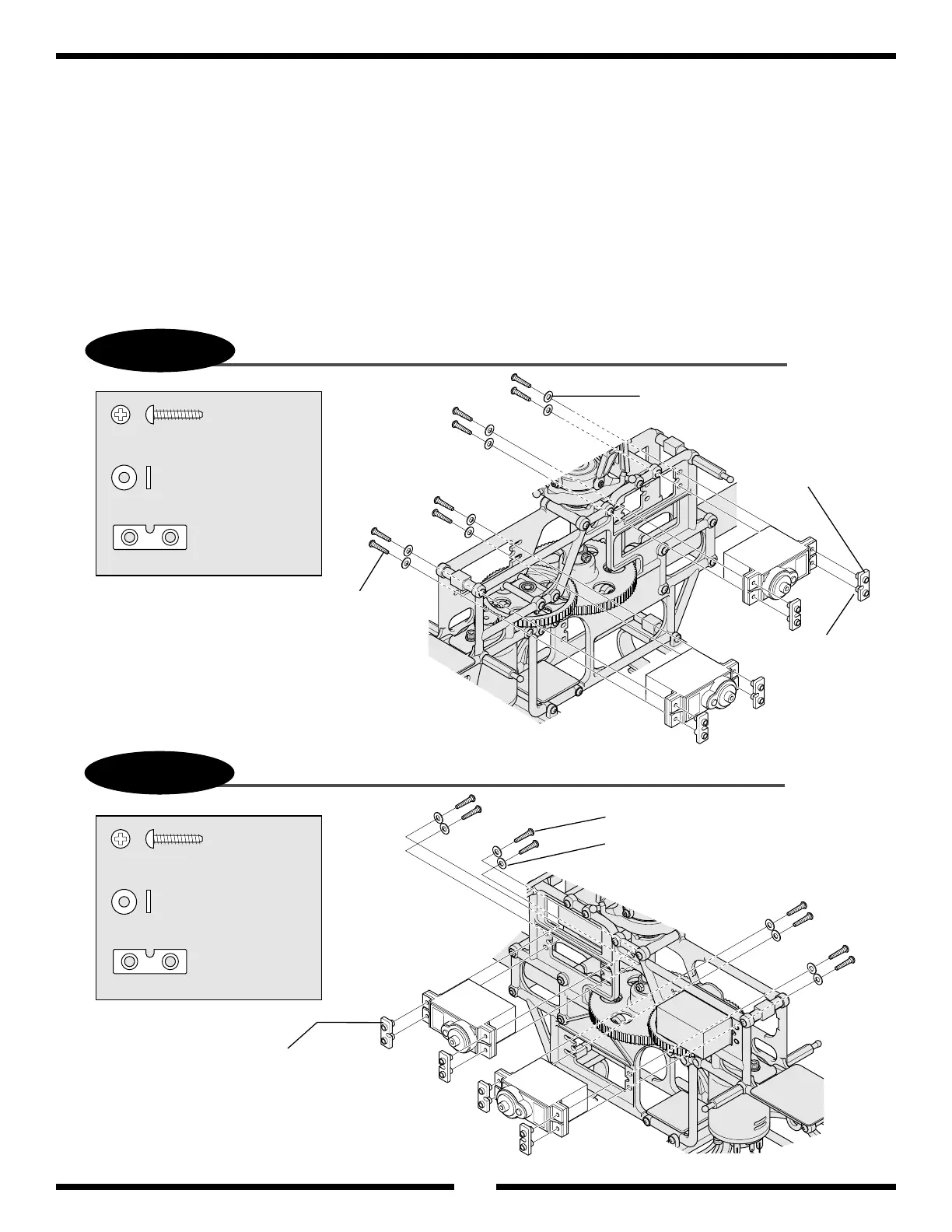

....................... 8 pcs

2.6 x 12 mm Self Tapping Screw

......................................... 8 pcs

2.6 mm Flat Washer

.............................. 4 pcs

Servo Mounting Plate

Servo Mouting Plate (4)

2.6 x 12 mm Self Tapping Screw (8)

2.6 mm Flat Washer (8)

L

F

R

Rudder

19

Aileron/Elevator Servo Installation (Standard Servos)

Pitch/Rudder Servo Installation (Standard Servos)

Servo Installation and Linkage Suggestions

• Use caution not to overtighten the servo mounting screws. The servos

should be able to be moved slightly within the grommets so that they

have a slight amount of

vibration absorption.

• Note the correct direction of the servo output shaft as shown in the

diagrams. If the servos are installed in the incorrect direction, the

linkages will not connect properly.

• Check to insure that all control rods have been adjusted to the proper

lengths as shown in the manual.

• Install the receiver, gyro, and speed controller using double-sided servo

tape as suggested. Please make sure that the cases of these components

do not come in direct contact with other parts of the model.

• Bundle all wires neatly using nylon ties as recommended. Check to

make sure that they cannot become tangled in the gearing or moving

control system parts of the model.

Note: Fit the long flanged portion of the servo

mounting plate B into the rubber servo grommets.

Fit the long flanged portion of the servo mounting

plate B into the rubber servo grommets.

Loading...

Loading...