7.2 Instructions to be observed before commissioning

Incorrect or improper commissioning can cause injury to persons and damage to the machine.

➤ Commissioning may be carried out only by authorised installation and service personnel who

have been trained on this machine.

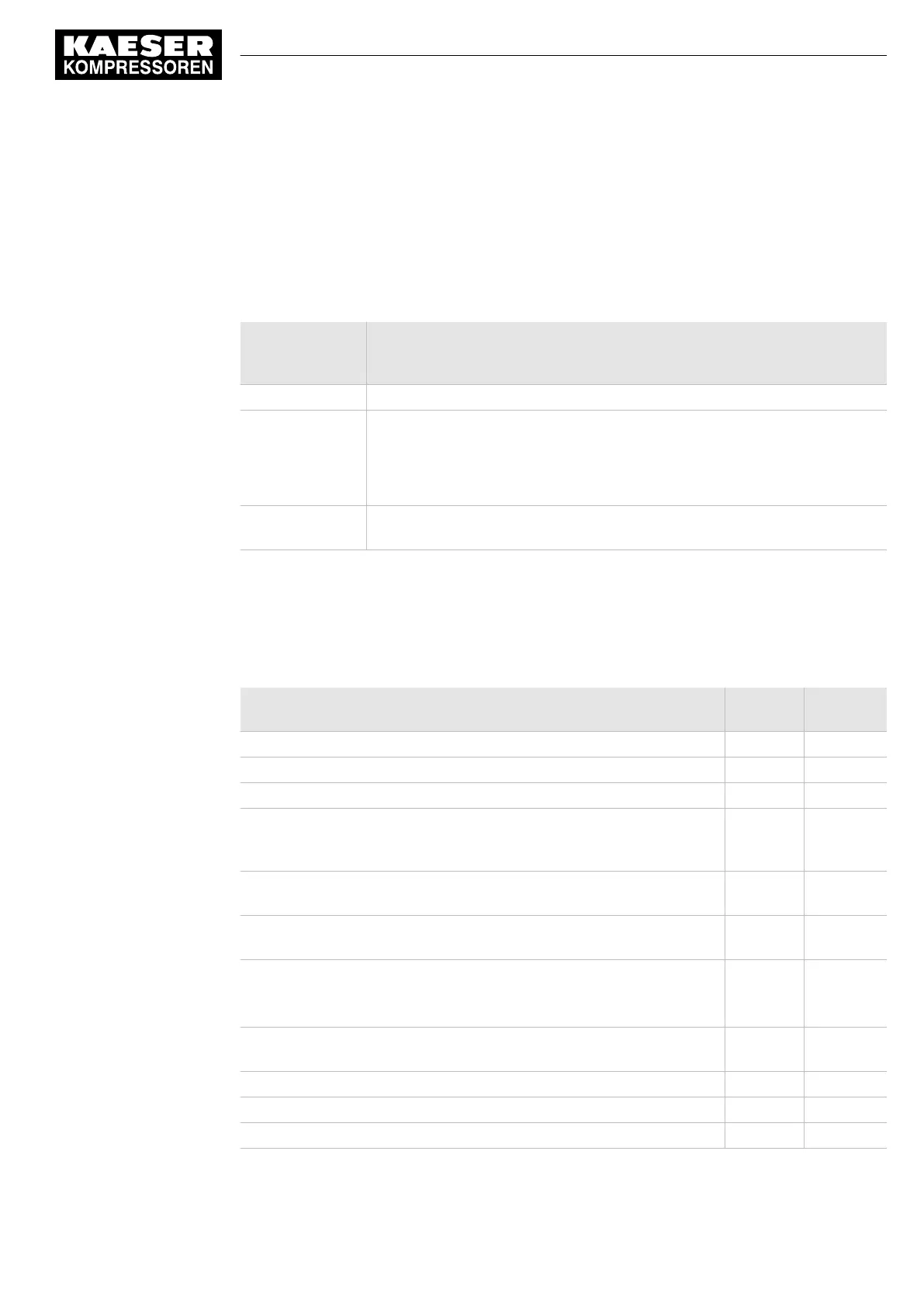

Special measures for re-commissioning after storage/standstill

Storage period/

standstill period

longer than

Measure

3 months ➤ Manually fill the airend with cooling oil.

12 months ➤ Change the oil filter.

➤ Change the oil separator cartridge.

➤ Change the cooling oil.

➤ Manually fill the airend with cooling oil.

36 months ➤ Have the overall technical condition checked by an authorised

KAESER SERVICE technician.

Tab. 41 Re-commissioning after storage/standstill

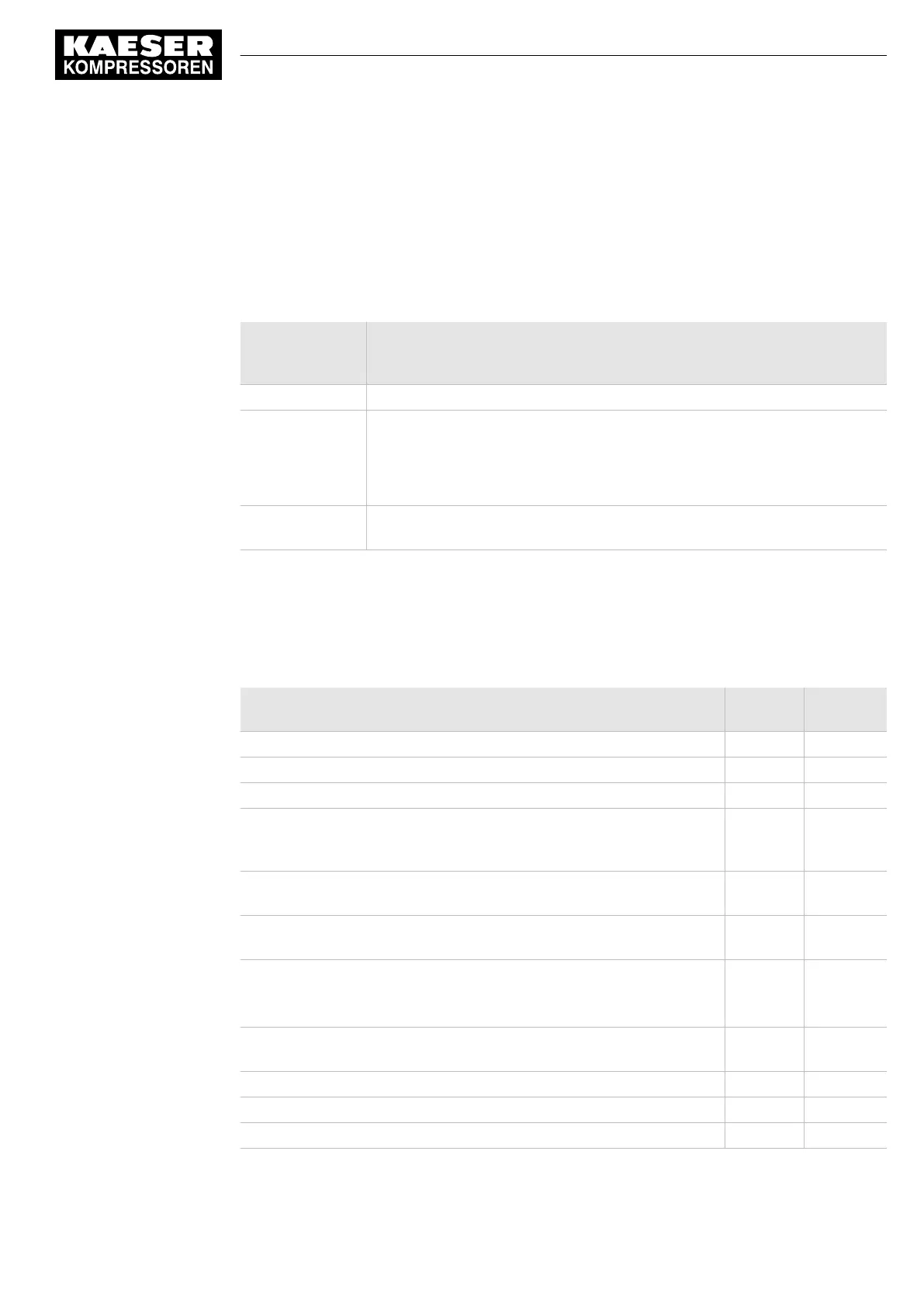

7.3 Checking installation and operating conditions

➤ Check and confirm all the items in the checklist before commissioning the machine.

To be checked See

chapter

Confirmed?

➤ Are the operators fully conversant with safety regulations? –

➤ Have all the positioning conditions been fulfilled? 5

➤ Is a user's lockable power supply disconnecting device installed? 6.5

➤ Are the tolerance limits of the mains voltage (power supply) within

the permissible tolerance limits of the rated voltage (machine)?

(see nameplate in the control cabinet)

13.4

➤ Are the power supply cable conductor cross-sections and fuse rat‐

ings adequate?

2.14

➤ Drive motor overload protection switch set according to the mains

voltage?

7.4

➤ Have all electrical connections been checked for tightness?

➤ Has the inspection been repeated after 50 operating hours following

the initial commissioning?

–

➤ Has the connection to the air system been made with a shut-off valve

and a flexible hose?

6.3

➤ Has the drive belt tension been checked? 10.9

➤ Is there sufficient cooling oil in the separator tank? 10.13

➤ Is there sufficient cooling oil in the airend? 7.5

7 Initial Start-up

7.2 Instructions to be observed before commissioning

901848 21 E

Operating Manual Rotary screw compressor

SK

43

Loading...

Loading...