10.7 Air Filter Maintenance

Check that all sealing surfaces match each other. The use of an unsuitable air filter element

can permit dirt to ingress the pressure system and cause damage to the machine.

The air filter element cannot be cleaned.

Material Replacement part

Precondition The power supply disconnecting (isolating) device is switched off,

the disconnect device is locked in the off position,

a check has been made that no voltage is present.

The machine has cooled down.

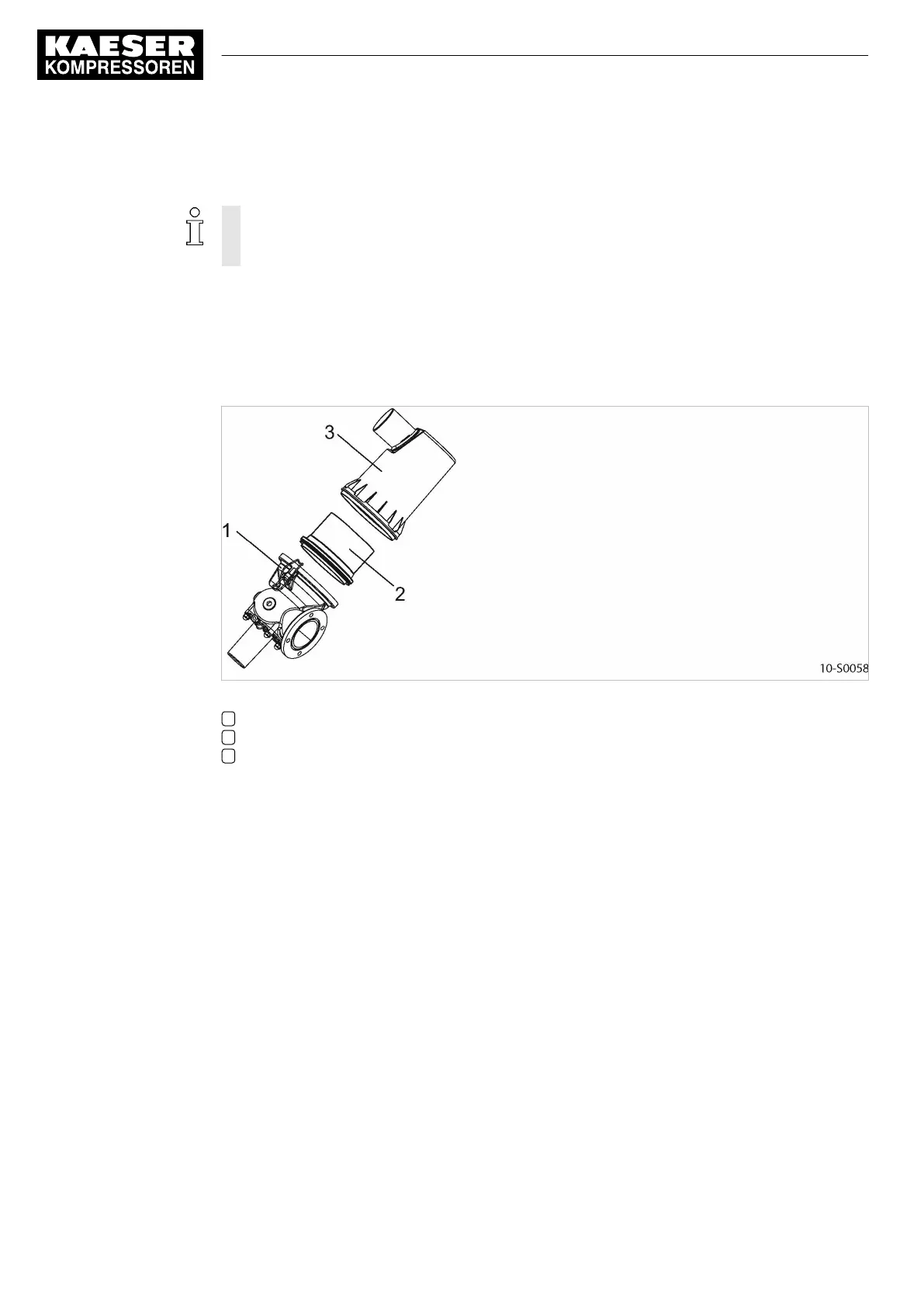

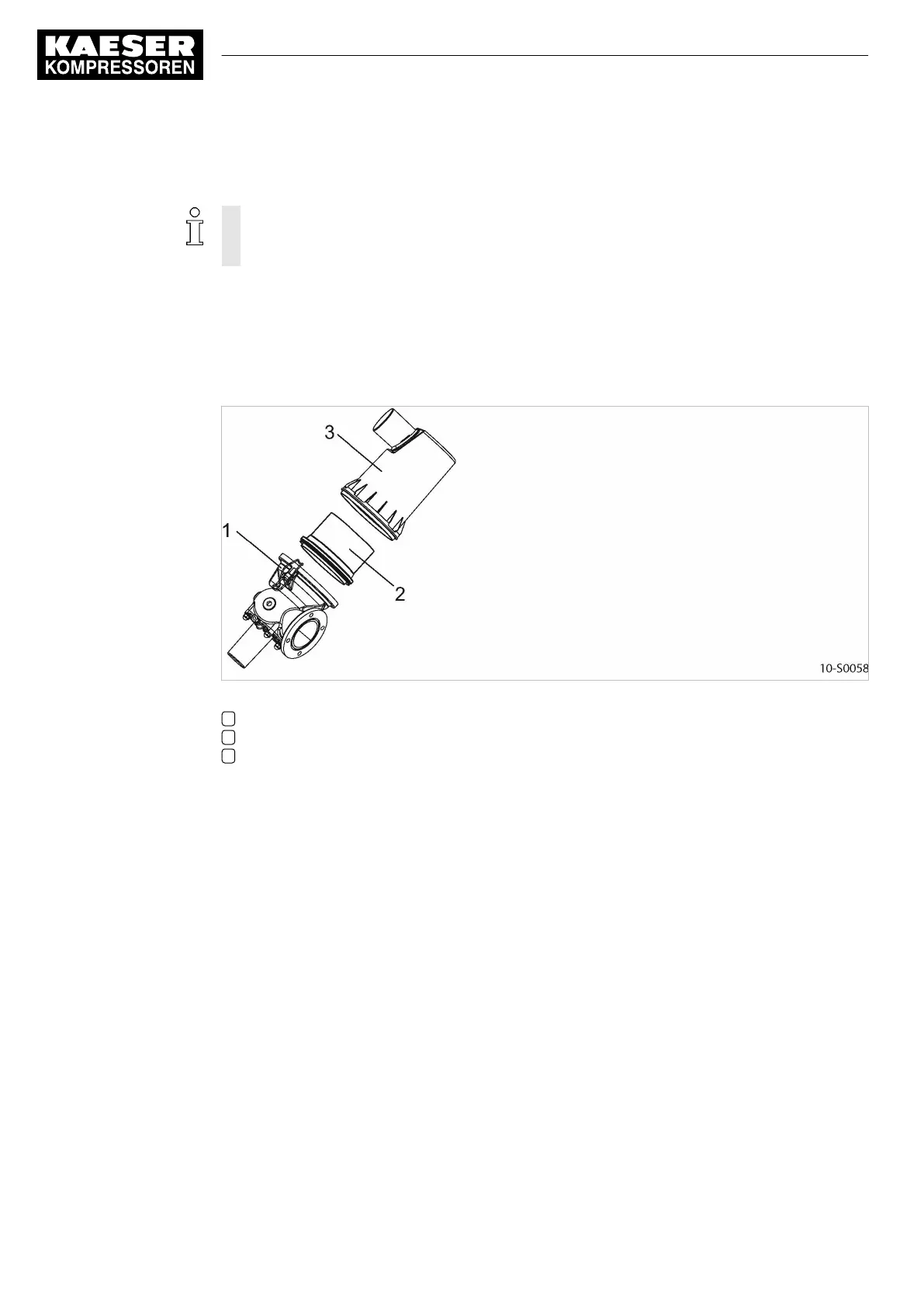

Fig. 22 Air filter maintenance

1 Snap fastener

2 Air filter element

3 Air filter housing

1. Release the spring clips and remove the element.

2. Clean all parts and sealing surfaces.

3. Insert the new element in the housing.

4. Clip the air filter housing onto the inlet valve.

10.8 Compressor motor maintenance

The anti-friction bearings of the compressor motor are permanently greased. Re-greasing is not

necessary.

➤ Have the anti-friction bearings checked by an authorised KAESER SERVICE technician in the

course of a maintenance visit.

10 Maintenance

10.7 Air Filter Maintenance

62

Operating Manual Rotary screw compressor

SK 901848 21 E

Loading...

Loading...