10.9 Drive belt maintenance

Material Spare parts (if required)

Precondition The power supply isolating device is switched off,

the device is locked off,

the absence of any voltage has been verified.

The machine has cooled down.

WARNING

Touching the moving drive belt may result in severe bruising or even loss of limb or extremi‐

ties.

➤ Switch off and lock out the power supply isolating device and verify the absence of volt‐

age.

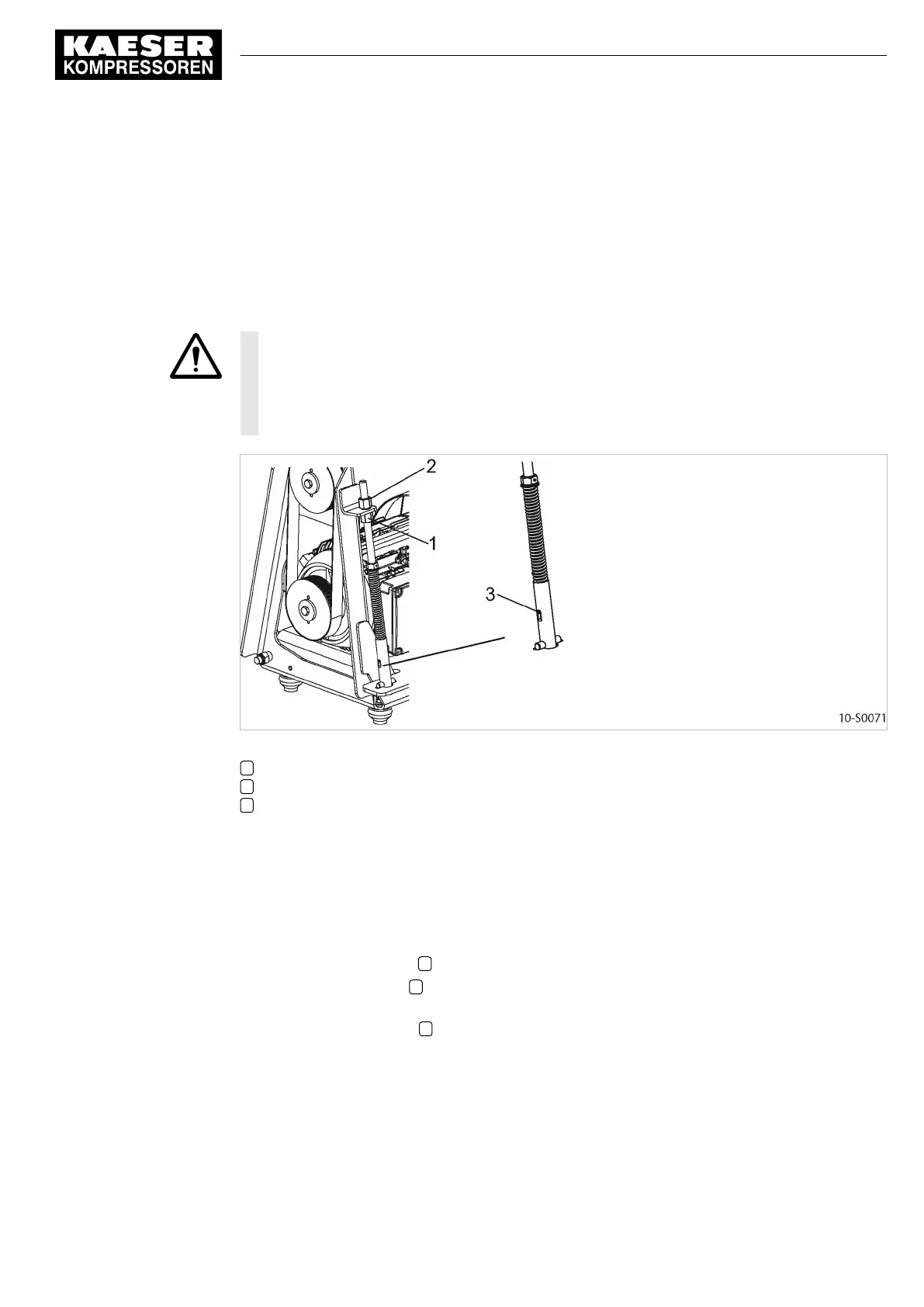

Fig. 23 Drive belt maintenance

1 Clamping nut

2 Clamping nut

3 Marker pin (shown as: belt tensioning required)

Checking the belt tension and adjustment

The tensioning device uses spring force to apply correct tension to the belt.

Adjust the tension when the marker pin reaches the top end of the elongated hole.

The marker pin can be seen through a viewing window from outside. This means that belt tension

can be checked without opening the machine.

1. Loosen the locking nut 2 .

2. Use the adjusting nut 1 to adjust the spring tension until the marker pin reaches the lower end

of the elongated hole.

3. Tighten the locking nut 2 .

Visually check for damages.

1. Turn the pulley by hand so that all of the belt can be inspected for damage.

2. In case of damage: Replace the drive belt immediately.

10 Maintenance

10.9 Drive belt maintenance

901848 21 E

Operating Manual Rotary screw compressor

SK

63

Loading...

Loading...