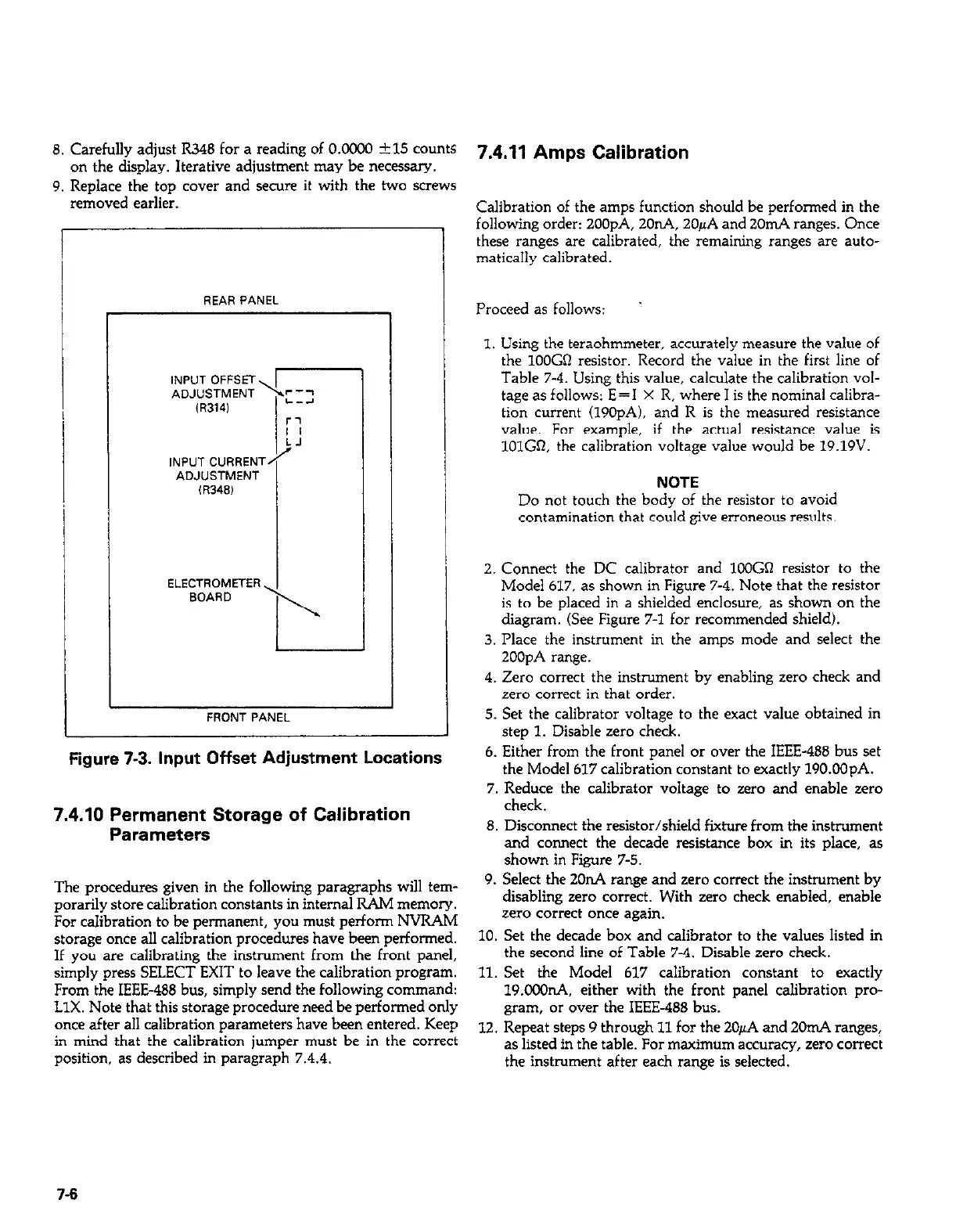

8. Carefully adjust R348 for a reading of 0.0030 215 count5

on the display. Iterative adjustment may be necessary.

9. Replace the top cover and secure it with the two screws

removed earlier.

REAR PANEL

._

::

INPUT CURRENT

i’

ADJUSTMENT

,R348,

ELECTROMETER

BOARD

I

I

FRONT PANEL

Figure 7-3. Input Offset Adjustment Locations

7.4.10 Permanent Storage of Calibration

Parameters

The procedures given in the following paragraphs will tem-

porarily store calibration constants in internal RAM memory.

For calibration to be permanent, you must perform NVRAM

storage once all calibration procedures have been performed.

If you are calibrating the instrument from the front panel,

simply press SELECT EXIT to leave the calibration program.

From the IEEE-488 bus, simply send the following command:

LlX. Note that this storage procedure need be performed only

once after all calibration parameters have been entered. Keep

in mind that the calibration jumper must be in the correct

position, as described in paragraph 7.4.4.

7.4.11 Amps Calibration

Calibration of the amps function should be performed in the

following order: 2OOpA, 2OnA, 20pA and 2OmA ranges. Once

these ranges are calibrated, the remaining ranges are auto-

matically calibrated.

Proceed as follows:

’

1. Using the teraohmmeter, accurately measure the value of

the lOOGO resistor. Record the value in the first line of

Table 7-4. Using this value, calculate the calibration vol-

tage as follows: E=I X R, where I is the nominal calibra-

tion current (190pA). and R is the measured resistance

value. For example, if the actual resistance value is

lOlGR, the calibration voltage value would be 19.19V.

NOTE

Do not touch the body of the resistor to avoid

contamination that could give erroneous results.

2. Connect the DC calibrator and lOOGO resistor to the

Model 617, as shown in Figure 7-4. Note that the resistor

is to be placed in a shielded enclosure, as shown on the

diagram. (See Figure 7-l for recommended shield).

3. Place the instrument in the amps mode and select the

2OOpA range.

4. Zero correct the instrument by enabling zero check and

zero correct in that order.

5. Set the calibrator voltage to the exact value obtained in

step 1. Disable zero check.

6. Either from the front panel or over the IEEE-488 bus set

the Model 617 calibration constant to exactly 190.OOpA.

7. Reduce the calibrator voltage to zero and enable zero

check.

8. Disconnect the resistor/shield fixture from the instrument

and connect the decade resistance box in its place, as

shown in Figure 7-S.

9. Select the 2OnA range and zero correct the instrument by

disabling zero correct. With zero check enabled, enable

zero correct once again.

10. Set the decade box and calibrator to the values listed in

the second line of Table 7-4. Disable zero check.

11. Set the Model 617 calibration constant to exactly

19.ooOnA. either with the front panel calibration pro-

gram, or over the IEEE-488 bus.

12. Repeat steps 9 through 11 for the 20pA and 2OmA ranges,

as listed in the table. For maximum accuracy, zero correct

the instrument after each range is selected.

7-6

Loading...

Loading...