KLR.950 Revision: 2023-10-06

Serial numbers: 3008 – beyond

KLR.00001 – beyond

27

6.0: MAINTENANCE AND CLEANING

6.1: Preventive maintenance schedule

Here is a quick way to take care of your machine by a preventive maintenance schedule. Due to the

complexity of our machine, take note that these procedures are only advices and are subject to change.

These time intervals will change according to the usage of the machine:

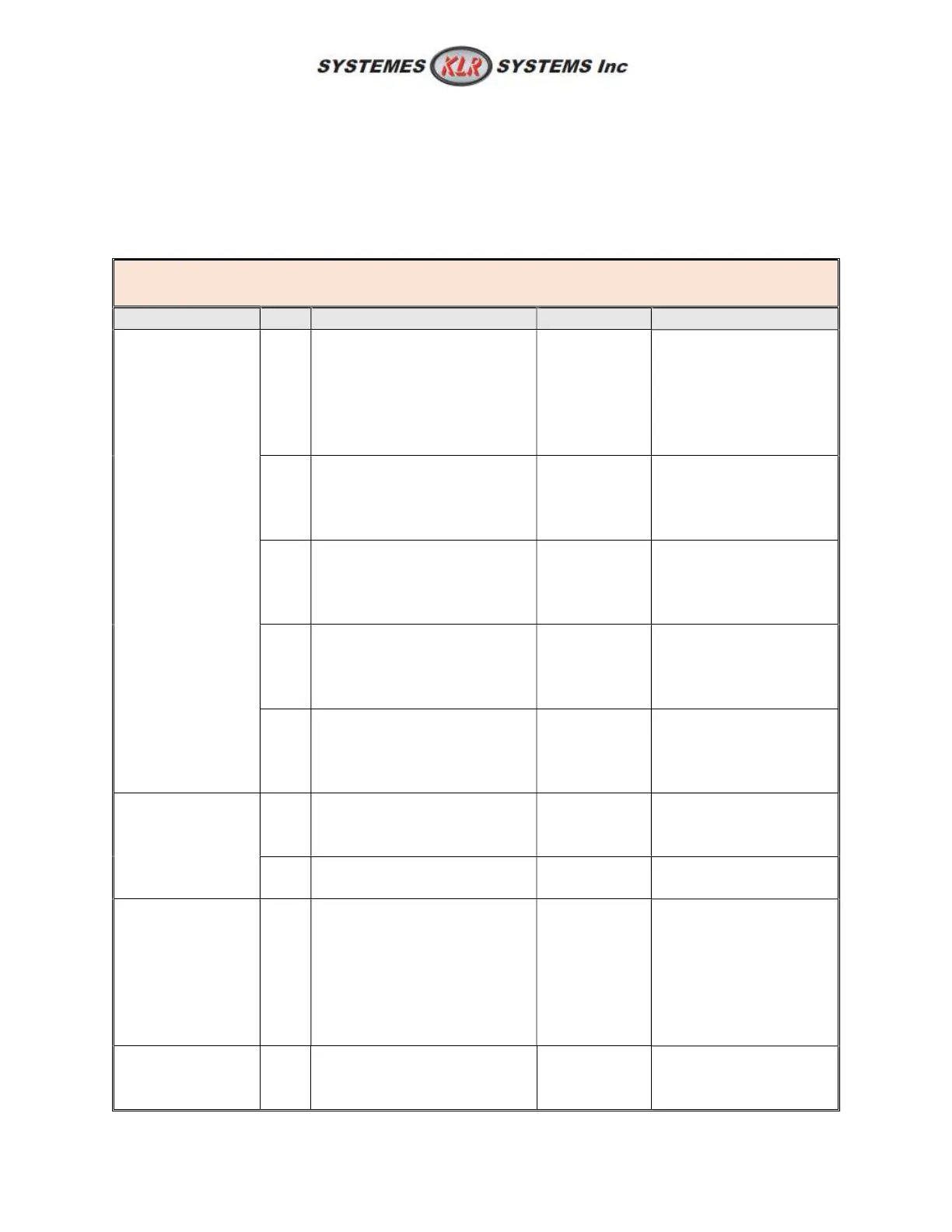

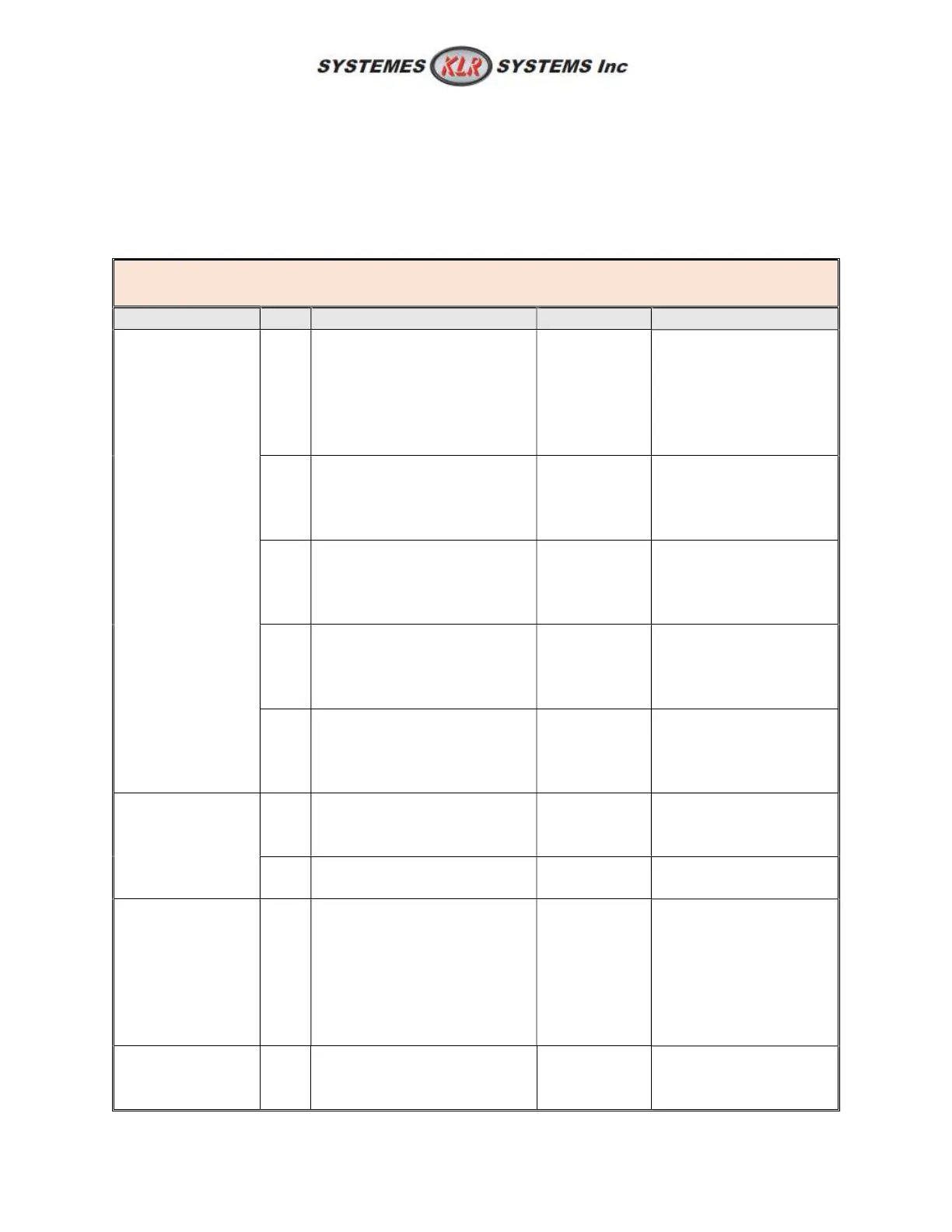

SCHEDULE

belt guide

Check tension and wear on

four (4) toothed belts,

Change belts

according to

the working

time.

corners and

manufacturer printing is

gone. Replace on these

signs for maximum

performance.

Inspect the sprockets and idle

changing

Sprocket must be slid fit

into the spline shaft.

Make sure the set screw

is tight on the sprocket.

Inspect rear bogey bearing.

Remove front plate, check for

shaft play inside inner

bearing

rupture if not addressed

frequently enough

Test bag sensor lever. Make

sure it is free to move

because a bag has

pulled out the wrong

way

the bag when engaged

you should not be able

to pull off the bag with

a moderate effort

Remove rear panel. Look the

gears wear and lubricate (pea

sized of grease on small gear)

chips. Lubricate the

gearing and cycles

right in place

ONLY-

Breaking

mechanism

plate

cuts or signs

of ragged cut

or cutter has

no longer

sharp edges

technically 4 lifes, can

be rotated 4 times

before replacing. New

cutter have technically 2

lifes if put on opposite

machine.

supply. NOT A wash-

down machine.

Loading...

Loading...