- 42 -

KD 625-2 Workshop Manual_cod. ED0053029380_1° ed_ rev. 00

4

70

71 72

69

68

Disassembly / Reassembly

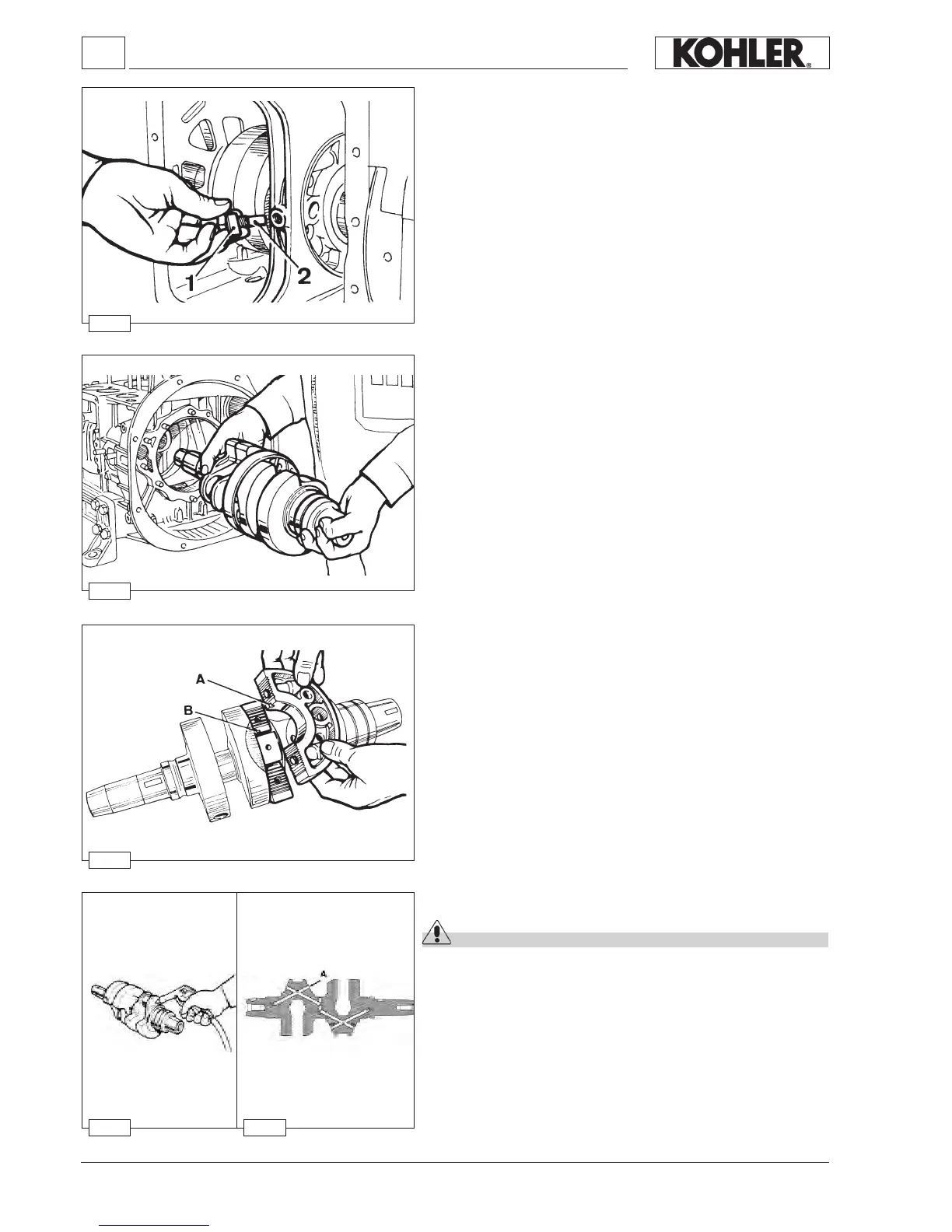

Crankshaft center main bearing support

When retting, both centering notches A and B must be located on the

same side.

Tighten screws at 25 Nm.

See page 44 ÷ 45 for dimensions.

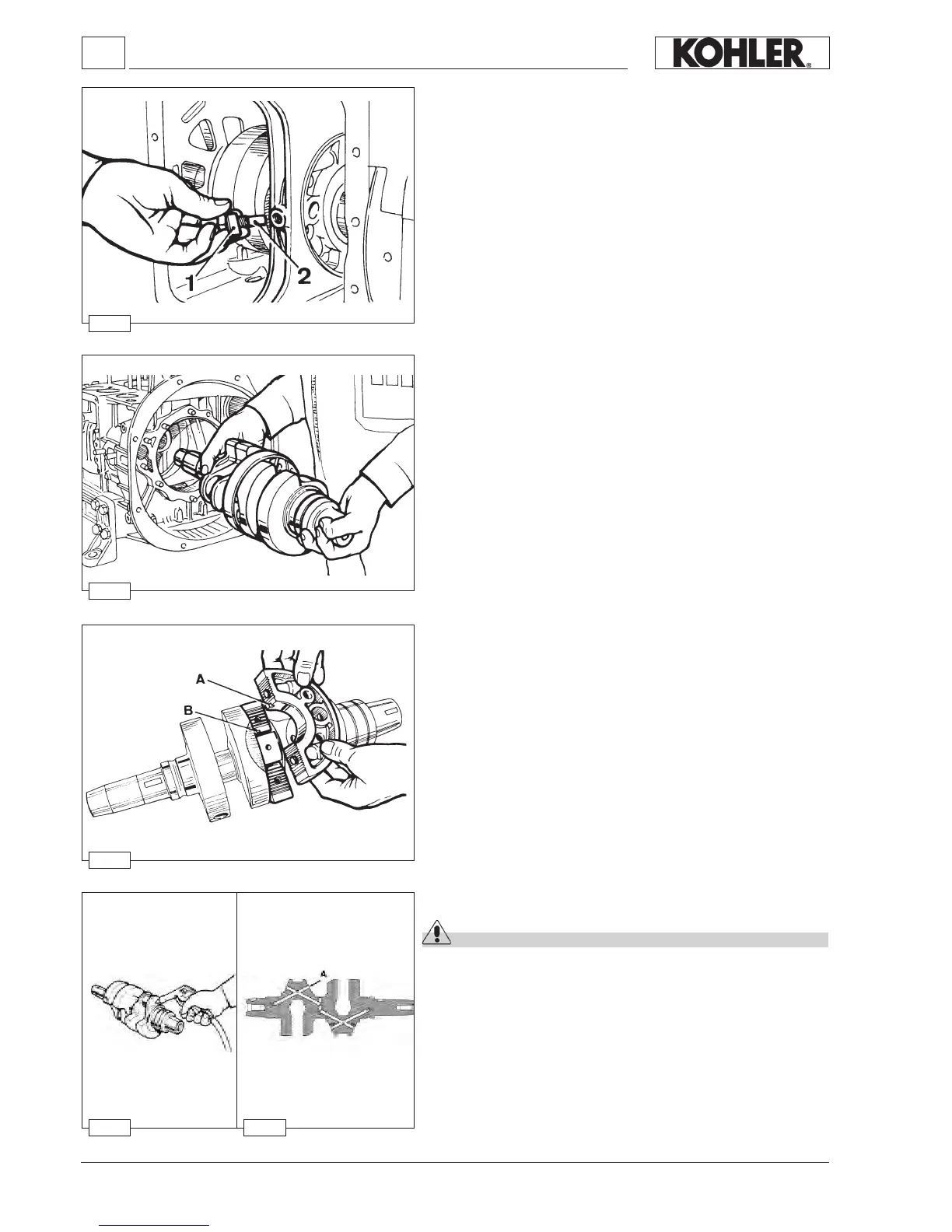

Crankshaft lubrication ducts

Danger - Attention

During repair operations, when using compressed air, wear eye

protection.

Remove plugs, clean duct A with a pointed tool and blow in compressed

air. Screw plugs again and check for sealing.

Crankshaft removal

To pull out the crankshaft tap lightfy on the timing side end using a

copper-headed hammer.

When retting align center main bearing support so that the locating

screw hole coincides with the crankcase hole.

CRANKSHAFT

Center main bearing support, locating screw.

Straighten plate 1 and unscrew screw 2 before removing crankshaft.

When assembling tighten the screw at a torque of 30 Nm.

Loading...

Loading...