BA 35203_04 * 3.0 * 35203_04_05_Bedienung.fm 5-107

Operation 5

Bucket repositioning (option)

The bucket repositioning function can be used for performing cyclical work

(for example for loading trucks) efficiently and with minimum impact to the

material: by pressing a button, the attachment is automatically positioned

from the tilt-out position to the preset work position (for example a

horizontal bucket base).

However, the efficiency of the bucket repositioning is ensured only if the

attachment and the position of sensor A on the tilt ram are adjusted to

each other.

This adjustment is performed easily by means of the marks (notches) on

bracket B (see assignment of notch to attachment in table below)

Before putting the automatic bucket repositioning into operation, switch off

the tilt ram lock (option)!

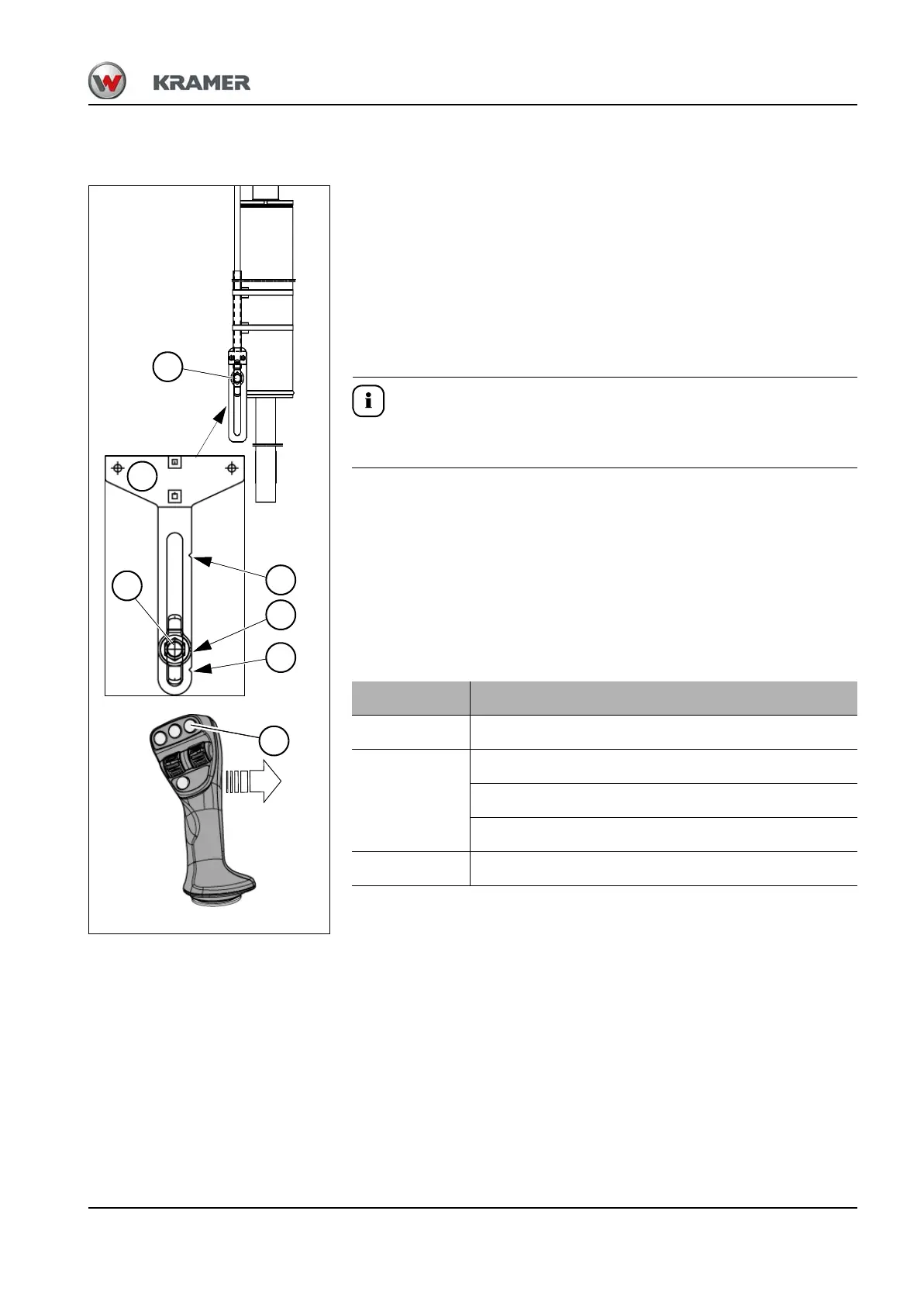

Adjusting the sensor

1. Pick up and lock the attachment in the quickhitch – see “Pick up the

attachment” on page 5-58.

2. Set the attachment to the base position (for example bucket base

aligned horizontally with the ground).

3. Loosen the wing nut on sensor A (sensor bracket on tilt ram).

4. Slide the sensor to the respective mark (notch) on bracket B.

5. Tighten the wing nut.

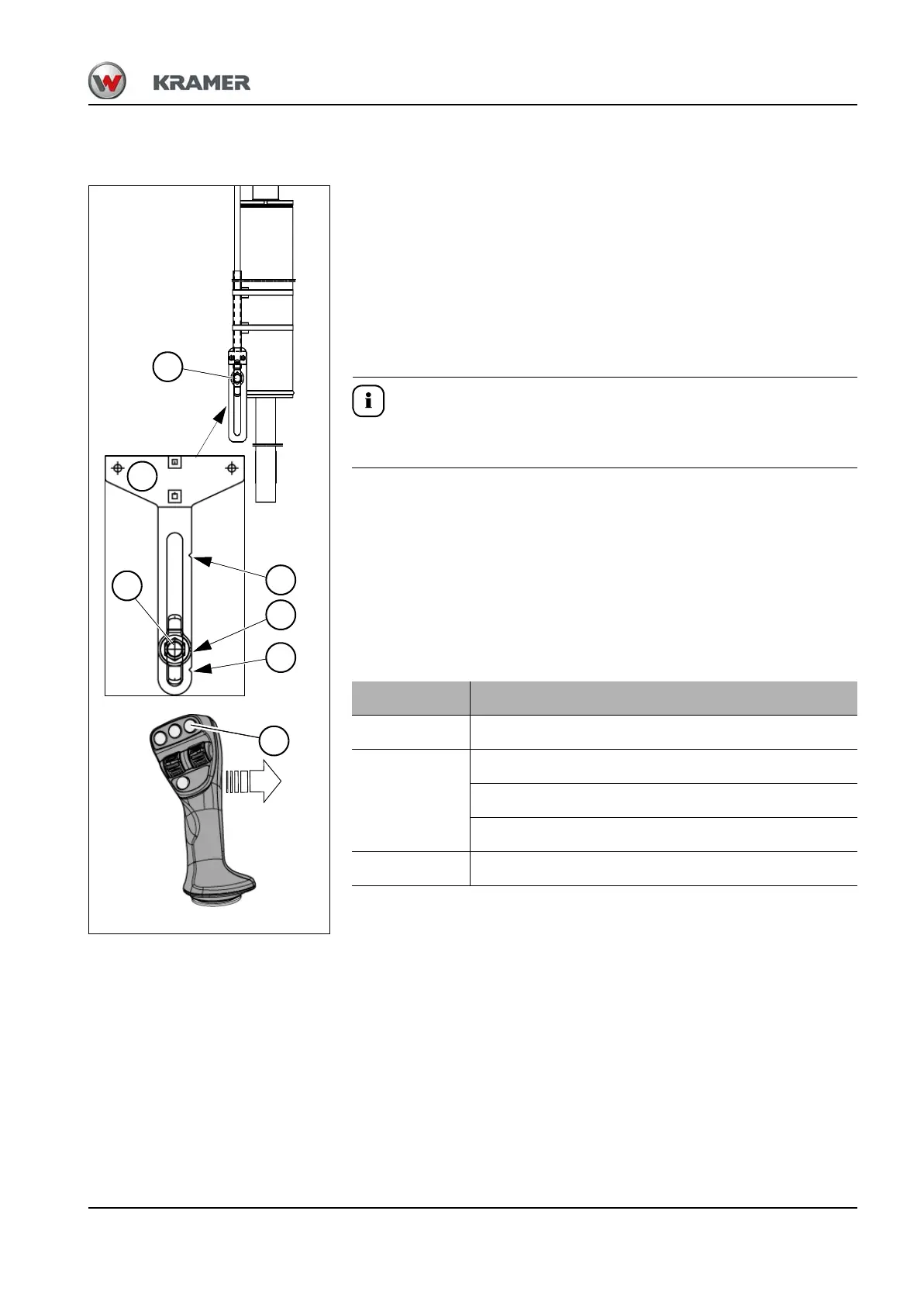

Enabling the bucket repositioning

1. Press touch button 85

on the joystick.

2. The attachment is automatically tilted in to the position that has been

set.

3. Lower the loader unit to load position.

Disabling the automatic bucket repositioning.

1. Press control lever to the right (empty shovel).

Notch Attachments

A Side swing bucket

B

Bucket (normal material)

Bucket (lightweight material)

Multipurpose bucket

C Pallet forks

Loading...

Loading...