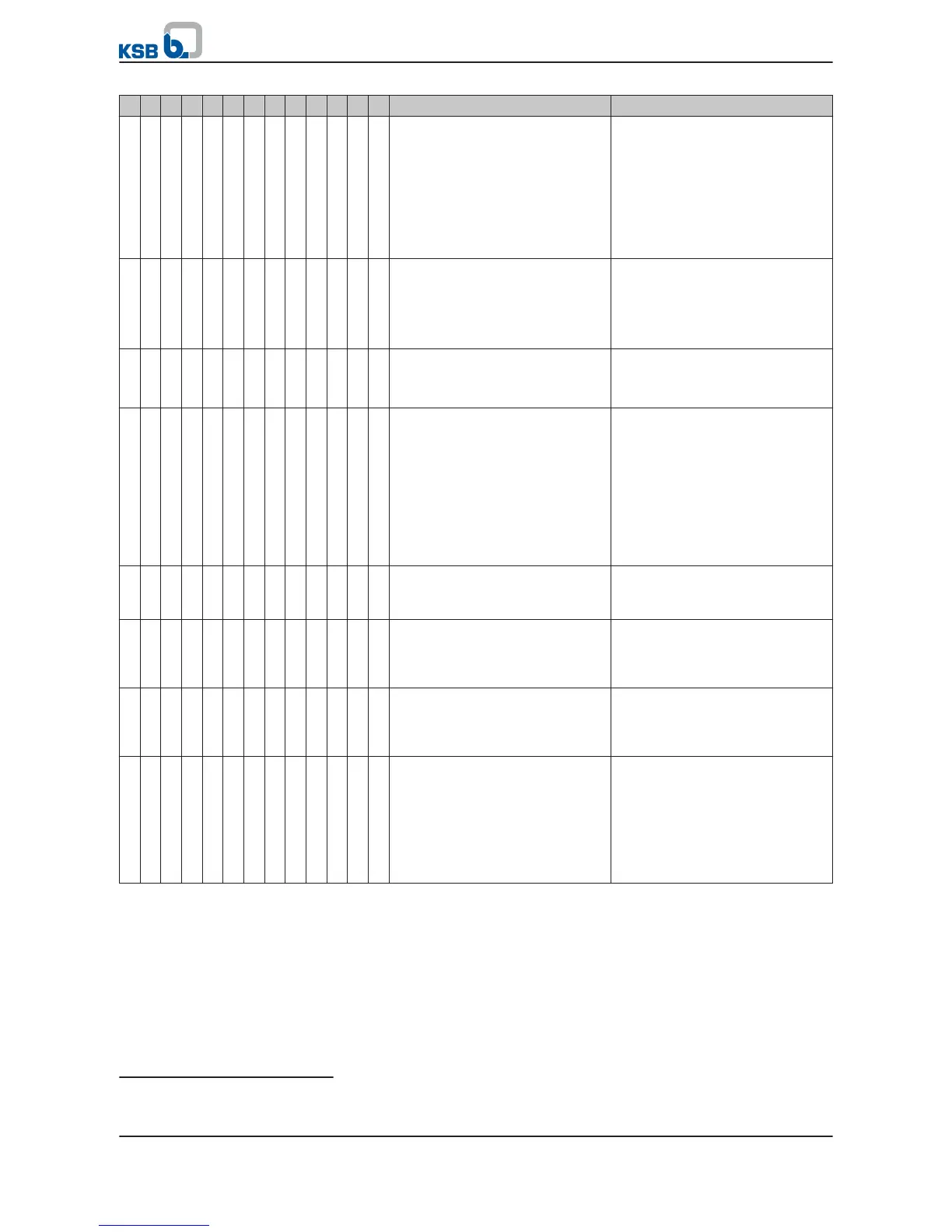

A B C D E F G H I J K L M Possible causes

Remedy

22)

✘ - - ✘ - ✘ ✘ - - - - - - Air intake at the shaft seal ▪ Clean barrier fluid line, supply

external barrier fluid, if

necessary, or increase barrier

fluid pressure.

▪ Check liquid supply system.

▪ Fit new shaft seal.

▪ Replace shaft protecting

sleeve.

✘ - - ✘ ✘ - - ✘ - - - ✘ - Wrong direction of rotation ▪ Interchange two of the phases

of the power cable.

▪ Check electrical connections.

▪ Check impeller position;

correct if necessary.

✘ - - ✘ - - - ✘ - - - - - Speed is too low. ▪ Increase speed.

▪ Check switchgear.

▪ Fit larger impeller.

✘ - - ✘ - ✘ ✘ - - - - - - Wear of internal components ▪ Check duty point/pump

selection.

▪ Increase back pressure by

throttling.

▪ Check fluid handled for

contamination by chemicals;

check solids content.

▪ Replace worn components by

new ones.

- - - - ✘ - - - - - - ✘ - Pump pressure lower than

specified in the purchase order

▪ Re-adjust to duty point.

▪ Increase back pressure by

throttling.

- - - - ✘ - - - - - - ✘ - Density or viscosity of fluid

handled higher than stated in

purchase order

▪ Reduce speed.

▪ In the case of persistent

overloading, turn down

impeller, if possible.

- ✘ ✘ - ✘ - - ✘ - - - ✘ - Speed is too high. ▪ Reduce speed.

▪ In the case of persistent

overloading, turn down

impeller, if possible.

- - - - - - - - - - - - ✘ Assembly bolts/sealing elements ▪ Check.

▪ Re-tighten the bolts.

▪ Fit new sealing elements.

▪ Check pipeline connections

and secure fixing of pump;

improve fixing of pipelines, if

necessary.

22)

Pump pressure must be released before attempting to remedy faults on parts which are subjected to pressure.

8 Trouble-shooting

70 of 94

Omega / Omega V

Loading...

Loading...