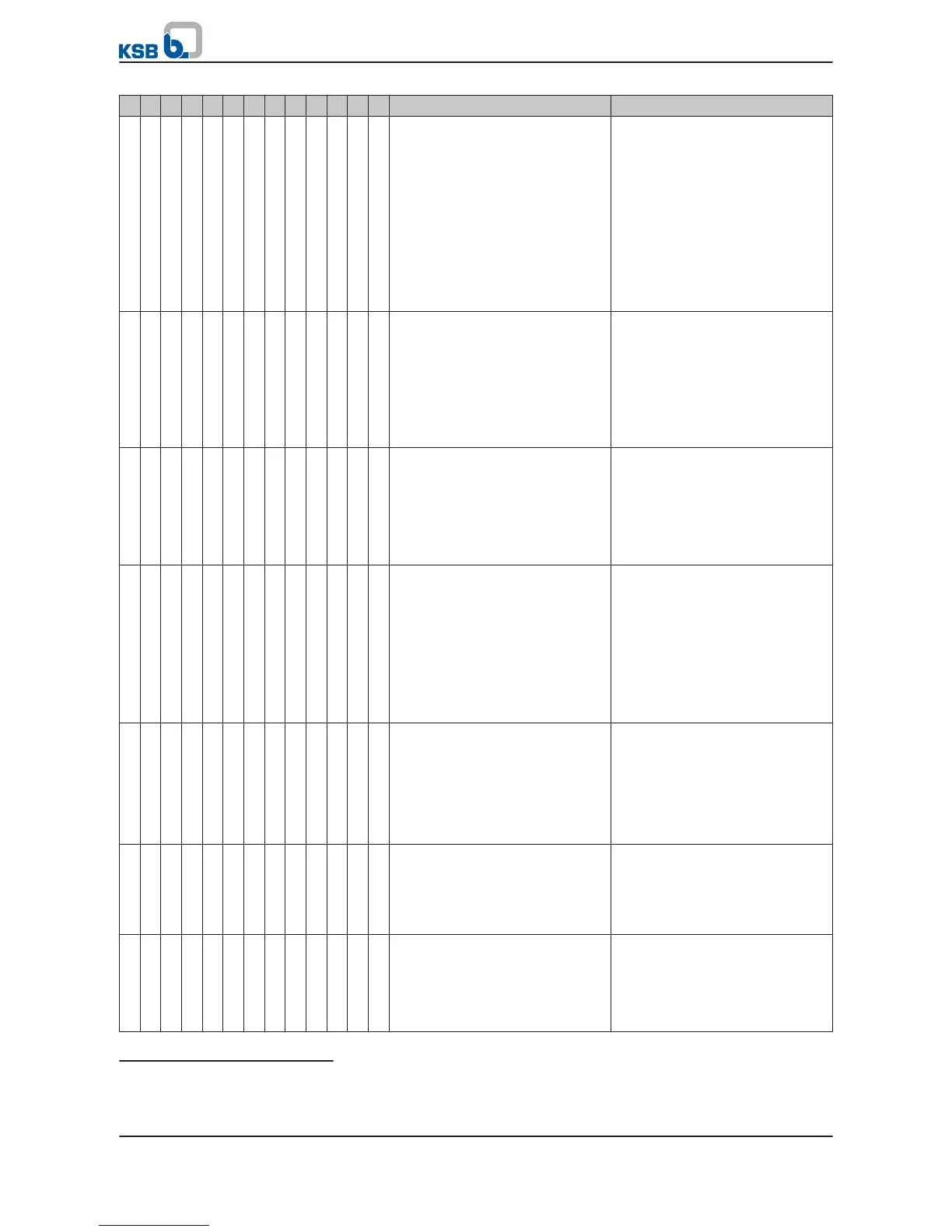

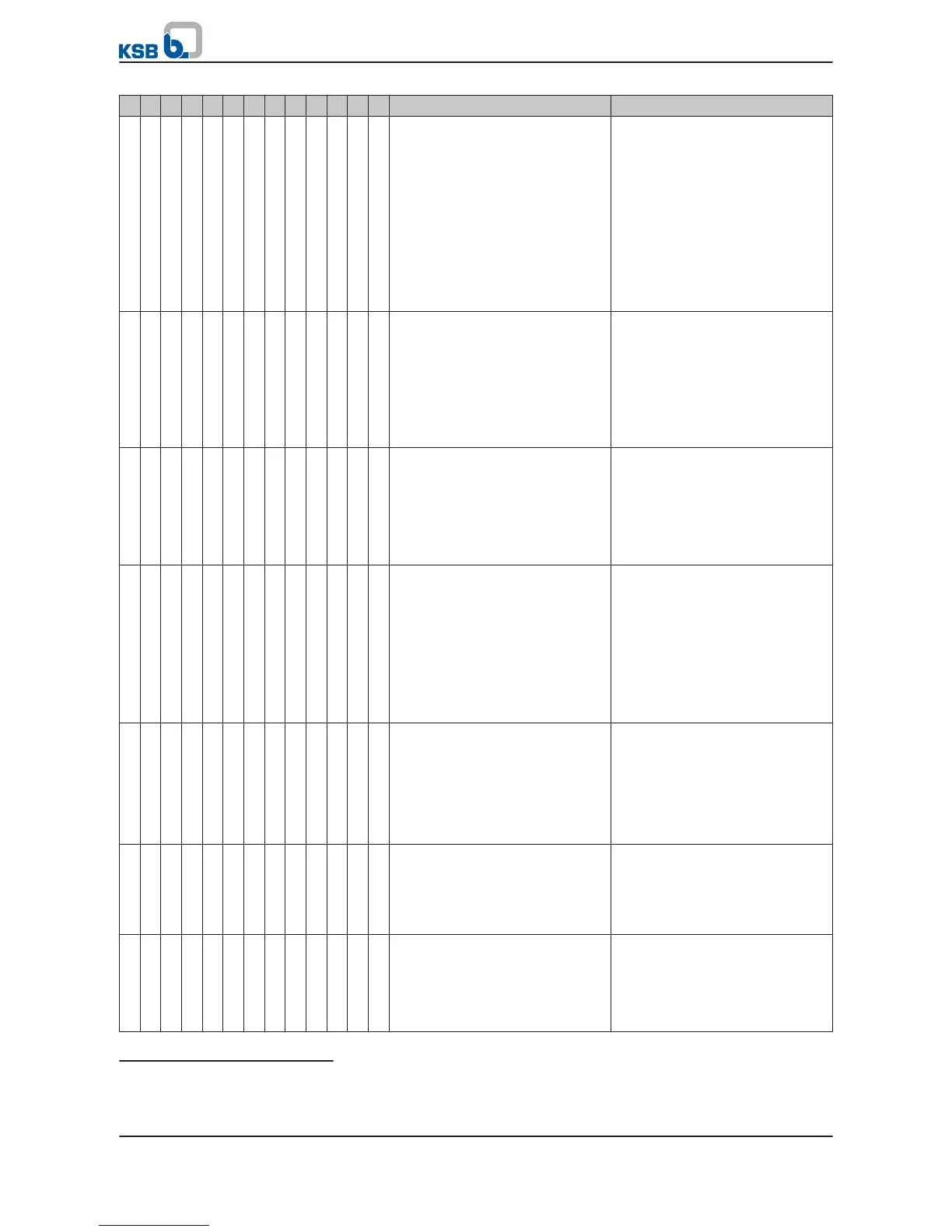

A B C D E F G H I J K L M Possible causes

Remedy

22)

- - - - - - - - - - ✘ - - Worn shaft seal ▪ Check flushing liquid/barrier

fluid pressure.

▪ Clean barrier fluid line, supply

external barrier fluid, if

necessary, or increase barrier

fluid pressure.

▪ Fit new shaft seal.

▪ Replace worn components by

new ones.

▪ Replace shaft protecting

sleeve.

✘ - - ✘ - - - ✘ - ✘ - - - Unfavourable flow to pump

suction nozzle

▪ Alter piping layout.

▪ Alter suction/inlet line, if

piping losses are too high.

▪ Check whether pipe routing

results in swirling or irregular

flow (e.g. downstream of

elbow) and correct, if

necessary.

- - - - - - - - ✘ - ✘ - - Gland follower or seal cover

tightened incorrectly; wrong

packing material.

▪ Adjust.

▪ Replace.

▪ Correct.

▪ Replace gland packing.

▪ Replace worn components by

new ones.

- - - - - - - - ✘ - ✘ - - Lack of cooling liquid or dirty

cooling chamber

▪ Check flushing liquid/barrier

fluid pressure.

▪ Clean barrier fluid line, supply

external barrier fluid, if

necessary, or increase barrier

fluid pressure.

▪ Increase cooling liquid

quantity.

▪ Purify/clean cooling liquid.

- - - - - - - ✘ - ✘ - - - Pump is warped or sympathetic

vibrations in the piping.

▪ Re-align pump/drive.

▪ Check pipeline connections

and secure fixing of pump;

improve fixing of pipelines, if

necessary.

▪ Fix pipelines using anti-

vibration material.

- - - - - - - - - ✘ - - - Increased axial thrust ▪ Check duty point/pump

selection.

▪ Check operating mode.

▪ Check suction-side flow

conditions.

- - - - - - - - - ✘ - - - Insufficient or excessive quantity of

lubricant or unsuitable lubricant

▪ Clean the bearings.

▪ Top up, reduce or change

lubricant.

▪ Check oil lubrication system

23)

.

▪ Check oil supply

23)

.

22)

Pump pressure must be released before attempting to remedy faults on parts which are subjected to pressure.

23)

If any

8 Trouble-shooting

Omega / Omega V

71 of 94

Loading...

Loading...